Penn engineers pioneer a 3D-printing method to produce dynamic, color-changing smart materials with applications in robotics, medicine, and art.

Engineers at the University of Pennsylvania have developed a new method for 3D-printing of customised plastic objects which can change their colour and properties in response to their environment. The research appears in Advanced Materials and focuses on what are called cholesteric liquid crystal elastomers (CLCEs)—soft, rubbery materials that can be bent, stretched and twisted to produce changes in color.

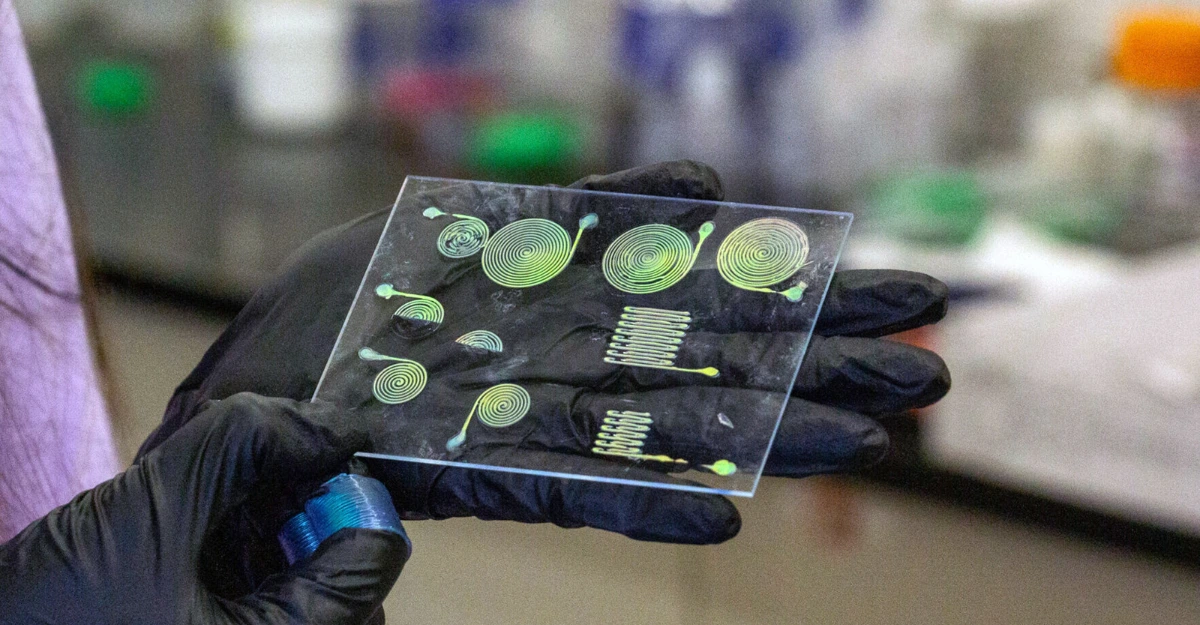

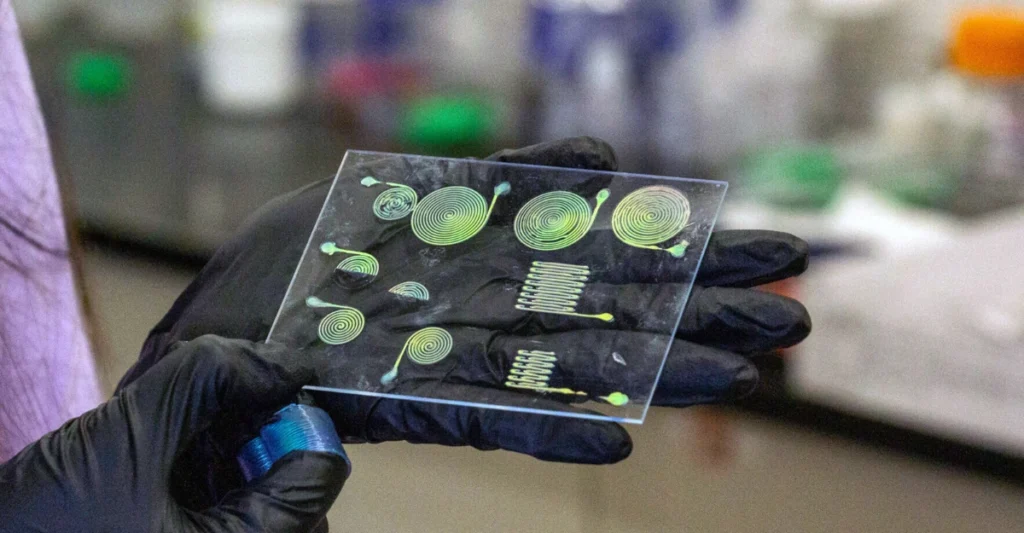

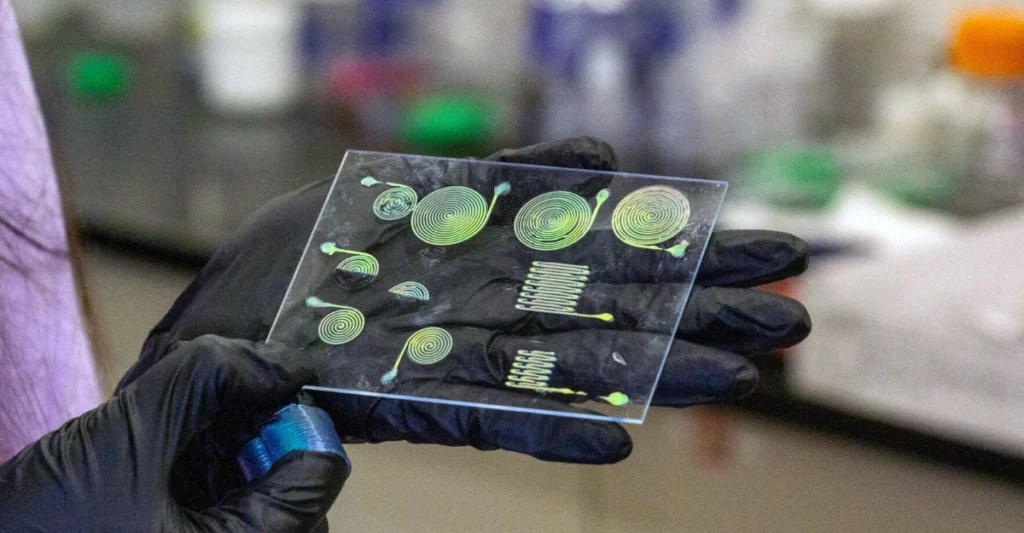

Led by Shu Yang, Professor of Materials Science and Engineering, and Ph. D. student Alicia Ng, introducing a new process named Coaxial Direct Ink Writing (DIW). This design combines a CLCE core with a transparent silicone shell, preserving the light manipulating capabilities of the material with the ability to create complex 3D designs. “Similar to the shell of a beetle, these materials are using structural color, not pigments,” says Yang, who notes potential applications in medical diagnostics, robotics and even art.

It has in the past been difficult to 3D print CLCEs because of the high viscosity of the material, which destroyed the twisted helix structures cause colours to change. Ng’s group fine-tuned the flow of the CLCE to achieve a good compromise between structural integrity and printability. “You have a silicone frame there to make the setup stable without sacrificing function,” she says.

Read more : New CNT Masterbatches Strengthen 3D Printing Materials

Possible applications range from adaptive displays, to stress-monitoring sensors, soft robotics, computer interfaces, and more. The researchers imagine such techniques being integrated into wearable tech that visually indicates muscle strain or environmental changes. Combining utilitarian and aesthetic function, the advance represents an important step toward the development of responsive, multifunctional smart materials.