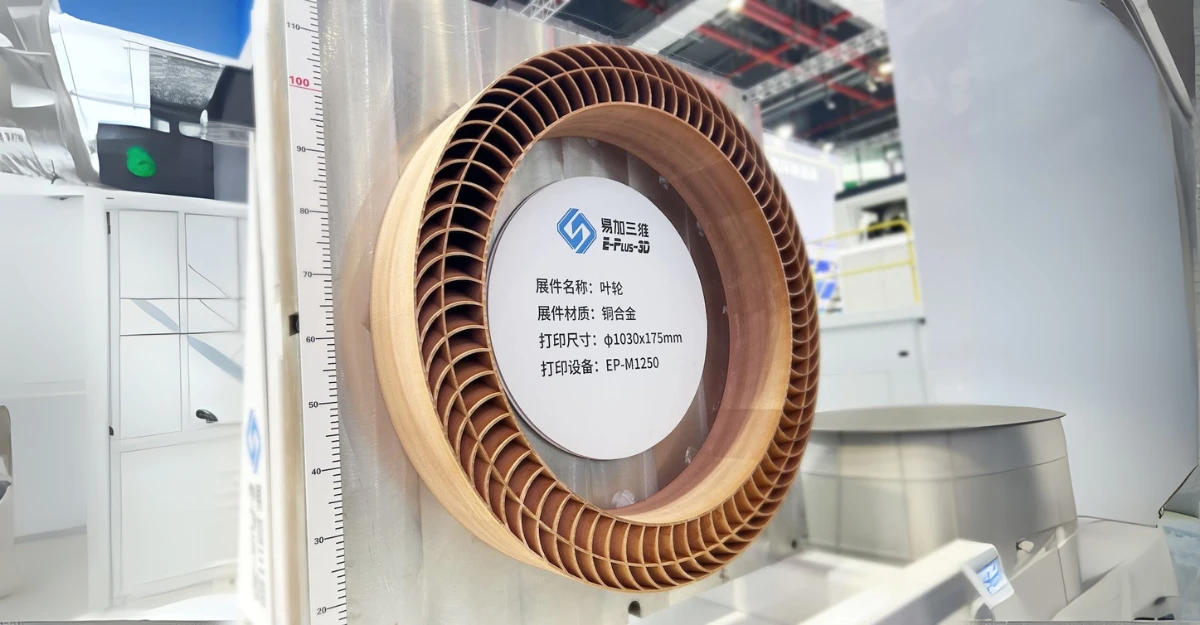

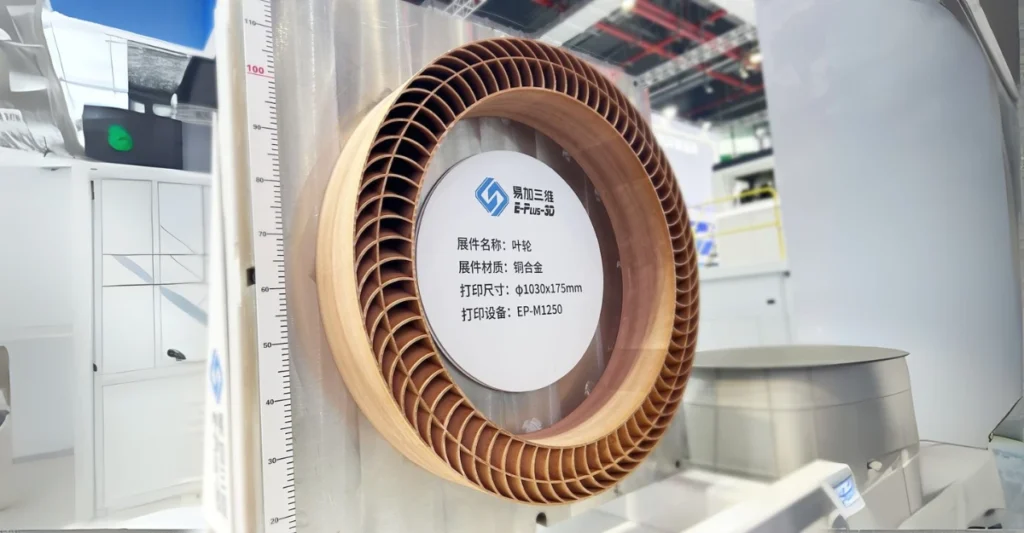

Eplus3D unveiled its latest advancements in copper 3D printing at TCT Asia 2025, overcoming challenges with high reflectivity and achieving 99.97% part density through process optimizations.

Eplus3D has taken the spotlight at TCT Asia 2025 with its latest breakthrough in large-format copper 3D printing. The Chinese additive manufacturing (AM) leader claims to have tackled one of the industry’s toughest challenges: copper’s low absorption and high reflectivity in red laser-powered powder bed fusion systems.

According to Eplus3D, the key to this achievement lies in process optimizations rather than hardware upgrades. The company has validated the mechanical properties of copper-chromium-zirconium (C18150), ensuring part stability and long-cycle reliability. Impressively, Eplus3D’s copper parts now reach a density of 99.97%, a significant milestone for metal AM.

This isn’t the first time Eplus3D has pushed the envelope in AM. The company is known for its massive build volumes and multi-laser systems, such as the EP-M2050 with a 2050 x 2050 x 2000 mm build volume and the 16-laser EP-M1550, which can be upgraded to 25 lasers. Eplus3D has also delivered over 100 ‘super-meter’ metal 3D printers, with more than 40 systems exceeding one meter in build size across all axes.

TCT Asia 2025 continues to be a hub for innovation, with Eplus3D’s copper printing advancements standing out alongside other notable launches, including Farsoon Technologies’ 32-laser FS1521M-U system. As Eplus3D expands globally—recently entering the UK market—its latest developments highlight the growing potential of copper 3D printing for high-density, high-reliability applications.