Cobra Golf revolutionizes the golf industry with its successful launch of 3D-printed irons and plans for expanded additive manufacturing implementations.

Cobra PUMA Golf claims to have achieved a significant breakthrough in the golf equipment industry with their LIMIT3D irons – reportedly the first commercially available iron set manufactured using 3D printing technology. The June 7, 2024 launch allegedly saw unprecedented demand, with the limited edition run of 500 sets selling out within minutes despite carrying a price tag twice that of conventional models.

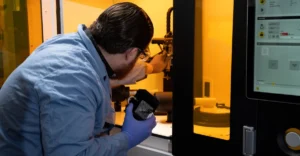

The innovative clubs supposedly owe their performance to a unique construction method using Laser Powder Bed Fusion (LPBF). This technique allegedly allowed Cobra to replace over 100 grams of solid steel with an internal lattice structure, redistributing the mass using tungsten weights to potentially improve the club’s center of gravity and moment of inertia.

Following this claimed success, sources indicate Cobra is preparing to launch the 3DP TOUR iron on March 21st, 2025. This new model supposedly maintains the same characteristics as the LIMIT3D but will be offered at an 18% lower price point, potentially making the technology more accessible to average golfers.

The company’s commitment to additive manufacturing reportedly extends beyond irons. Sources suggest this technology played a crucial role in securing PGA Tour player Max Homa, with Cobra allegedly creating custom sets of irons for testing in just 4 weeks using 3D printing methods.

Cobra appears to be exploring multiple additive manufacturing processes, including HP’s Metal Jet Process, which was supposedly used in their 2020 Supersport 35 putter. The company reportedly utilizes nTop software for computational design workflows, enabling rapid iteration and optimization of internal geometries.

According to promotional materials, Ryan Roach, Cobra Golf’s Director of Innovation, is scheduled to discuss these developments at the Additive Manufacturing Strategies event in New York City on February 4th, 2025, where more details about the company’s expanding use of additive manufacturing may be revealed.