Italian yacht manufacturer Pershing collaborates with Caracol to introduce robotic 3D printing in marine superstructure manufacturing.

Designed as a new generation sport utility yacht, the GTX116, developed by the luxury yacht manufacturer Pershing, is the first ever marine vessel to use large-format additive manufacturing (LFAM) in its construction. A major step forward in yacht production, the project was developed in partnership with the Milan-based technology company Caracol.

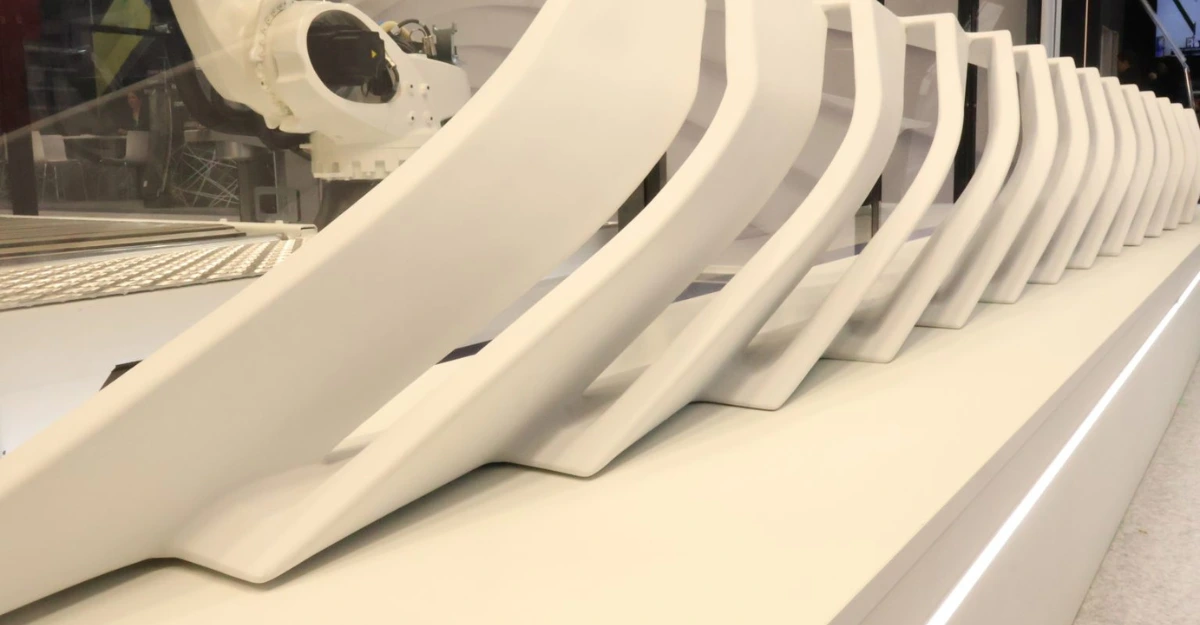

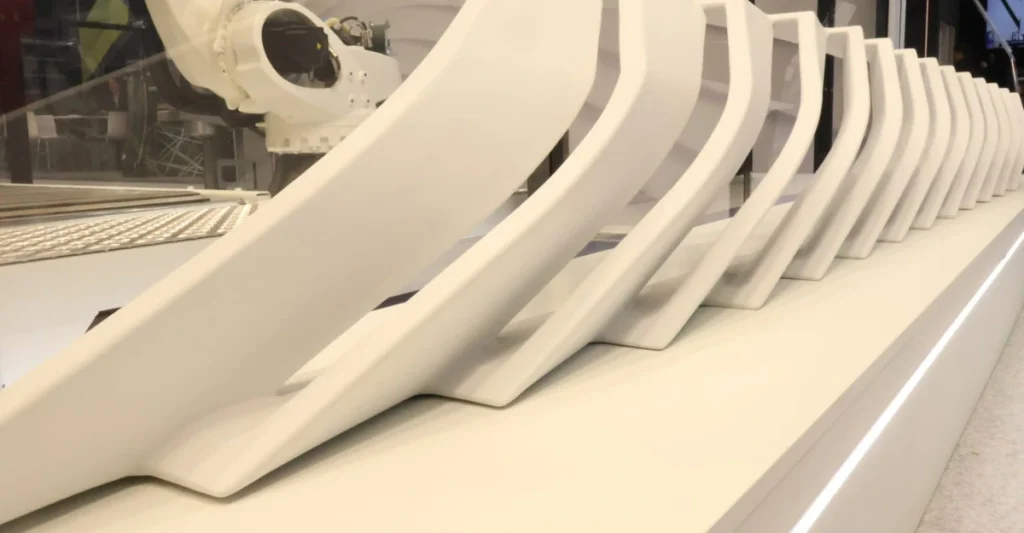

The innovative collaboration focuses on reimagining traditional manufacturing processes, specifically targeting the yacht’s side air intake grilles and windshield visor. Using Caracol’s advanced Heron AM platform, these critical components were fabricated through robotic 3D printing, replacing conventional fiberglass molding techniques.

Key technical specifications highlight the precision of this manufacturing approach. The air grilles, spanning 4.2 meters in length, were printed using ASA material reinforced with 20% glass fiber. The entire printing process, completed in just 72 hours, produced a 40 kg component measuring 420 x 400 x 400 mm. A final gel coat application ensured both durability and aesthetic appeal.

The shift from traditional manufacturing methods offers substantial advantages. Conventional yacht component production typically involves complex mold creation, extensive manual labor, and prolonged lead times. Caracol’s LFAM technology eliminates these constraints, enabling direct computer-aided design (CAD) production with unprecedented design flexibility.

Ferretti Group, Pershing’s parent company, reported remarkable efficiency gains from this new manufacturing approach. The robotic 3D printing technique achieved 50% lead time reduction, 60% reduction in material wastage, and 15% lighter components compared to traditional alternatives. Such improvements are closely aligned with the marine industry’s increasing focus on sustainability and performance optimization.

Caracol, founded in 2017, has developed an integrated LFAM platform combining a proprietary extrusion head, robotic motion systems, and in-house Eidos Manufacturing software. It operates Europe’s largest LFAM centre and has expanded to the United States and Dubai to serve the aerospace, marine, energy and architectural industries.

Additive manufacturing technologies are gaining more and more ground in the marine sector. Notable examples of this include Dutch startup Tanaruz Boats, which makes customizable leisure boats out of recycled polypropylene, and the University of Maine’s 3D-printed vessels in use by the U.S. Marine Corps.

For Pershing and Caracol, the GTX116 project is much more than the production of a single yacht. It showcases a possible paradigm shift in marine manufacturing that shows how advanced technologies can support design, lessen environmental impact and increase production efficiency all at once.

This collaboration between luxury yacht manufacturers and cutting-edge technology firms holds the potential to become the norm, as the maritime industry continues to push the boundaries of advanced manufacturing technologies. Introduced last week, the Pershing GTX116 is a potent demonstration of how robotic 3D printing can change the shaping of the machines we build to create everything else.