Materialise secures EN 9100 certification, expanding aerospace 3D printing to certified metal components, enhancing supply chain agility.

Belgium’s Materialise Strengthens Aerospace Role with EN 9100-Certified Metal 3D Printing

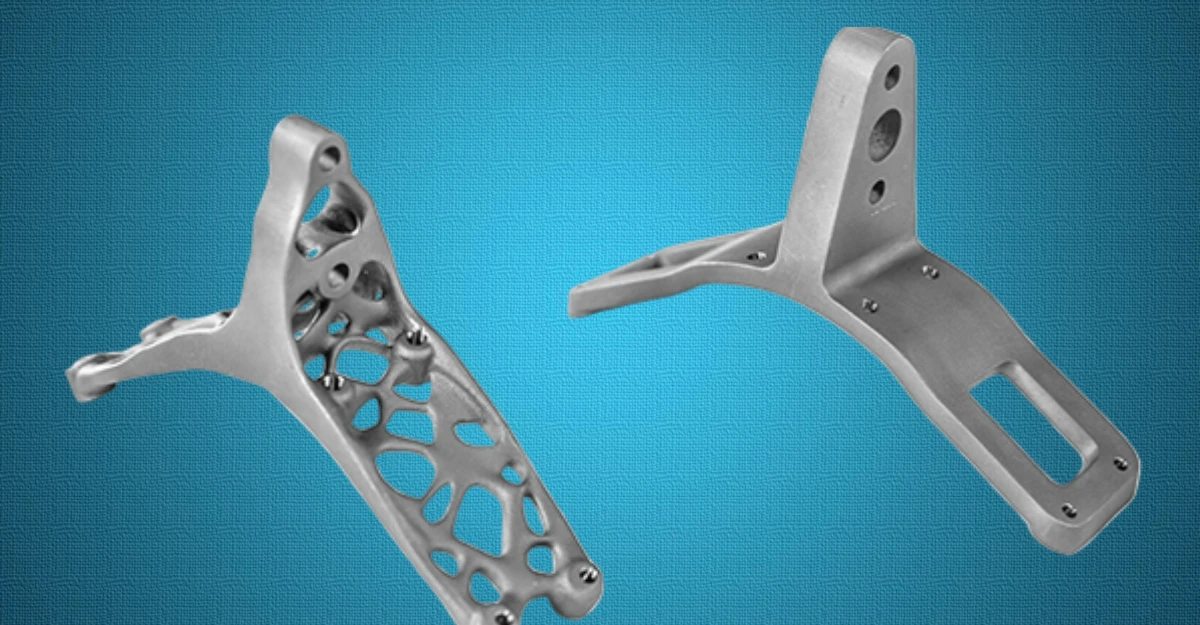

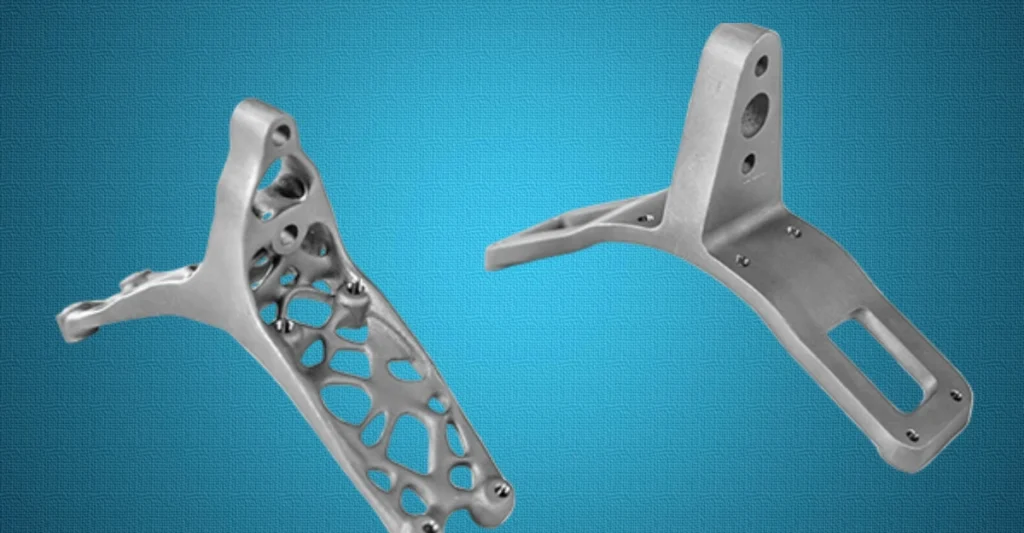

The Belgian metal 3D printing facilities of Materialise, a frontrunner in Additive Manufacturing (3D printing), have recently been certified with EN 9100, which allows them to manufacture certifiable aerospace parts. The certification—an addendum to ISO 9001— captures and expands the scope of isos compliance with aviation industry specific needs like aerospace traceability, process control, and compliance with regulations. This accomplishment enables the company to expand its role in the aviation and space industry’s supply chain to include the production of essential structurally critical metal components produced through additive manufacturing processes.

This new certification comes shortly after Materialise announced that it had also achieved EN 9100 approval for polymer 3D printing, a space in which it has already created over 500,000 functional aircraft parts. These consist of OEM, tier supplier and MRO components. Now, with metal capabilities added, the company also serves high-demand categories that require durability and precision, including engine housings, structural brackets, and interior trims.

Unlocking New Opportunities in Aerospace

Erik de Zeeuw, Materialise’s Aerospace Market Manager, emphasized the strategic advantages of metal 3D printing for the sector. “Low-criticality parts like seat bezels, ducts, and housings often require frequent repairs or replacements but in small quantities,” he said. “Additive manufacturing eliminates tooling costs and setup delays, enabling digital ‘on-demand’ inventories. This ensures faster sourcing, avoids excess stock, and reduces total cost of ownership (TCO).”

This accreditation aligns with Materialise’s broader certification portfolio which contains a POA from EASA and AIPI compliance issued by Airbus. With these certifications, the company molded fully assembled flight-ready components claiming FORM 1 compliance, a prerequisite for aerospace clientele. In 2023, Materialise also earned the mark of Trustworthy Partner awarded by Airbus for scoring maximum points in their Quality Maturity Assessment, thereby cementing Materialise’s MRO reputation and OEM partnership renown in Quality.

Industry Trends: Certifications Drive Aerospace AM Adoption

Materialise’s milestone underscores an emerging trend among additive manufacturing companies: focusing on aerospace certifications. U.S. based A3D Manufacturing recently attained their AS9100 certification while Additive Flight Solutions and Keselowski Advanced Manufacturing certified their CNC and additive operations for aerospace production. These contracts are usually required by big-players like Boeing and Lockheed Martin.

Beyond metals, standardization efforts are expanding into other sectors. In December 2023, ISO and ASTM jointly published ISO/ASTM 52939, a framework for certifying non-metallic 3D-printed structural elements in construction. Though not applicable to aerospace, the standard highlights the broader push toward formalizing additive manufacturing quality benchmarks.

Cost Efficiency and Supply Chain Resilience

Metal 3D printing’s economic benefits are particularly compelling for aerospace, where low-volume, high-value parts dominate. Traditional manufacturing methods involve costly tooling and minimum order quantities, which additive processes eliminate. “Airlines no longer need to stockpile parts or face delays due to supply chain bottlenecks,” de Zeeuw noted. “They can produce exactly what they need, when they need it, while iterating designs for continuous improvement without prohibitive costs.”

This nimbleness is important for the industry trying to recover from pandemic driven disruptions along with trimming down operational idle time. A case in point: A static aircraft suffering from prolonged wait times exploits preposterous sums of money that can surpass $100,000 in losses for each day spent waiting for an uncommon replacement component. In such cases, Materialise’s certified solutions which make use of digital inventories and localized production can avoid such risks.

Read more : Unique PC Mods You Can Make With a 3D Printer

Future Outlook

Materialise plans to collaborate with aerospace stakeholders to identify additional components suitable for metal 3D printing. De Zeeuw highlighted ongoing projects to qualify heat-resistant alloys for engine applications and lightweight titanium parts for satellite systems. The company also aims to integrate artificial intelligence for real-time quality monitoring, further enhancing process reliability.

With certification milestones shifting, Materialise’s knowledge in both polymers and metals enables it to seize opportunities in the $15 billion aerospace additive manufacturing market, expected to expand at a compound annual growth rate of 20% through 2030. Since regulators and OEMs are beginning to adopt AM more readily, the company is set to spearhead advancements in areas where optimal precision, rapid production, and adaptability are critical.