Royal3D introduces the sustainable, modular ShearWater Aquatic Drone, designed for maritime tasks using advanced 3D printing and AI.

Royal3D Launches ShearWater Drone for Maritime Use

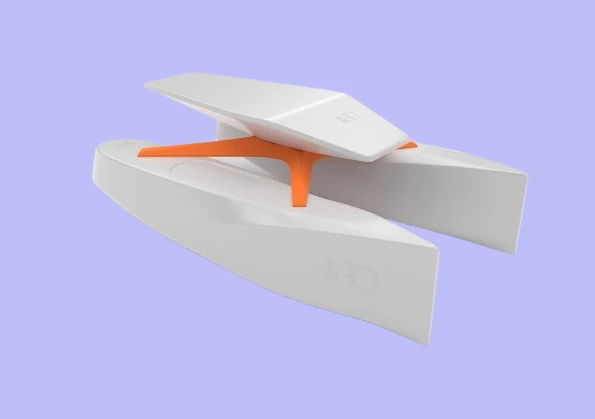

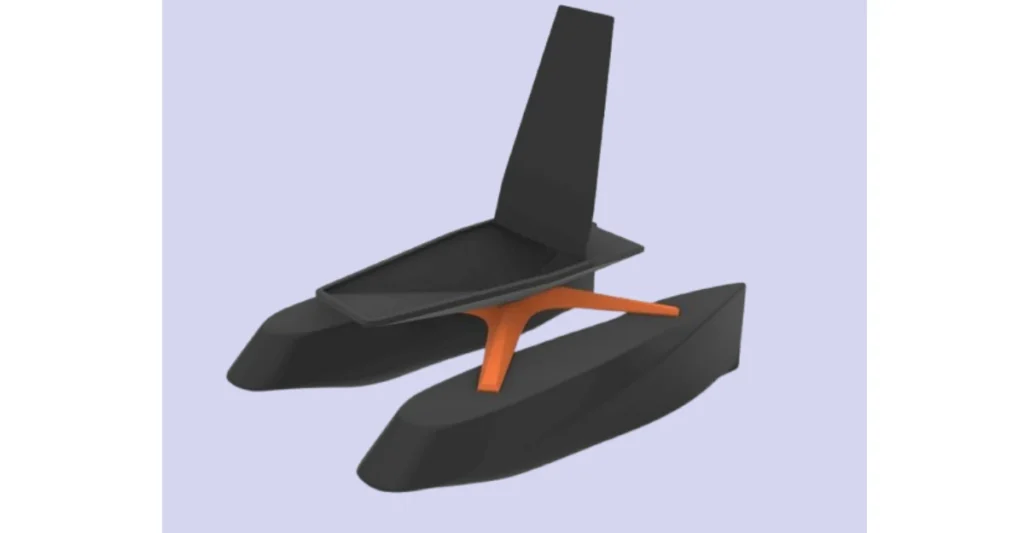

The ShearWater Aquatic Drone is the new maritime technology breakthrough from Dutch 3D printing innovator Royal3D. Targeted for maintenance, surveillance, and heavy-duty activities, the drone uses large-format additive manufacturing (LFAM) and sustainable materials to tackle issues in rugged marine environments.

Sustainable Design Meets Maritime Durability

The first drone built with all recycled and recyclable thermoplastic polymers and high-performance PETG fiber-reinforced materials, the ShearWater flies sustainably without compromising the performance. Its lightweight, waterproof design lends an element of rigidity and impact resistance, making it suitable for harsh environments like port inspections or offshore missions. A proprietary 3D printing process with InfraRed cameras for optimal layer adhesion assures structural continuity.

“Our expertise lies in adapting advanced 3D printing for industries where durability is non-negotiable,” said Fulko Roos, Founder of Royal3D and maritime logistics firm Royal Roos. “The ShearWater’s modular design allows companies to customize it for specific tasks, boosting both safety and productivity.”

AI and EU-Backed Innovation

The project, partly financed through the EU Crossroads initiative, builds in AI tools for maritime safety and also operational performance optimization via ShearWater. This allows for real-time data collection during inspections, improving decision-making for wildlife monitoring, Ship maintenance etc. Building on the trend of integrating AM with digital twin systems–which Sembcorp Marine first explored in a 2017 partnership with DNV GL to deploy drones for ship survey–the drone development represents a collective industry push, Huo said.

Event Showcase and Industry Legacy

At a free World Boating Day event, attendees will be able to see 3D printing in action as Royal3D showcases the ShearWater demonstrating its capabilities in Rotterdam on May 24th. This event highlights the company’s dedication to sustainable innovation and industry collaboration.

Royal3D also uses some of the largest 3D printers in continental Europe and, with over a decade’s worth of experience in large-scale AM, produce durable parts for the industry, including transport carriages and structural components. The company has a deep background in urban design, but it chose to emphasize maritime applications for the demand for personalized, environmentally-friendly solutions.

Maritime Drone Evolution

The ShearWater joins a lineage of 3D-printed drones reshaping maritime operations. In 2016, the British Royal Navy deployed the laser-sintered SULSA UAV from the HMS Protector for Antarctic ice patrols, proving the viability of 3D-printed drones in extreme conditions. Similarly, Sembcorp Marine’s drone-assisted inspections at Singapore’s Tuas Boulevard Yard showcased how digital twins and AM could streamline shipyard workflows.

Royal3D’s latest offering builds on these advancements, emphasizing material efficiency and scalability. By utilizing recycled polymers and modular components, the ShearWater reduces waste while offering flexibility for diverse missions—from underwater maintenance to coastal surveillance.

Read more : LulzBot Unveils TAZ 8 3D Printer With Larger Build and Better Precision

Future Focus

With its maritime industries in need of replacement ships that also meet environmental regulations, Royal3D hopes to lead the way in high-performance carbon-neutral solutions. It will broaden design capabilities and innovations in materials to ensure its drones meet future requirements in the sector.

According to Roos, “We are looking to redefine the limits of 3D printing in heavy-duty settings.” “From the ShearWater and forward,”

The ShearWater Aquatic Drone bridges the gap between the latest in technological advancement and a drive towards sustainability, heralding a new age of maritime operation, one where sustainability and efficiency sail hand in hand.