Aimen Technology Centre creates dual-system cryogenic tank demonstrator using large-format 3D printing technology for sustainable aviation applications.

The Aimen Technology Centre has achieved the development of a cryogenic tank demonstrator by means of 3D printing technologies for the OVERLEAF project The development represents one o the most relevant milestones in the trajectory of green solutions for aviation.

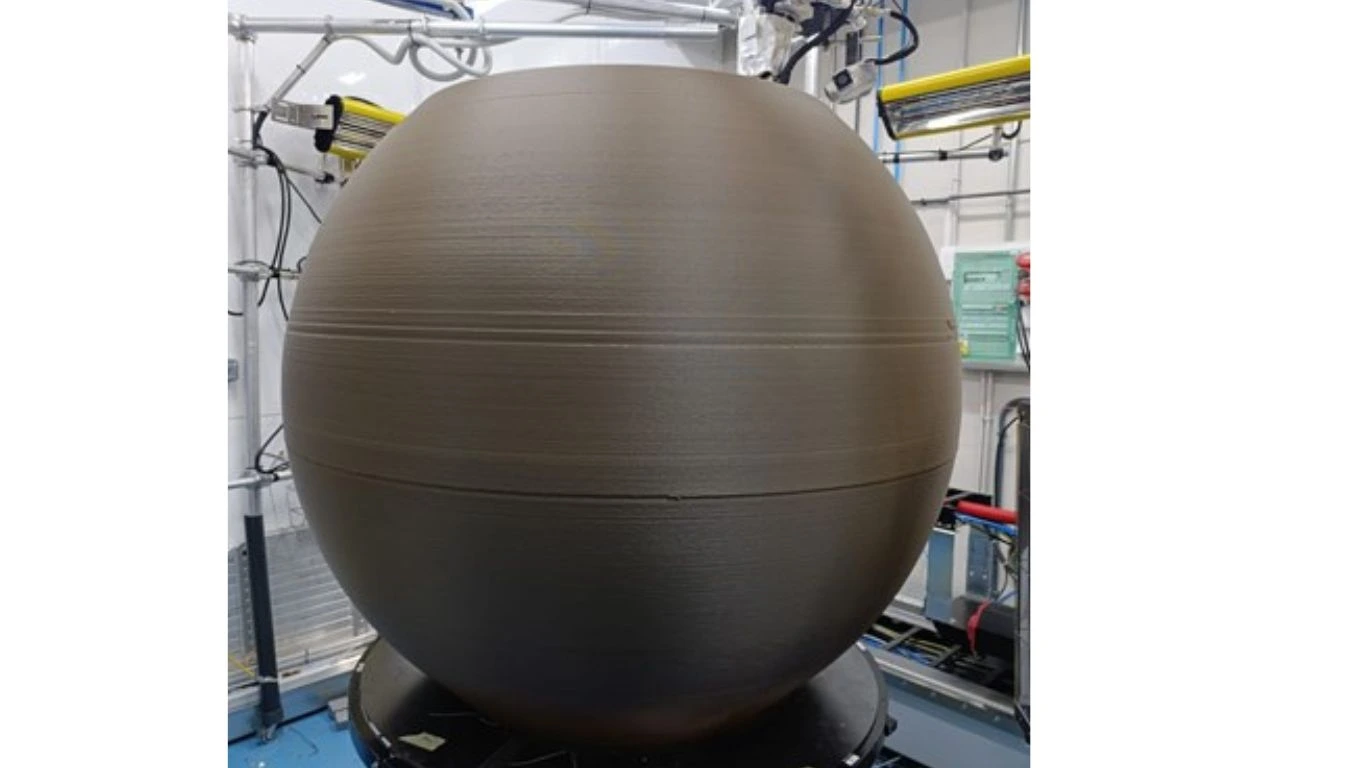

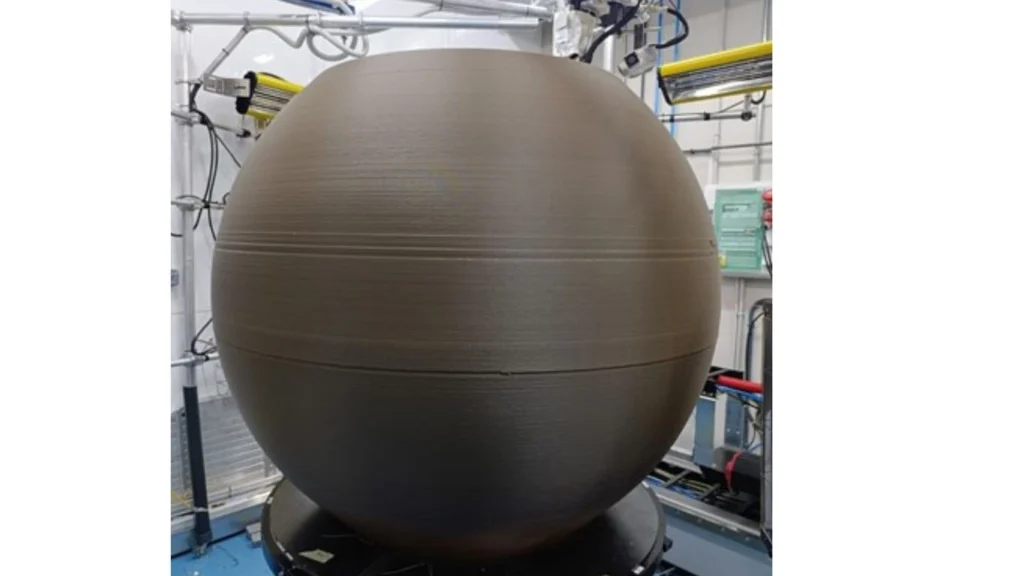

The LH2 tank, with a capacity for LH2 storage at temperatures below -250°C, has a dual system structure for future aircraft application. The design house on things such as an inner thermoplastic tank with extreme low temperatures necessary for liquid hydrogen storage, while an outer carbon fiber structure lends strength and safety.

“This is a technological solution that will mark a before and after in the manufacturing of components for sustainable aviation,” said Pablo Romero, team leader of the Additive Manufacturing of Composites R&D group and OVERLEAF project coordinator at Aimen.

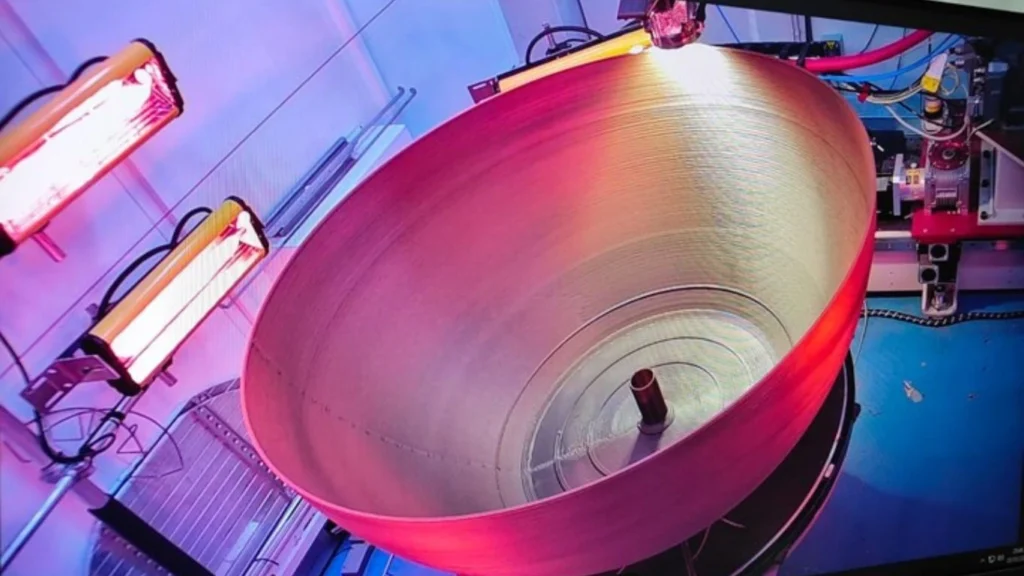

The Spanish technology center utilized high-precision, large-format additive manufacturing to produce the 1.5-meter-diameter inner tank. The manufacturing process required more than 100 uninterrupted hours of printing in a specialized robotic cell equipped with 3D printing systems and infrared heating technology to ensure proper layer adhesion. Real-time monitoring using thermal cameras was employed throughout the process.

Aimen collaborated with French center Canoe to develop a new sustainable material for the project. The bio-based thermoplastic reinforced with natural fibers enables the production of strong, lightweight and environmentally friendly structures.

“This project demonstrates how technology can respond to the major challenges of decarbonization. Investing in hydrogen as an energy vector also means transforming the systems that make it viable, and Aimen has a lot to contribute to this,” added Xabier Pérez, researcher and head of the tank’s additive manufacturing activities.

Read more : UW Team Creates Stronger Biodegradable 3D Printing Materials

The OVERLEAF project, led by Spanish aeronautics company Aciturri, aims to develop storage solutions for liquid hydrogen as part of broader efforts to reduce carbon emissions in the aviation industry.