Bambu Lab has finally delivered what 3D printing enthusiasts have been waiting for: a true all-in-one fabrication system that combines high-speed dual-nozzle printing with laser cutting and engraving capabilities. The new Bambu Lab H2D represents the company’s most ambitious offering yet, with a price tag that matches its premium feature set.

3D printing enthusiasts have been asking for more versatile machines ever since manufacturers began experimenting with hybrid systems several years ago. The Bambu Lab H2D answers this call with a sophisticated setup that doesn’t compromise on either printing or laser performance.

The Bambu Lab H2D is designed with both ease of use and advanced capabilities in mind: nothing requires complex calibration, and the whole system features automatic detection and configuration options. The robust aluminum and steel frame with glass panels serves as both enclosure and structural support, which the company claims provides exceptional stability during high-speed printing operations. We’ll cover more on the design details later in this review.

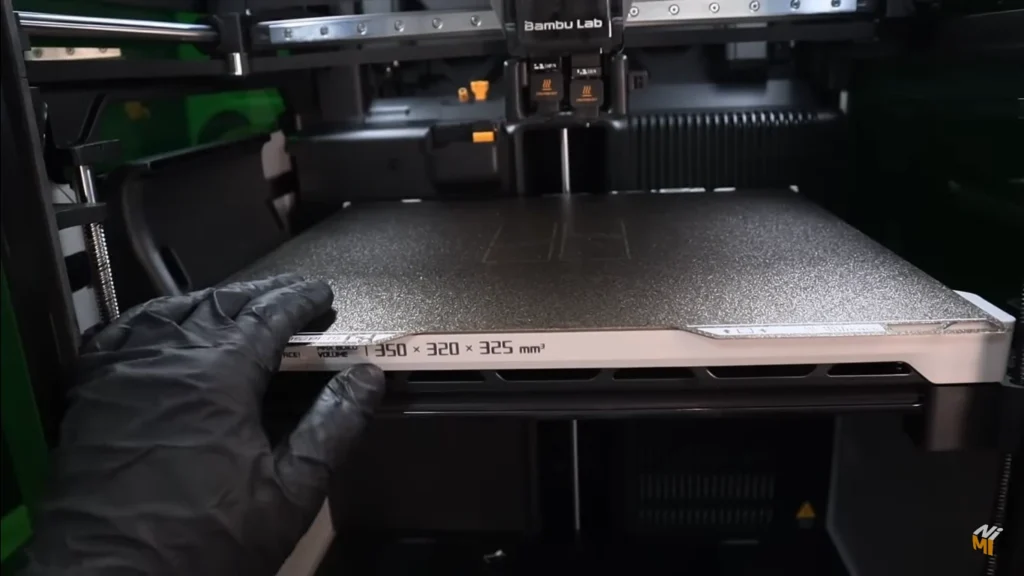

The H2D is not a replacement for Bambu’s existing machines like the X1C or P1P, and also offers an upscale option for makers who require multi-material printing and multi-function fabrication capabilities. This machine has a generous build volume of 350×320×325 mm³, features a heated chamber that can reach 65°C for printing engineering filaments, and includes an advanced filtration system for safe indoor operation. This means even high-temperature materials like ABS can be printed without filling your space with unpleasant odors.

The Bambu Lab H2D starts at $2,399 for the base model, with the full laser combo package reaching $4,399. You can save money by opting for the middle-ground AMS Combo at $2,699 if you need multi-material printing but not laser capabilities. The Bambu Lab H2D delivers on its promises and stands as one of the most capable consumer-level fabrication systems we’ve tested to date.

Key Specifications

| Specification | Detail |

|---|---|

| Price | $2,399 – $4,399 |

| Build Volume | 350×320×325 mm³ |

| Weight | 31 kg |

| Nozzle Temp | Up to 350°C |

| Chamber Temp | Up to 65°C |

| Bed Heating | 70°C in ~60 sec |

| Nozzle Type | Hardened Steel |

| Print Speed | Up to 600mm/s |

| Noise Level | Max 54 dB |

| Laser Options | 10W or 40W |

| Calibration | Auto (5μm res) |

| Connectivity | Wi-Fi, USB, LAN |

Design Overview

The Bambu Lab H2D sports a robust aluminum, steel, and glass construction that feels substantial from the moment you unbox it. Unlike some entry-level machines that feel flimsy, this 31 kg (68 pound) printer is built like a tank. The fully enclosed design includes a heated chamber that can reach up to 65°C, allowing for more consistent prints with technical materials that would warp in open-air printers.

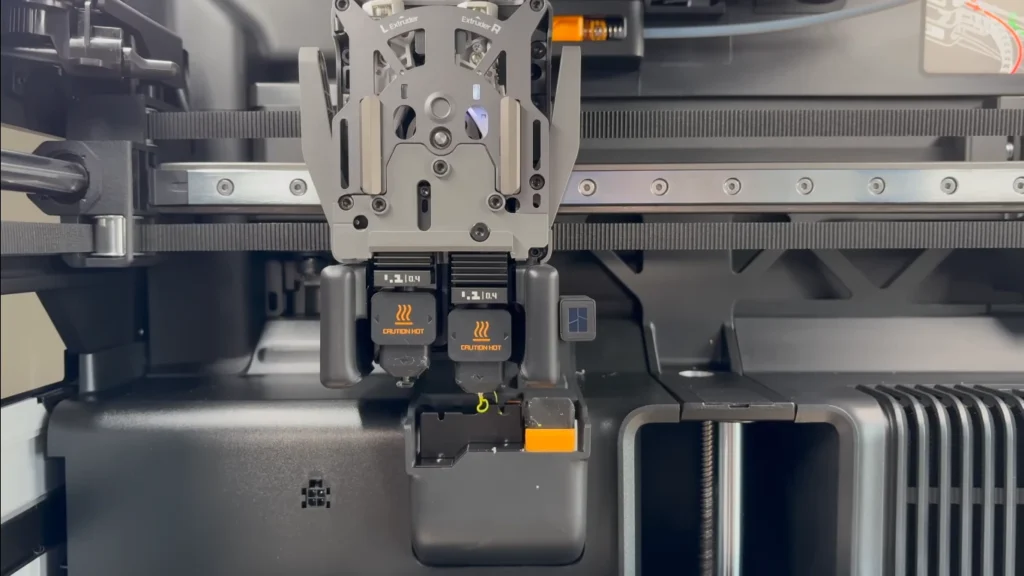

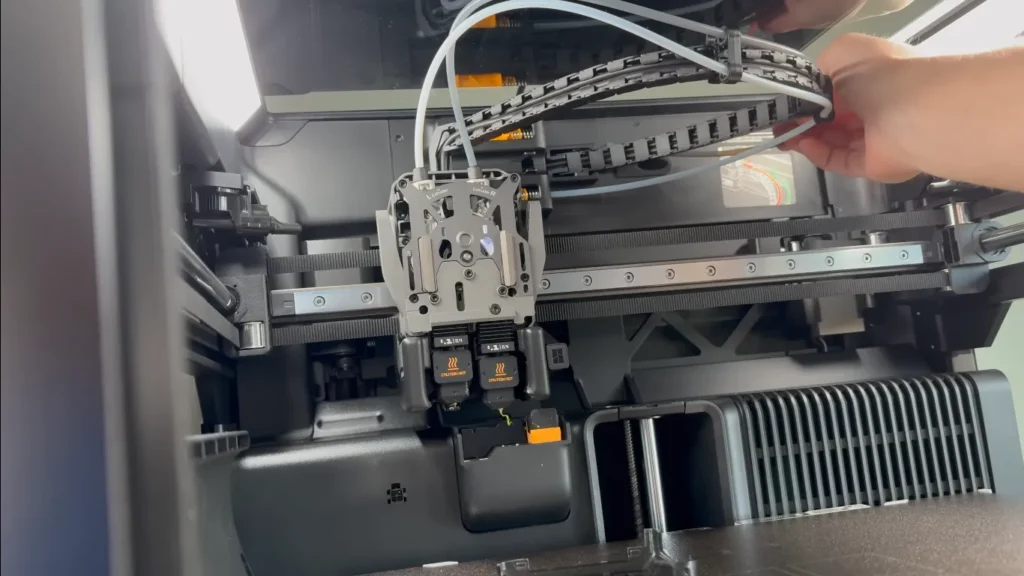

Where the Bambu Lab H2D really stands out is its dual-nozzle system. This isn’t just a printer with two identical nozzles it’s a sophisticated setup that allows true multi-material printing. Each nozzle is made from hardened steel, and can handle temperatures up to 350°C, allowing it to print with real exotic materials like carbon fiber filaments and high-temperature plastics that would destroy standard nozzles.

The build volume deserves special mention: the total printing area spans 350×320×325 mm³, though there’s a caveat. When using both nozzles, you’re limited to 300×320×325 mm³ for the primary nozzle. This is a necessary compromise given the offset between the two nozzles, but it’s still plenty of space for most projects. The textured PEI build plate provides excellent adhesion and comes standard with the printer.

For visibility and monitoring, Bambu Lab has included two cameras in the system one for time-lapse recording and another focused on the nozzles. While helpful for remote monitoring, I found the side camera positioning a bit concerning from a privacy standpoint, as it was aimed directly at my computer screen. I ended up covering this camera when not in use, though the nozzle camera proved genuinely useful for catching issues before they become print failures.

What’s in the Box

The Bambu Lab H2D comes in several configurations, and what you get depends on which package you choose. The base H2D ($2,399) includes the printer itself, a textured PEI build plate, spool holder, accessory box, and safety key. If you opt for the AMS Combo ($2,699), you’ll also get the AMS 2 Pro automatic material system, which allows for multi-filament printing without manual intervention.

Where things get really interesting is with the Laser Full Combo packages. These come with either a 10W ($3,499) or 40W ($4,399) laser module, along with a cutting module with pen holder, laser platform, cutting platform, ventilation pipe, emergency stop button, and materials for testing the laser and cutting capabilities. The Laser Edition also includes special safety windows to protect your eyes during laser operation.

The accessory box comes with the standard set of tools for maintenance and settings: Allen wrenches, scraper, tweezers, nozzle cleaning tools and lubricant. Bambu Lab also includes a small amount of starter filament, though serious users will want to stock up on their preferred materials.

Assembly and Setup

Unlike many DIY 3D printer kits that require hours of assembly and calibration, the Bambu Lab H2D arrives mostly assembled. The setup process involves removing packaging materials, installing the build plate, connecting the spool holder, and plugging in power. If you purchased the AMS Combo, there’s some additional setup for connecting the filament handling system, but the process is straightforward.

The AMS 2 Pro is a significant improvement over the original AMS. It’s slightly wider for better filament fitting, features a polycarbonate lid for improved humidity control, and offers one-handed PTFE tube removal. Perhaps most impressively, it can automatically vent humid air during drying cycles and seal itself when complete no more manual plugs to fiddle with.

One of the most surprising aspects of the setup is what you don’t need to do. The Bambu Lab H2D features full auto-calibration, eliminating the tedious manual leveling process that plagues many printers. Just press a button, and the machine handles the details, using optical motion calibration with 5μm resolution to ensure precise positioning.

Bed Leveling

Speaking of bed leveling, the Bambu Lab H2D makes this traditionally frustrating process nearly automatic. The printer uses a sophisticated sensor array to detect the build plate’s position and automatically compensates for any slight variations. In testing, the bed heating performance was exceptional reaching 70°C in just over a minute and 90°C in under two minutes. This rapid heating doesn’t seem to cause any warping issues, as the first layers consistently adhere perfectly.

Thermal imaging confirmed that the heat distribution across the bed is remarkably even, which contributes to consistent print quality. The textured PEI surface works great for adhesion with most materials, but you’ll of course want to tune your settings depending on what specific filament you’re using, as with any printer.

Loading Filament

Filament loading is where the Bambu Lab H2D truly shines, especially if you’ve opted for the AMS 2 Pro system. Without the AMS, loading is still straightforward through the printer’s interface, but the automatic system takes convenience to another level. You simply place your spools in the AMS bays, feed the filament into the designated tubes, and let the system handle the rest.

The Bambu Lab H2D features what Bambu calls Material CodeSync the ability to automatically adjust print settings based on the material you’re using. This works best with Bambu’s official filaments, which contain embedded information, but the system can also calibrate third-party filaments and remember those settings for future use. This calibration process significantly reduces waste and eliminates the guesswork of getting perfect extrusion.

For those interested in exotic materials, the H2D’s all-metal hotend and hardened steel components mean you can print with abrasive filaments like carbon fiber or glass-filled nylon without worrying about premature wear. In testing, even ultra-flexible TPU with a 9A hardness rating printed successfully, though getting it through the spool guide required some patience.

File Setup & Software

Bambu Lab’s proprietary slicer, Bambu Studio, is the recommended software for the H2D. Built upon the open-source PrusaSlicer, it’s been significantly adapted to leverage the Bambu Lab H2D’s unique capabilities, especially its dual-nozzle system and material handling.

The slicer includes profiles for a wide range of materials and quality settings, making it easy to get started. For dual-material prints, the software handles the complex task of coordinating the two nozzles, including purge operations to prevent color contamination. While there is some waste material generated during nozzle switches, it’s significantly less than on previous multi-material systems.

One of the software’s standout features is its ability to optimize multi-color prints. If you’re printing with the AMS system, Bambu Studio can arrange color changes to minimize filament swaps. In one test, this saved approximately 72-73 filament changes compared to a naive approach, resulting in faster prints and less material waste.

For those interested in the laser cutting and engraving features, the software includes dedicated modes for these operations, with settings for different materials and cutting depths. The integration is so smooth that you can move from printing to laser operations without leaving the software environment.

Starting a Print

Once your file is prepared and sent to the printer, the Bambu Lab H2D takes over with impressive automation. The print sequence begins with bed heating (which, as mentioned, is remarkably fast), followed by a nozzle cleaning routine. If using two materials, the printer will load both filaments and perform calibration if needed.

The first layer goes down with precision, and the printer’s CoreXY design allows for impressive speed without sacrificing quality. Bambu Lab claims speeds up to 600mm/s, and while real-world speeds are typically lower depending on the complexity of your print, this is still among the fastest consumer printers on the market.

The enclosed chamber with its filtration system makes printing with odorous materials like ABS much more pleasant. The printer features an automatic ventilation system that handles air differently based on your material for low-temperature materials, it vents directly outside, while for high-temperature materials, it routes air through a Bento box-style filter before exhausting. The flaps close automatically when printing is complete, preventing drafts and keeping dust out of the chamber.

Practical Usability Tips

The Bambu Lab H2D offers impressive capabilities, but getting the most out of this premium machine requires some practical know-how. After extensive testing, I’ve discovered several tips that can enhance your experience and avoid potential frustrations.

When working with dual materials, try to limit your prints to just two materials whenever possible. While the Bambu Lab H2D can handle multiple material changes through the AMS system, the printer works fastest and generates the least waste when simply switching between two nozzles rather than swapping filaments on a single nozzle. In testing, this approach cut a basic print time in half compared to traditional filament-swapping methods.

The hotend swap system deserves special attention. Unlike previous Bambu printers that required disconnecting connectors with tweezers, the Bambu Lab H2D features a more streamlined approach. However, I found that using two hotends with different nozzle sizes simultaneously can cause issues. While it’s possible to override this limitation, my tests showed occasional problems during the first purge cycle. For best results, stick with identical nozzle sizes in both hotends.

For those working with flexible materials like ultra-soft TPU, be aware that feeding it through the spool guide can be challenging. In my tests with 9A TPU (an extremely flexible variety), I needed to perform a cold pull to remove previous filament completely before loading the TPU. Once loaded, though, the printer handled it remarkably well.

Also Read: Prusa CORE One Review: The Fast, Precise, and Future-Proof 3D Printer

If you encounter issues with purge material falling into the build chamber (particularly with PETG, which can be sticky), a single application of Slices plastic repellent solves the problem. This simple step saves significant cleanup time and prevents potential print failures.

When configuring multi-material prints, especially those combining different material types, pay attention to compatibility. In testing, TPU adhered well to PETG, creating strong bonds between flexible and rigid sections. However, TPU and PLA didn’t bond as effectively. Testing small sample pieces before committing to a large multi-material print can save considerable time and material.

For those using the laser cutting features, proper ventilation is crucial. While the built-in ventilation system works well, connecting the external ventilation pipe to direct fumes outside your workspace is strongly recommended, especially for extended cutting sessions or materials that produce potentially harmful vapors.

The Bambu Lab H2D’s automatic calibration works excellently, but for even better results with different material brands, take advantage of the filament calibration memory feature. The printer can remember which filaments have already been calibrated, which not only saves time but also reduces waste from repeated calibration processes.

Finally, if privacy is a concern, consider the camera placement. The side camera can sometimes capture more of your workspace than intended. I found a simple removable cover for this camera was helpful when not actively monitoring prints, while still allowing access to the useful nozzle camera for catching potential issues.

Print Quality and Performance

After hundreds of hours of testing across multiple materials, the Bambu Lab H2D consistently delivers excellent results. Outside dimensions on printed parts were extremely accurate, with only slight undersizing of holes (around 0.15-0.2mm) and outside dimensions (0.6-0.7mm) well within acceptable limits for most applications.

The printer excels at multi-material prints, with the dual-nozzle system allowing for some truly impressive combinations. In testing, combining soft TPU with rigid PETG created functional parts with both flexible and rigid sections something that would require multiple prints and assembly on single-nozzle machines. The hotend switching is fast too, taking just 10-15 seconds compared to the roughly 2 minutes required for a filament swap.

One area where the Bambu Lab H2D particularly shines is in print surface quality. There are minimal visible layer artifacts, and layer alignment is consistently perfect. There were some slight internal structure artifacts when using multiple colors, affecting the extrusion paths, but these didn’t impact the structural integrity of the parts.

The printer’s noise level is another pleasant surprise. With a maximum noise level of just 54 dB even during operation, it’s quiet enough to run in a home office without becoming a distraction.

For those who need even faster prints for rough prototypes, the Bambu Lab H2D supports quick nozzle changes. You can swap between 0.2mm, 0.4mm, 0.6mm, and 0.8mm nozzles, though the printer works best when both hotends have the same size nozzle installed. High-flow 0.4mm nozzles are also available for those who want to maximize speed without sacrificing too much detail.

Laser and Cutting Capabilities

If you’ve opted for one of the Laser Combo packages, the Bambu Lab H2D transforms from a capable 3D printer into a multi-function fabrication system. The 10W laser module will easily engrave wood, leather, and acrylic, and the more powerful 40W option will also cut thinner materials.

Switching between printing and laser operation is straightforward, involving a physical module change and some software adjustments. The included safety features specialized windows, air assist pump, and emergency stop button are essential for safe laser operation, and it’s good to see Bambu Lab prioritizing these aspects.

The cutting module with pen holder adds yet another dimension to the machine’s capabilities, allowing for precise drawing and cutting of paper, vinyl, and other thin materials. Combined with the 3D printing functions, this makes the Bambu Lab H2D a versatile tool for makers who work across multiple mediums.

Potential Issues and Solutions

During extensive testing, I encountered only a few minor issues. The most significant was during the first purge with a 2mm nozzle, when a large amount of purge material fell into the build chamber. This is typically an issue with PETG, which can be sticky and problematic, but applying Slices plastic repellent solved the problem entirely.

The printer’s build volume, while generous, comes with limitations when using dual nozzles. You can’t use the entire 350mm width for a single print, as the second nozzle needs space to operate. However, that isn’t a problem for most projects, and the extra ability to print with two materials far outweighs the slightly reduced usable build area.

Another consideration is the compatibility between materials. While TPU and PETG bonded well in testing, TPU and PLA didn’t adhere as effectively. This is more a limitation of the materials themselves than the printer, but it’s worth keeping in mind when planning multi-material projects.

Value Assessment

At $2,399 for the base model and up to $4,399 for the full laser combo, the Bambu Lab H2D represents a significant investment. However, when considering what you’re getting a dual-nozzle printer capable of high-speed printing with exotic materials, optional laser cutting and engraving, and an exceptional level of automation the price becomes more justifiable.

For professional makers, small businesses, or serious hobbyists who can make use of the multi-material and multi-function capabilities, the Bambu Lab H2D offers excellent value. Its combination of speed, precision and versatility means it can supplant several dedicated machines, which over the long term could save money and space.

For more casual users, the price might be harder to justify, especially if you’re primarily printing in a single material or don’t need the laser capabilities. In those cases, Bambu Lab’s less expensive options like the P1P might be more appropriate.

Conclusion

The Bambu Lab H2D is an exceptional machine and exactly what the market needs for true multi-function fabrication. It’s still missing a few refinements, like better privacy controls for its camera system, but the company’s rapid innovation and consistent firmware updates make it a worthwhile investment.

Retailing at $2,399 for the base model and up to $4,399 for the full laser combo, the Bambu Lab H2D is certainly not a budget option, but it is definitely one of the most versatile machines available to serious makers. With its enclosed design and advanced ventilation, the dual-nozzle capabilities and optional laser modules this machine is ideal for small businesses that need to prototype through multiple materials or produce finished goods. It’s also an excellent choice for makerspaces, especially with safety features that help manage the risks associated with high-temperature printing and laser operations.

For users already within Bambu AMS ecosystem, Bambu Lab H2D will connect with existing set up easily. Fast forward to 2023, you are not on a limitation to use only their special filament, this machine is compatible with multiple 3rd party filaments.

If the Bambu Lab H2D seems too expensive for your needs, the Bambu Lab X1C remains my top recommendation for high-quality enclosed printing at $1,450. The Prusa MK4 is also a solid choice for reliable printing with exceptional community support, currently priced at $999 for the assembled version.