UC Davis researchers develop holographic 3D printing technique using soundwaves to create objects through physical barriers.

Researchers at the University of California, Davis have developed a groundbreaking 3D printing technique that could revolutionize medical treatments and manufacturing, using nothing more than high-pressure soundwaves.

Mohsen Habibi, an assistant professor of mechanical and aerospace engineering, has pioneered holographic direct sound printing (HDSP), a method that can potentially print materials through physical barriers without traditional incisions or complex layering processes.

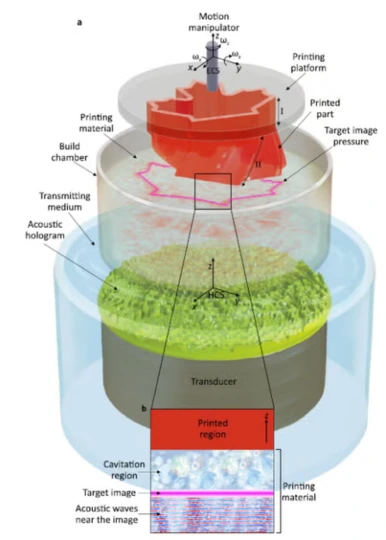

The innovative technique uses acoustic holographic technology to project and solidify entire two-dimensional images simultaneously within a polymer-filled chamber. Unlike conventional 3D printing methods that build objects layer by layer, HDSP can create entire structures in a single moment, significantly reducing production time.

In experimental trials, Habibi demonstrated the technique’s capabilities by creating simple geometric shapes including maple leaf outlines, helixes, and “U” shapes. However, the most promising application lies in potential medical interventions, particularly tissue reconstruction.

“Bone, cartilage and similar biological tissues are not really complex in terms of geometry, so they could be projected with only one image,” Habibi explained. The research suggests a future where medical procedures could be performed without invasive surgical techniques.

The process involves a sophisticated setup: a robotic arm holds a printing platform above a water-submerged transducer. High-acoustic pressure soundwaves create microscopic bubbles through a process called cavitation, which ultimately solidifies the desired shape within the polymer material.

This breakthrough builds upon Habibi’s previous research in direct sound printing (DSP), representing a significant advancement in non-traditional manufacturing techniques. While current capabilities are limited to simple shapes, the potential applications are vast and exciting.

Comparing the technology to science fiction references like Star Trek’s advanced medical bay, Habibi acknowledges the seemingly impossible nature of the research. “When people read the 2022 paper in Nature Communications, they mentioned that direct sound printing was science fiction,” he said with a smile. “This is science over fiction.”

The findings, detailed in the journal Nature Communications, represent a watershed in both the field of additive manufacturing and biomedical engineering, paving the way for applications in medicine and technology that had previously seemed impossible.