University of Maine unveils first-ever fully bio-based 3D-printed home to address affordable housing needs.

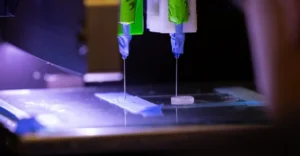

The University of Maine has debuted what could be a game-changing new home design for affordable housing construction. On Nov. 21, the university’s Advanced Structures and Composites Center (ASCC) debuted BioHome3D — the first house in the world of its kind built entirely from bio-based materials.

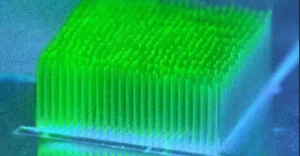

Designed with 600-ft2 of space, this prototype is built with wood fibers and bio-resins, making it a completely recyclable and highly insulated space. The BioHome3D was printed in 4 modules, built on location in one day, and ready for electricity, 2 hours after construction with very little personnel.

“We can build homes much more rapidly and with far less waste using 3D printing to make house s,” said Dr. Habib Dagher, executive director of ASCC.

The bio-based materials, such as wood insulation, could be adjusted for various energy efficiency requirements and climatic areas. “Most of the construction waste that you would see in a typical home-building process is removed from it in the manufacturing process.”

The shortage of affordable housing in the United States is estimated at 7 million homes nationwide. The BioHome3D could be a solution to these deficiencies with its quick building times and lower prices.

Read more : Blue Origin Partners with NCAME for Copper 3D Printing Innovation

The research is supported by the U.S. Department of Energy’s Hub and Spoke program and the design was completed in partnership with the Oak Ridge National Laboratory. As it advances, researchers believe that it could scale up for bigger housing projects and in the process fundamentally change conventional building practices.