ATO Technology debuts advanced ultrasonic atomization systems and modular metal powder production tools, enhancing sustainable in-house manufacturing capabilities.

ATO Showcases Next-Gen Metal Powder Innovations at RAPID + TCT 2025

In conjunction with its American distributor Additive Plus at Booth 3208, ATO Technology showcased their ULTRA FREQUENCY SYSTEM and new metal powder production equipment during RAPID + TCT 2025. These developments mark advancements for ATO Technologies. At the core, their goal is to transform efficiency, precision, and sustainability in decentralized metal powder manufacturing systems.

Advanced Ultrasonic Atomization for Precision Powders

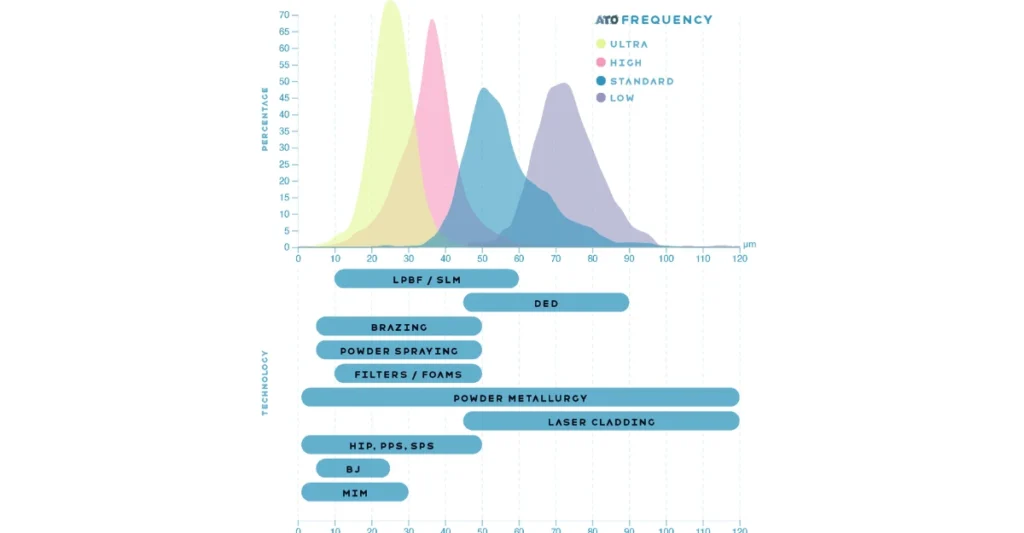

The ULTRA FREQUENCY SYSTEM announced recently is noted as the ‘**fourth generation’ ultrasonic atomizer’. It is a new device capable of fabricating fine metal powders with an average particle size of *25 µm* (with low deviation). It aims to achieve high precision in additive manufacturing and powder metallurgy, allowing extremely tight control over the parameters of the powder. This granularity of control is critical for the most advanced industries like aerospace and medical equipment fabrication.

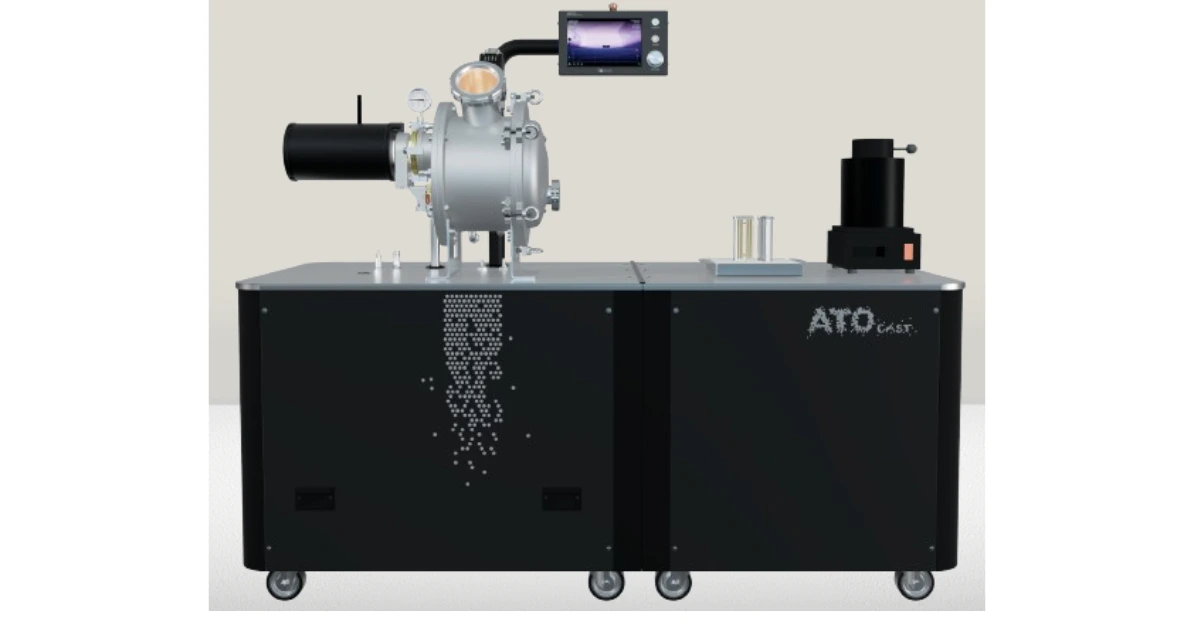

Accompanied with this, ATO also launched the latest version of ATO Cast induction vacuum casting furnace, now integrated with an oxygen sensor, pyrometer live camera monitoring, and a redesigned graphical interface. ATO Cast is rod feeding system compatible and supports alloy development, material recovery, and rod production, making it useful for R&D and industrial processes.

Modular Ecosystem for Closed-Loop Manufacturing

The new devices create a modular structure for the entire production cycle to utilize different inputs such as commercial rods, custom ingots, and even 3D printing scrap. This integrated method helps the manufacturer regain material by reducing waste and external sources of supply. Firms can produce both standard and custom alloys, which speeds up prototyping while reducing lead times, material costs, and resource consumption.

ATO highlights sustainability as the primary focus indicating that in-house powder production lessens the environmental footprint while increasing the reliability of the supply chain. This solution also caters to the global shift towards circular manufacturing because it enables the transformation of scrap into high-quality powders.

Industry Shift Toward Decentralized Production

ATO’s launches mirror broader industry movements toward localized, customizable production. For instance, SPEE3D’s cold spray systems for on-site part fabrication in extreme environments and Velo3D’s Sapphire XC 1MZ printer, optimized for high throughput and powder efficiency, underscore the demand for agile manufacturing solutions. ATO’s ultrasonic atomization technology and closed-loop workflows position the company at the forefront of this shift, enabling users to bypass traditional powder supply chains.

Read more : Nano Dimension Finalizes $179M Deal to Acquire Desktop Metal

Strategic Partnerships and Future Outlook

By collaborating with Additive Plus, ATO looks to grow its presence in North America by providing manufacturers with opportunities to innovate while keeping a tighter grip on material quality and costs. The firm’s emphasis on modular, scalable systems indicates greater concern for flexibility across various sectors, from automotive to energy.

Attending RAPID + TCT 2025, ATO will showcase innovations that mark a milestone in metal additive manufacturing—encompassing precision, sustainability, and supply chain self-sufficiency which are bound to redefine production frameworks.