Sophisticated 3D printing techniques manufacture highly optimized designs of heat exchangers which substantially enhances the cooling efficiency for specialized and industrial applications.

New 3D-Printed Heat Exchangers Offer Better Cooling Performance

A thermal 3D-printed heat exchanger promises extraordinary efficiency gains, which can completely change the cooling systems of various industries such as naval ships and air conditioners. Funded by the US Department of Naval Research, scientists at the University of Illinois at Urbana-Champaign have developed new devices for thermal management which outperform traditional designs by 50%.

Breaking the Mold with 3D Printing

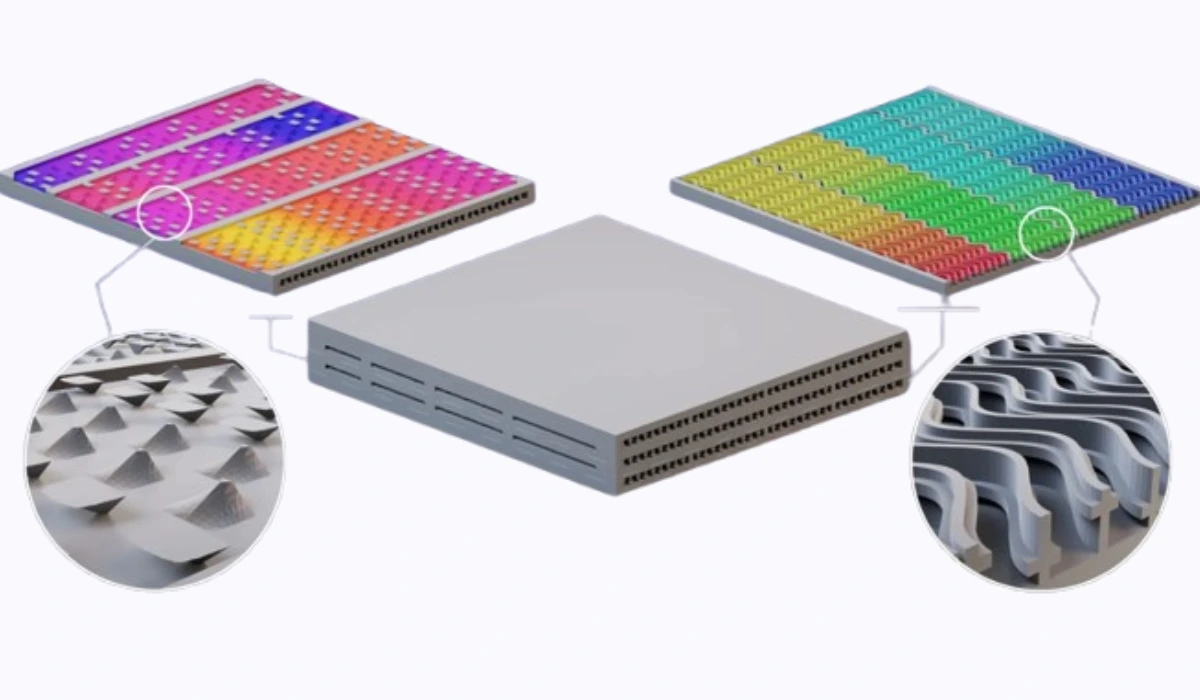

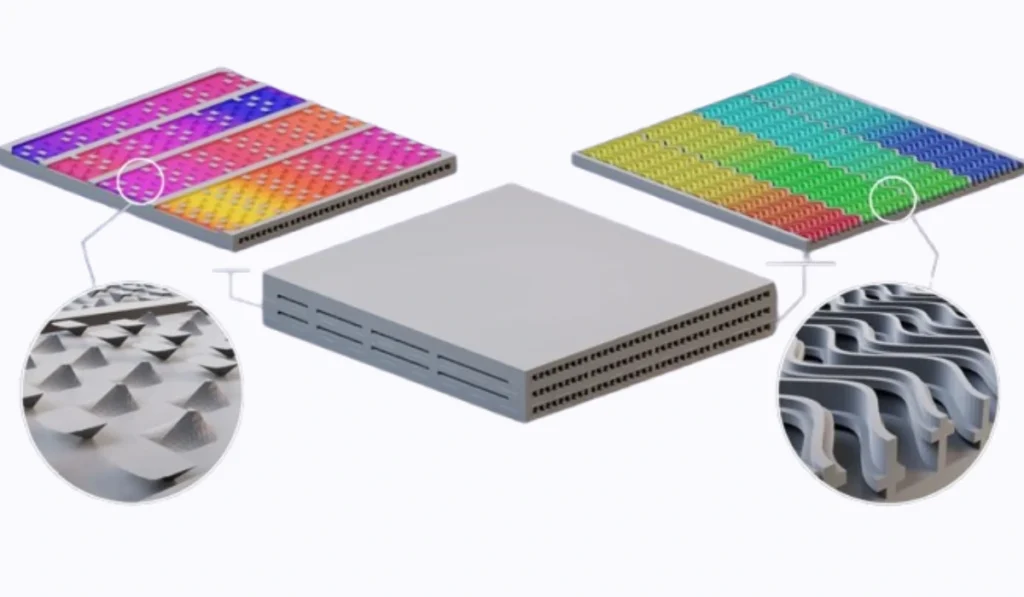

From refrigerators to power plants, all types of machinery possess heat exchangers. This places them at the center of both heating and cooling processes of all devices. Due to certain spatial limitations in production, these devices have primarily used simple configurations with straight lines, right angles, and cylindrical tubes. However, a research group under the direction of Professor William King has developed more complex features such as wavy walls and pyramid-shaped protrusions that enhance heat transfer within the blended systems using 3D printing techniques.

“Heat exchangers are at the center of the industrial economy. They’re essential to every system that moves energy,” says King, co-author of the study. Traditional designs prioritize cost and ease of production, but additive manufacturing enables complex geometries that maximize performance.

Simulations and Machine Learning Pave the Way

To optimize their design, they conducted 36,000 simulations and trained machine learning models to forecast how various configurations would react to differing conditions. The outcome? A slender heat exchanger with thin walls, wavy water channels, and pyramid-shaped protrusions on the refrigerant side.

The mixing and coating inefficiently with liquid, which is a typical problem in conventional systems, is overcome with the introduction of pyramids to improve blending. The meandering passages improve the surface area for better heat transfer. Thermal exchange is delivered on the water side with small protruding fins. “The greater the contact surface area, the faster cooling occurs, similar to lying on ice versus touching it with gloves,” King explains.

Performance Outshines Traditional Designs

In testing, the 3D-printed device achieved a power density exceeding six megawatts per cubic meter, surpassing shell-tube heat exchangers a standard in industry by 30% to 50% under equivalent conditions. It matched the efficiency of brazed plate designs, another common configuration, but in a smaller footprint.

This may not be a great improvement from the current tech available but it demonstrates the value of trying to combine modeling and additive manufacturing,” states Dennis Nasuta, an HVAC authority at Optimized Thermal Systems. “What we can achieve is still largely untapped.”

The Cost of Innovation

While the possibilities around adoption are exciting, several obstacles also exists. For instance, the currently available 3D-printing method, direct metal laser sintering, is exceedingly more costly and time-consuming when compared to welding and stamping production techniques. The household appliances aluminum alloy prototype took several hours to print, which made its use impractical.

Nasuta notes that niche sectors like aerospace, defense, and luxury automotive are more likely to absorb the upfront costs. The U.S. Navy, for instance, faces growing thermal demands as ships pack more electronics. “Next-gen vessels need compact, high-efficiency systems,” says study co-author Nenad Miljkovic.

Read more : Alquist 3D Expands Housing with 3D Printed Concrete

Cooling Demand Heats Up

Improvement in cooling technologies is simply begging for attention. The surge in global temperatures as well as urbanization is forecasted to increase the demand for energy from these air conditioning systems, alone, to double by 2050. At the same time, new data centers, factories, and electric vehicles put additional pressure on the current thermal management systems.

Although 3D printing will not remedy those issues overnight, it does provide a means to develop more sustainable cooling. “Present norms lack an ‘efficiency incentive,’ so even the most basic of preexisting options are not used,” explains Nasuta. “Yet, cheaper prices may mean that additively fabricated products could transform the architecture of industrial design.”

The Road Ahead

Researchers aim to refine materials and printing speed to lower costs. Partnerships with manufacturers could accelerate real-world testing, particularly in high-value sectors. For now, the focus remains on proving scalability.

“This won’t be in your AC next year,” Nasuta cautions. Yet, as 3D printing evolves, its role in cooling systems and the broader energy transition could grow exponentially.

For an economy built on moving heat, the message is clear: innovation is no longer boxed in by traditional manufacturing. With 3D printing, the future of cooling is taking shape, one layer at a time.