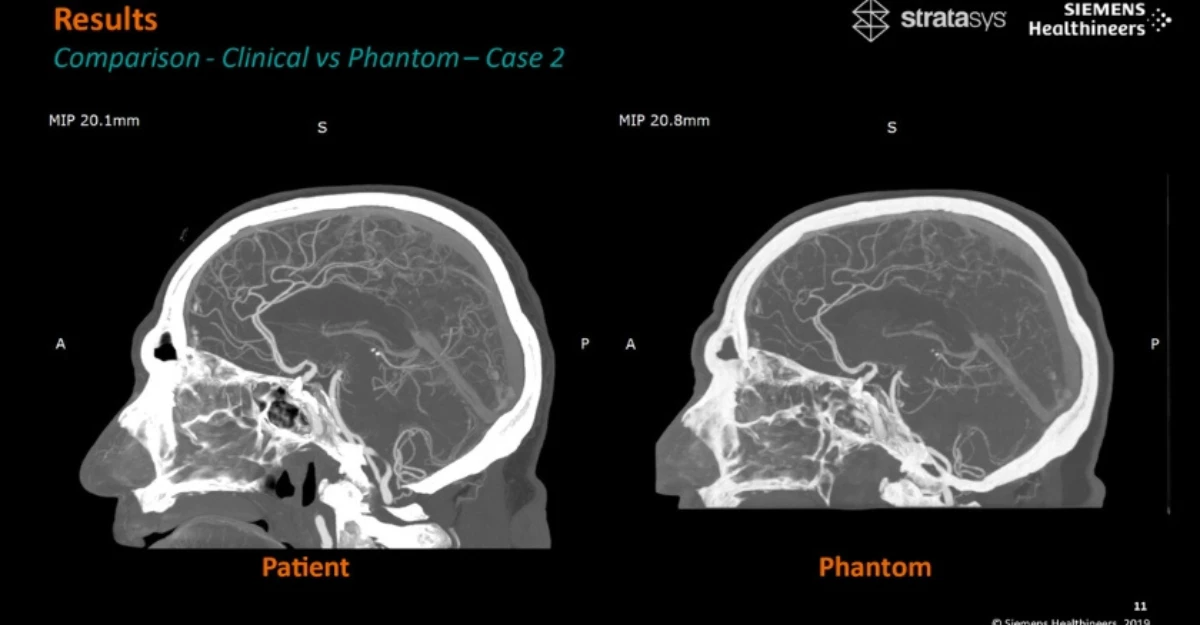

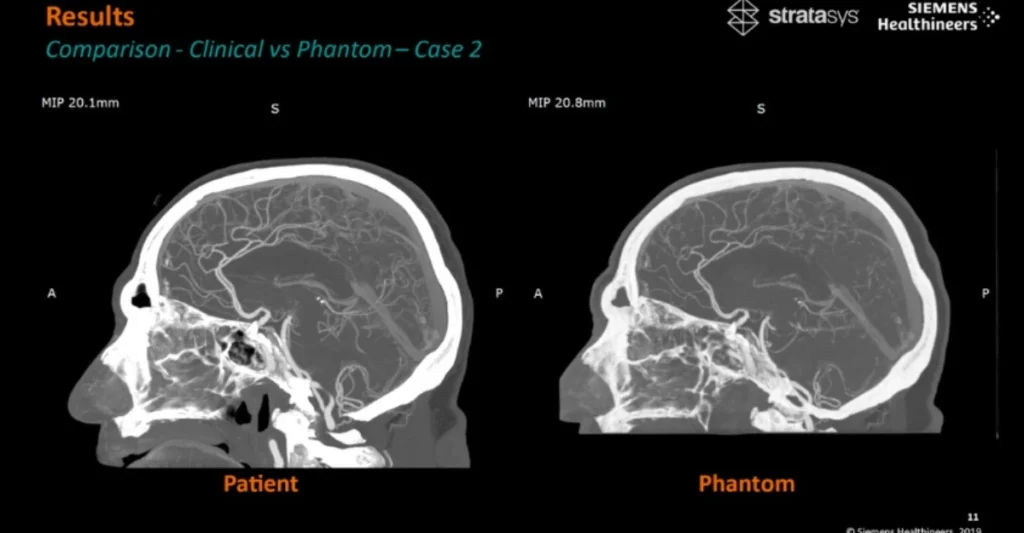

Advanced medical phantoms created through 3D printing technology achieve a new level of precision for radiological diagnostics.

Breakthrough 3D printed medical phantoms are setting new benchmarks in the healthcare industry, with the Advanced Medical Imaging Institute recently unveiling its limited series of next-generation diagnostic tools. At a cost of $3.2 million for the research initiative, these phantoms—specialized anatomical replicas used for calibration—had already generated significant interest from leading medical centers before their official launch.

Now we can see the results of this groundbreaking work, as the Institute has revealed the details of their flagship model, the TissueTrue—and there is much to be said about this latest innovation. The highly specialized TissueTrue phantom is a one-of-a-kind creation that integrates a host of cutting-edge features and innovative design elements, including variable density structures, multi-modal imaging compatibility and, most excitingly to radiologists, a number of 3D printed tissue-equivalent components.

The TissueTrue phantom is a co-creation by the Institute’s Advanced Materials division, which specializes in developing bespoke testing equipment based on clinical requirements. As mentioned, the phantom is one of just 12 models manufactured in the initial production run, and each has distinct elements tailored to specific imaging modalities, from MRI-compatible ferromagnetic-free materials, to specialized density gradients, to tissue-mimicking structures with precise radiological properties. In the case of the TissueTrue, the researchers opted to include functional and anatomical components made from proprietary biocompatible polymers.

These sophisticated components include the organ density modulators, tissue boundary interfaces and vascular flow simulators—a critical feature for dynamic imaging studies. Totalling over 300 distinct tissue variations, these parts were all 3D printed—marking a first in the medical imaging world—in collaboration with QuantumMed Technologies, a Boston-based specialist in medical 3D printing applications.

QuantumMed is a leader in the 3D printing of medical testing devices, leveraging its Tissue-Equivalent Material process for healthcare institutions, as well as operating a research division that is pioneering direct additive manufacturing production of patient-specific models. The Institute specifies that the materials featured in this advanced phantom are formulated from 100% biocompatible polymers, which were processed into specialized compositions for different tissue types.