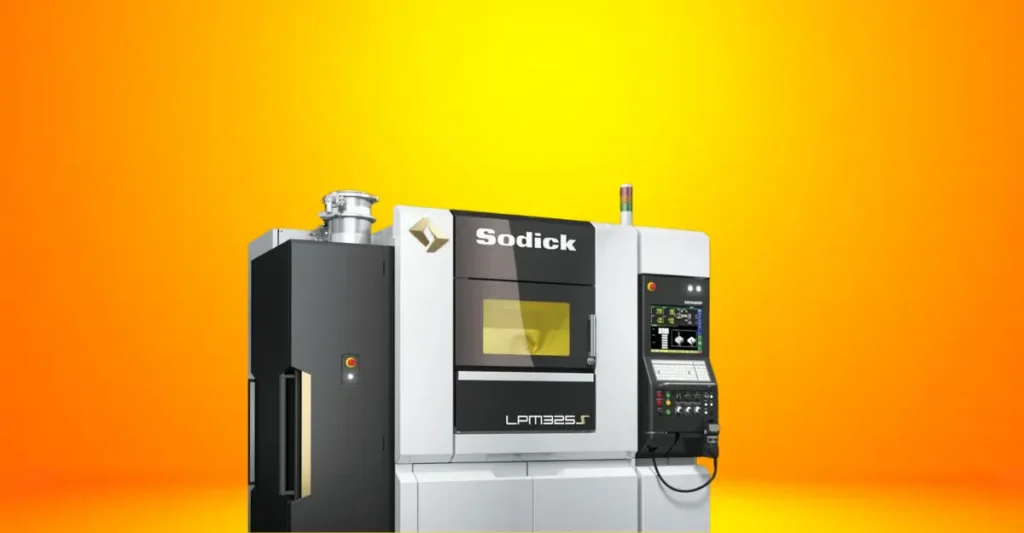

Japanese firm Sodick boosts its laser-based 3D printing expertise by securing a majority stake in Italy’s Prima Additive, aiming to drive advancements in high-precision metal additive manufacturing.

In a move designed to further its development of laser-based 3D printing, Japanese electric discharge machine manufacturer Sodick Co. has signed an agreement to acquire a majority stake in Italian metal additive manufacturing specialist Prima Additive. This comes after the company’s 9.5% investment in 2024 Sodick in the early part of this year, and is set to be completed later in the months to come.

This acquisition solidifies the strategic vision between the two companies for laser-based additive manufacturing. One of the main guides of the Collaboration is to accelerate the R&D of high-precision metallic 3D printing technology. The Italy-based prima Additive will operate independently as a subsidiary of Sodick under the guidance of CEO Paolo Calefati, bringing significant expertise in advanced laser manufacturing to support Sodick’s expansion efforts.

Driving Innovation in a Growing Market :

Just the global metal 3D printing market has projected growth of 24% CAGR for the next decade. This joint venture gives Sodick and Prima Additive access to the growing high-tech market for laser-based additive manufacturing systems across multiple industry verticals, including aerospace, automotive and medical devices.

Sodick first dipped its toes in the metal 3D printing pool in 2014, but it has been mainly aimed at the mold making sector, where the process has improved by implementing 3D-printed cooling channels. The company has primarily focused on the Japanese market, utilizing its existing sales network. But, as the automotive industry adopts gigacasting, a way of making large structural pieces in bulk, there’s been a demand for advanced additive manufacturing solutions.

Prima Additive’s Technological Edge :

Founded in 2018, Prima Additive has released a range of metal 3D printers, including both laser powder bed fusion and directed energy deposition systems. The company will also engage with help European research initiatives where it has been involved in various projects addressing automation, digital transformation, and advanced manufacturing systems. The company primarily addresses aerospace, marine, energy, and jewelry markets with its diverse product offering.

With the government in Japan advocating for domestic 3D printing of advanced multi-material components, Prima Additive’s technology is likely to be critical in broadening Sodick’s access to this space.

The Rise of Multi-Laser Technology :

Rapid developments in multi-laser systems, for example, will help speed and efficiency in the metal 3D printing sector. Industry analysts have referred to this trend as the “laser wars,” as manufacturers add more and more lasers into their machines to maintain a competitive advantage.

Displaying two major innovations were China-based Farsoon at TCT Asia 2025: a laser powder bed fusion system called the FS1521M-U, featuring 32 × 500W fiber lasers and a large build volume, and Beam Shaping Technology to optimize laser spot profiles for better part quality. These advances are signs of the industry’s drive for speedy, more affordable mass production.

Strategic Synergies for Future Growth :

The collaboration of Sodick and Prima Additive blends Sodick’s precision-manufacturing expertise with Prima Additive’s laser technologies that drive productivity. This collaboration will lead to breakthroughs in the whole new era of additive manufacturing that fits the increasing need for high-performance laser-based 3D printing solutions globally.

As the deal draw closer to completion, those in the industry speculate on how these developments might impact the landscape of metal additive manufacturing and reassert Sodick’s standing as a significant force in the field.