Embry-Riddle leads US advancement in ceramic 3D printing technology with groundbreaking Lithoz installation for NASA-focused research.

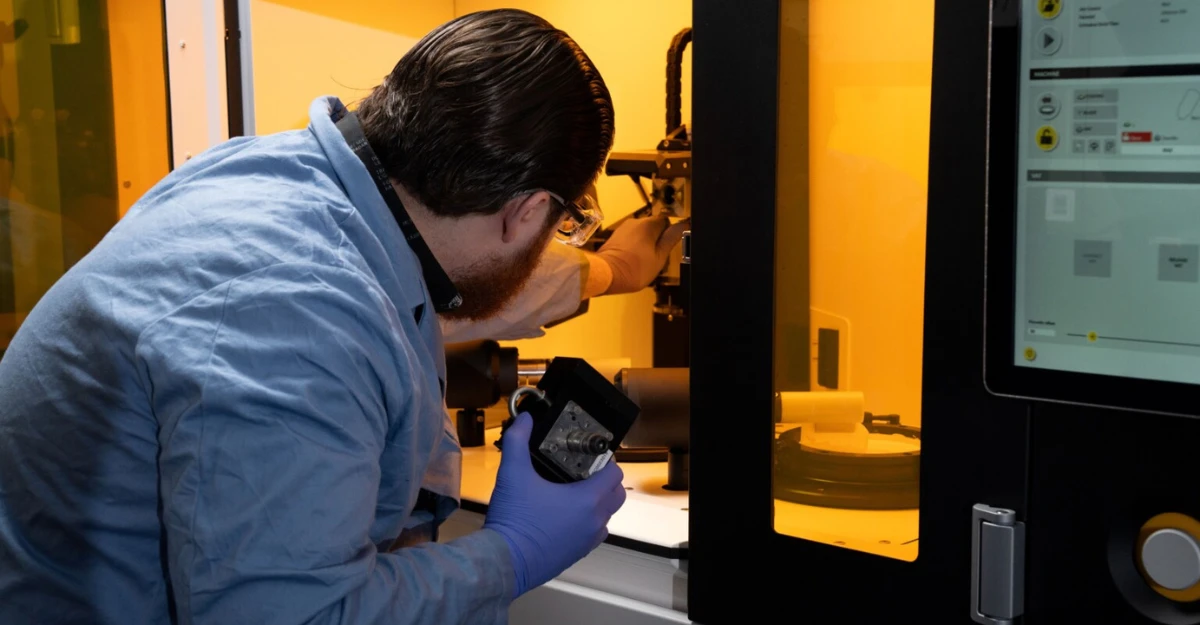

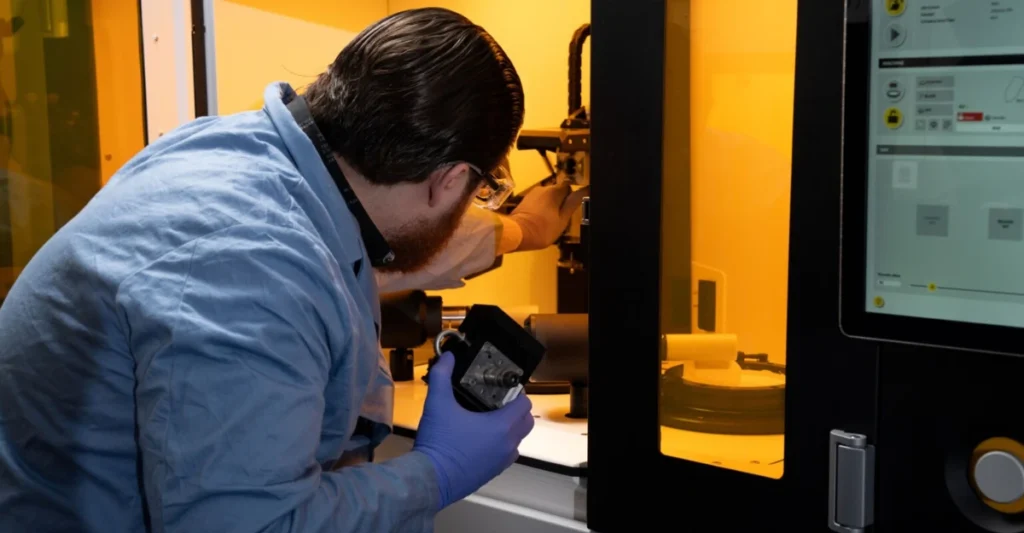

If you’re keeping tabs on the latest in aerospace manufacturing tech, here’s something that’ll catch your attention: Embry-Riddle Aeronautical University just made history by installing the first Lithoz CeraFab Multi 3D printing system in the United States.

This isn’t just any ordinary printer sitting in their Daytona Beach Campus. The CeraFab Multi 2M30 is a cutting-edge piece of kit that’s already making waves in NASA-related projects. What makes it special? Well, imagine being able to mix and match ceramics with either more ceramics or metals in a single print – that’s exactly what this machine brings to the table.

The university’s already putting this tech through its paces, and the results are pretty impressive. They’ve been cooking up bio-inspired patterns that could be a game-changer for lunar missions. These patterns, taking cues from nature’s own design handbook – specifically the lotus leaf – are aimed at tackling that pesky moon dust problem that’s been giving astronauts headaches since the Apollo days.

But that’s just the beginning. Dr. Seetha Raghavan, who’s leading the charge as Professor of Aerospace Engineering at Embry-Riddle, can barely contain her excitement about the printer’s capabilities. “We’re talking about manufacturing ceramics with incredible precision,” she explains, highlighting how this tech is fast-tracking their material design process.

Looking ahead, the university’s got big plans for their new toy. From developing tough-as-nails coatings for lunar exploration gear to crafting smart sensors for using space resources on-site, this machine is set to be at the heart of some seriously cool research initiatives.

For those keeping score, this installation isn’t just a win for Embry-Riddle – it’s a significant step forward for American aerospace research and manufacturing capabilities. And who knows? The next breakthrough in space exploration might just come from this very printer.