FAMU-FSU College of Engineering awarded $5M by NASA to develop 3D printing technologies enabling sustainable space exploration and biomedical advancements.

FAMU-FSU College of Engineering Pioneers 3D Printing Innovations for Space with $5 Million NASA Grant

Through pioneering 3D printing technologies, researchers at the FAMU-FSU College of Engineering intend to reshape the future of space exploration with the aid of a $5 million grant from NASA. The goal is to develop sophisticated manufacturing systems that would allow astronauts to fabricate essential parts, ranging from radiation shields to even fully operational human tissues, in space, consequently minimizing dependence on Earth while increasing flexibility for missions.

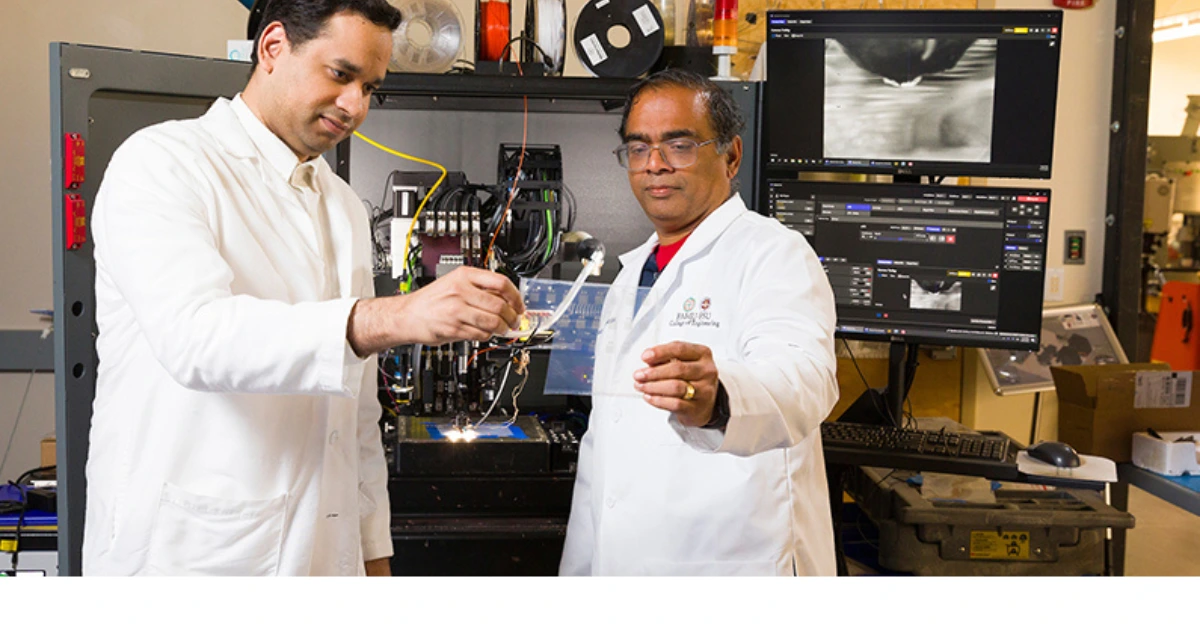

The project’s team includes scholars from seven institutions which are Florida State, NASA’s Goddard Space Flight Center, and the Mayo Clinic, under the direction of Professor Subramanian Ramakrishnan from the Department of Chemical and Biomedical Engineering. The interdisciplinary collaboration aims to develop new composites and innovative processes for the Moon, Mars, and outer space.

Revolutionizing In-Space Manufacturing

The development of “space-grade” inks for 3D printing sensors, antennas, flexible electronics, and radiation shielding MXenes, specially 2D materials washers, alongside metallic nanoparticles will enable the creation of technologies fundamental for long-duration missions. Ramakrishnan remarked about the transformative impact of the technology: “Consider having the capability to print sensors or even tissues during mid-mission. This could transform the approach we take towards exploration—making missions more sustainable and resilient to paradigm shifts.”

A distinct advantage qualifies EHD printing which utilizes electric fields to systematically position nanoparticles, in conjunction with laser curing. The technique enhances production speed, while maintaining the stringent materials integration build-up needs for the International Space Station (ISS) or bases on the moon.

Harnessing Lunar and Martian Soil

Exploiting materials beyond Earth seems to be one of the boldest goals for this project. The goal of Ramakrishnan’s team is to create inks out of lunar and Martian regolith (soil) for 3D printing functional structures on-site. “This makes it possible to get heavy materials from Earth which incurs great transportation expenses and risks,” he explained. The use of local materials would characterize a gradual shift toward sustainable habitats and infrastructure on other worlds.

Cutting-Edge Equipment and Collaborations

In addition to the NASA grant, the team received funding from the National Science Foundation (NSF) amounting to $700,000 to procure a sophisticated nScrypt 6-axis 3D printer. This advanced system is capable of printing complex patterns on cylindrical geometries which are suitable for Medical devices and Aerospace parts. “This printer permits us to develop innovative sensors specifically designed for NASA and experiment with cutting-edge ink formulations,” Ramakrishnan added.

Collaborators like Richard Liang from FAMU-FSU and Emily Pritchard from FSU’s Office of the Provost bring expertise in sensor integration and materials science. Meanwhile, NASA’s Margaret Samuels contributes insights from Goddard Space Flight Center, ensuring the technologies align with mission requirements.

Biomedical Breakthroughs in Microgravity

Beyond hardware, the project explores biomedical frontiers. Co-Director Jamel Ali investigates how human cells self-assemble in microgravity, a critical step toward 3D printing tissues and organs in space. “Understanding cell behavior in low-gravity environments could revolutionize regenerative medicine,” said Ali, who partners with the Mayo Clinic to study therapeutic cell expansion. His team also develops guidelines for 3D printing on irregular surfaces, merging biomaterials with semiconductor nanomaterials for dual-use applications.

Earthbound Applications

Although the research focuses on challenges related to space, its impact is felt on Earth as well. The technologies developed for the advanced sensors and materials may be instrumental in transforming businesses such as healthcare, energy storage, and optics. For example, medicine imaging devices could be improved with new radiation-shielding inks and flexible circuits could be incorporated into wearable technology.

A Vision for Sustainable Exploration

NASA’s sharp focus on in-space manufacturing (ISM) underscores their investment for deep space exploration purposes. According to Ramakrishnan’s statement, “By allowing astronauts to manufacture tools on-demand, we reduce costs and risks associated with launching missions, ensuring a sustainable human presence in space.”

This initiative is also in alignment with the Artemis program developed by NASA which plans to place a permanent lunar outpost by the 2030s. FAMU-FSU’s developments would aid in the construction of the 3D-printed habitats, spare parts fabrication, and even food cultivation.

Read more : Stanford Unveils Ultra-Fast Microscale 3D-Printing Method

Looking Ahead

With the grant, FAMU-FSU cements its role as a leader in materials science and aerospace innovation. The college’s interdisciplinary approach—bridging engineering, biomedicine, and planetary science—exemplifies the collaborative spirit needed to tackle humanity’s next giant leap. As Ramakrishnan put it, “We’re not just building tools for space. We’re redefining what’s possible, both out there and here at home.”