Stanford researchers develop r2rCLIP, enabling mass production of complex microscale particles at unprecedented speeds.

In an astonishing development that could transform how manufacturing is conducted at the microscale, researchers from Stanford University have developed a new technique for high-speed 3D printing that can create up to a million finely detailed particles every day. The modification made to continuous liquid interface production CLIP technology done by the Stanford researchers has attempted to solve ‘scalable fabrication’ issues in multiple domains such as pharmaceuticals, medicine, and microelectronics.

The new method, roll-to-roll CLIP (r2rCLIP), builds on previously established Stanford pogoed university’s ‘continuous liquid interface production (CLIP)’ technology introduced in 2015. The new technology allows construction of further customizable microscopic structures smaller than the human hair, achieving precision through speed.

A Leap from Prototypes to Mass Production

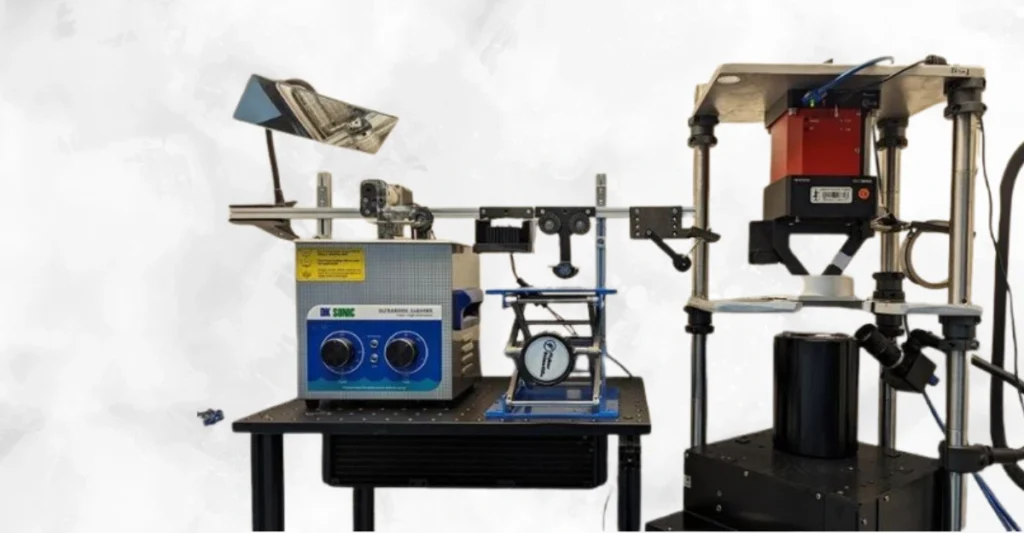

Traditional microscale 3D printing has been hampered by slow, labor-intensive processes. Each batch of particles required manual post-processing, limiting output to mere hundreds per day. The r2rCLIP system revolutionizes this workflow by integrating an assembly line approach. A tensioned film moves through stages of printing, washing, curing, and particle removal—all automated. This “roll-to-roll” design allows hundreds of particles to be printed simultaneously, slashing production timelines and achieving rates of 1 million particles daily.

“We’re navigating a precise balance between speed and resolution,” said Jason Kronenfeld, lead author and Ph.D. candidate in the lab of Joseph DeSimone, a Stanford professor and co-inventor of CLIP. “Our approach preserves fabrication pace while meeting the high-resolution demands essential for applications like drug delivery or microelectronics.”

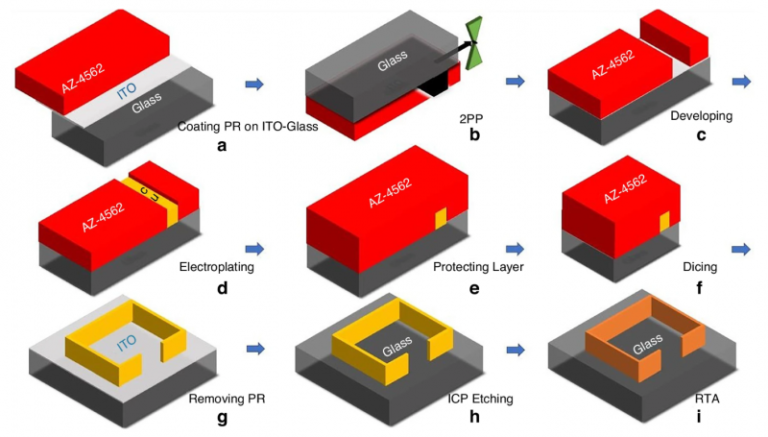

How r2rCLIP Works

The method uses oxygen permeable windows which project UV light to create a UV “dead zone” where the resin does not stick during the curing period, allowing delicate structures to be printed without damage. The light patterns, resin properties, and film movement can be synchronized for maximum efficiency.

“Using light to fabricate objects without molds opens a new horizon in the particle world,” said DeSimone, emphasizing the translational potential of the technology. “Scalability is key. We’re moving past prototypes to tools that enable industrial production.”

Bridging Macroscopic and Nanoscale Gaps

While nanoscale 3D printing exists, it remains slow. Macroscopic printing, used for products like shoes and dental devices, dominates mass manufacturing. r2rCLIP targets the critical middle ground—microscale particles with complex geometries—that underpin emerging technologies.

Applications span multiple fields:

- Medicine: Customized drug capsules for targeted delivery.

- Electronics: Microcomponents for compact devices.

- Manufacturing: Abrasives for precision engineering.

- Microfluidics: Lab-on-a-chip diagnostic tools.

“You don’t buy stuff you can’t make,” DeSimone noted, underscoring the lab’s focus on scalable solutions. “This isn’t just a research novelty. It’s a tool for industries of the future.”

Industry Implications and Adoption

The team envisions widespread adoption by academia and industry. Pharmaceutical companies, for instance, could accelerate drug development by testing millions of particle designs for optimal delivery. Electronics manufacturers might streamline prototyping of micro-sensors or circuits.

Kronenfeld highlighted the method’s adaptability: “Experts agree particle production must hit specific volumes for real-world impact. r2rCLIP bridges the lab-to-factory gap.”

Challenges and Future Directions

Tradeoffs remain. While r2rCLIP excels at microscale resolution, nanoscale printing still holds the edge for smaller features. However, the team believes their approach strikes the optimal compromise for commercial viability.

DeSimone sees the field evolving rapidly: “The conversation is shifting from how to print to what we can create. This is just the start.”

Read more : Alquist 3D Expands Housing with 3D Printed Concrete

Conclusion

Stanford’s r2rCLIP marks a paradigm shift in microscale manufacturing. By merging automation with precision, the method unlocks possibilities once deemed impractical. As industries embrace this technology, its impact on healthcare, electronics, and beyond could rival that of macroscopic 3D printing—proving that even the smallest innovations can drive monumental change.