MIT researchers develop 3D printing method for multidirectional artificial muscles mimicking the human iris.

MIT engineers have created artificial muscle tissue that can contract in multiple directions using a new 3D printing technique, according to research published in Biomaterials Science.

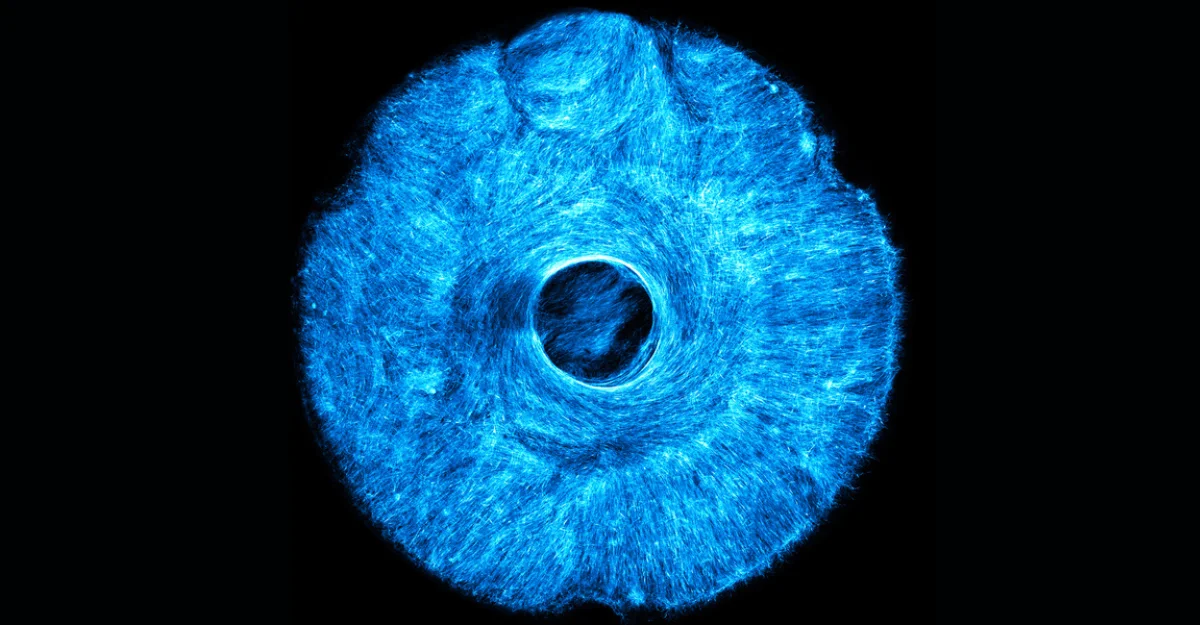

The breakthrough enables the engineered muscles to flex both concentrically and radially, similar to the human iris, overcoming limitations of traditional lab-grown muscle fibers that only move in a single direction.

The technique uses a 3D printed “stamp” with microscopic grooves as narrow as a single cell. When pressed into a hydrogel and seeded with genetically engineered muscle cells, the grooves guide muscle fiber orientation.

“With the iris design, we believe we have demonstrated the first skeletal muscle-powered robot that generates force in more than one direction,” said Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering at MIT.

The researchers used skeletal muscle cells instead of the smooth muscle found in the human iris to demonstrate their method’s versatility. When exposed to light, the artificial muscle contracts in a multidirectional fashion.

Beyond robotics, this stamping technique could enable engineering complex biological tissues like neurons and cardiac muscle. The stamp can be printed on standard desktop 3D printers, making the technology highly accessible.

The study received funding from the US Office of Naval Research, Army Research Office, National Science Foundation and National Institutes of Health.