A new demo shows Formlabs’ Rigid 10K resin molds surviving over 500 automated injection molding, challenging traditional metal molds for small-batch production.

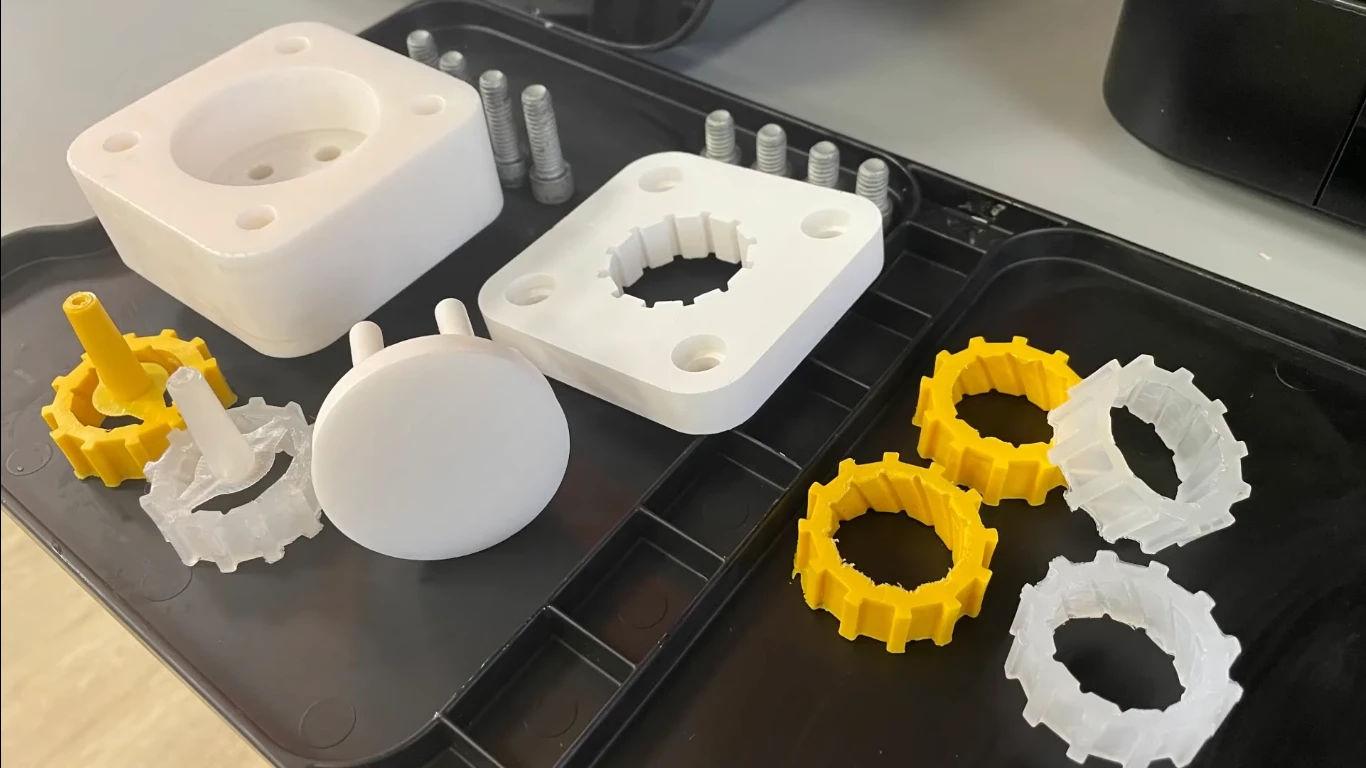

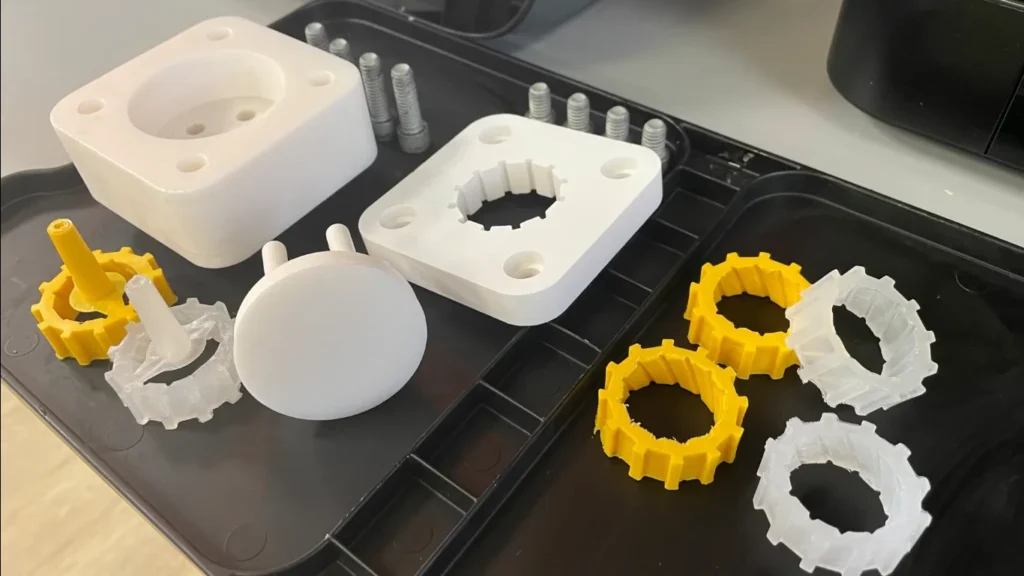

A recent demonstration by an injection molding specialist has revealed that 3D-printed resin molds can withstand the rigors of real injection molding far longer than skeptics might expect. The molds, fabricated on a Formlabs Form3+ using Rigid 10K resin, reportedly survived over 500 automated cycles while producing functional parts in polypropylene.

The setup isn’t for the faint of budget, requiring both a high-end resin printer and an APSX-PIM machine (priced around $13,500). But for small-batch manufacturers, the trade-off could be worthwhile: faster turnaround and stronger parts compared to 3D printing each piece individually.

While these resin molds won’t replace hardened steel for mass production, the experiment highlights a growing niche bridging prototyping and low-volume manufacturing with additive manufacturing’s geometric flexibility. Skeptics might question longevity, but 500 cycles is nothing to dismiss for certain applications.

Also read: 3D Printing in Academia Shapes Architecture’s Future

It’s not the first attempt at 3D-printed molds, but the results add weight to the argument that hybrid approaches could reshape small-scale production. Video proof, as they say, awaits after the break.