A Muskoka company leverages 3D concrete printing to tackle Canada’s housing crisis with faster, cheaper, and eco-friendly home construction.

Muskoka Company Pioneers 3D-Printed Homes to Tackle Housing Affordability Crisis :

Linda Reisman, CEO of 3D Concrete Printing Muskoka (3DCP Muskoka), is on a mission to revolutionize home construction in Canada. Her solution? A game-changing invention that may alter the course of affordable housing is a robotic 3D printer that can construct the walls of a house covering 2000 square foot area in 72 hours.

Reisman’s inspiration stemmed from firsthand experience. After purchasing property during the COVID-19 pandemic, rising costs forced her to shelve plans to build a traditional home. Simultaneously, her volunteer work with low-income families in Muskoka highlighted the dire need for economical housing solutions. “If constructing homes by traditional methods is beyond most people’s means, why not print them?” she recalled thinking.

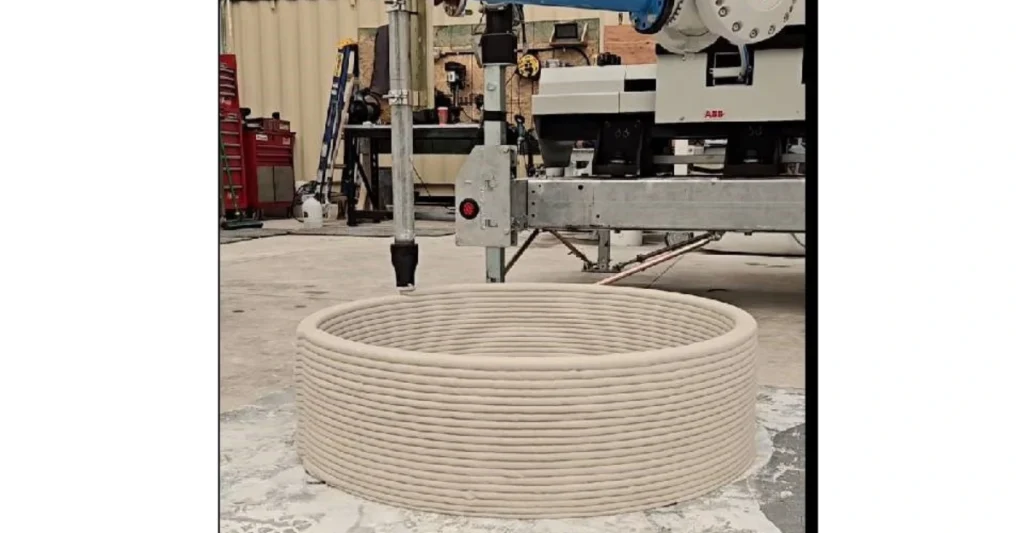

Founded in 2020 with her partner and Chief Technology Officer Zohar Klevan, 3DCP Muskoka aims to address these challenges using a mobile robotic arm mounted on a travel trailer. The 14,000-pound printer uses a specialized concrete mixture—enhanced with polymers, fibers, and other additives—to layer walls directly onto a site’s topography, even adapting to rocky terrain without requiring blasting.

“The sky’s the limit with this technology,” Reisman said. “We’re not reinventing the wheel. Concrete has been used for centuries—we’re just applying it innovatively.”

How It Works :

The process begins with a digital design programmed into the robotic arm, which extrudes the concrete mixture in precise layers. Electrical and plumbing systems are integrated as the walls rise, minimizing waste and labor. Unlike traditional builds, which can take months, 3DCP Muskoka’s method slashes construction timelines and reduces costs by up to 30%, according to industry estimates.

The company’s printer is fully mobile, enabling Reisman’s team to deploy across Ontario. “We’ll go to North Bay, Sudbury, Timmins—anywhere there’s a project,” she emphasized.

Overcoming Barriers :

Despite its potential, 3D concrete printing remains a nascent technology in Canada. Reisman notes that only six companies nationwide are exploring its viability, partly due to regulatory hurdles. Building codes, designed for conventional methods, require adaptation to accommodate 3D-printed structures.

“It’s about collaboration,” Reisman explained.Dedicated specialists coordinate efforts with her team. As she expressed, “We collaborate with the engineers and architects so the designs are within safety limits.” SHe is working to increase awareness of this approach’s advantages in policy making and the general community: its efficiency, environmental friendliness, potential for rapid construction, and low cost.

Read more : Why Bambu Lab Dominating the 3D Printing Market in 2025?

Sustainable Vision :

Environmental impact is a cornerstone of 3DCP Muskoka’s ethos. The process generates significantly less waste than traditional construction and uses locally sourced materials where possible. Reisman aims to develop a proprietary concrete blend using regional resources, further reducing the carbon footprint.

“Eventually, we want to create our own raw materials from what’s available in the environment,” she said. “That’s the future of sustainable building.”

Expansion and Partnerships :

With a new print head arriving from the Netherlands—a leader in 3D concrete tech—Reisman anticipates rapid growth this spring. The company recently secured a Bracebridge facility to serve as a headquarters, R&D hub, and showroom. Here, developers and policymakers can witness live demonstrations, including a model home slated for printing this year.

3DCP Muskoka is also in talks with Indigenous communities and local developers to construct proof-of-concept homes. One project under discussion involves a partnership to build affordable housing in Gravenhurst, where Reisman hopes to eventually 3D-print her own home on 21 acres.

Challenges and Ambitions :

Funding remains a hurdle. To date, Reisman has self-financed the venture, delaying her personal homeownership goals. However, repayable government loans and growing interest from investors signal momentum.

Her ultimate vision? A community of 3D-printed homes in Muskoka, offering families a blend of affordability, durability, and design flexibility. “Seeing is believing,” she said. “Once people witness this technology in action, attitudes will shift.”

A New Era for Construction :

As housing prices soar across Canada, 3DCP Muskoka’s innovation arrives at a critical time. Not only does the approach solve the problem of cost, but it also complements the evolving shifts toward automated and environmentally friendly construction practices of the rest of the world.

“We do not consider ourselves builders but rather enablers,” Reisman emphasized. “Our partnership with the developers allows us to add efficiency, creativity, and sustainability into our projects.”

At the moment, her team is concentrating on elementary products such as furniture and planters as they build towards larger scale residential projects. Reisman’s faith in 3D printing’s promise is unwavering, especially with a robotic arm set to print a full-sized home this year.