Fraunhofer IKTS installs AMAREA’s MMJ ProX system to advance multi-material 3D printing research.

The Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) has installed a new MMJ ProX 3D printing machine from spin-off company AMAREA Technology, significantly enhancing the institute’s research capabilities in multi-material printing.

The system, featuring precision droplet technology, further strengthens the institute’s position in developing advanced additive and hybrid manufacturing applications, particularly with ceramic materials. Operating with droplet volumes between 0.5 and 50.0 nanoliters and layer thicknesses from 70 to 300 µm, the machine delivers exceptional precision for complex components.

“We are delighted that Fraunhofer IKTS is among the first customers that use our system to further develop new products and thus to expand the market for Multi-Material applications,” said Steven Weingarten, developer of MMJ technology and co-managing partner at AMAREA Technology.

The MMJ ProX system boasts a substantial build volume of 530 x 300 x 200 mm, accommodating both small and large-scale complex components. Unlike conventional manufacturing methods that require extensive effort to achieve tailored material properties, this technology enables precise control over hardness, flexibility, conductivity, and chemical resistance within a single print job.

Equipped with six printheads, the version installed at Fraunhofer IKTS can process up to six different materials simultaneously. This capability opens applications across aerospace, electronics, mechanical engineering, energy, and medical sectors, with additional potential in specialized fields such as jewelry and watchmaking.

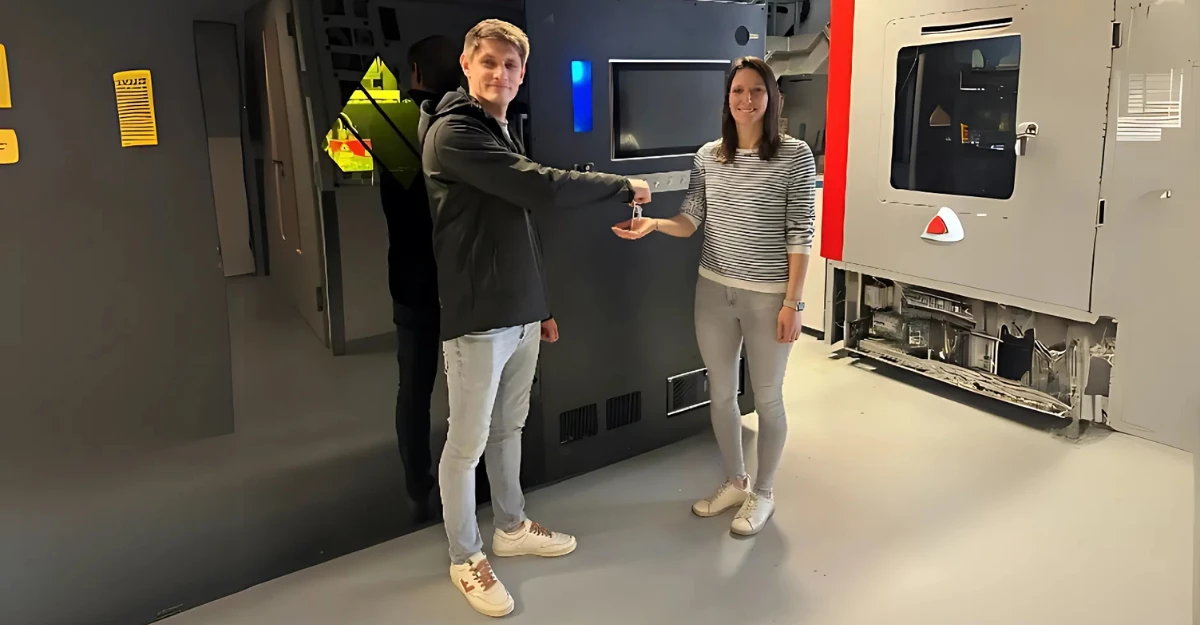

MMJ ProX 3D printer successfully handed over at Fraunhofer IKTS by AMAREA Technology CEO Steven Weingarten to Lisa Gottlieb, Research Associate at Fraunhofer IKTS. Photo courtesy of AMAREA Technology.

The Multi Material Jetting (MMJ) technology at the core of the system deposits particle-filled thermoplastic materials with extreme precision, placing material only where needed. This approach ensures efficient fusion and layer formation within fractions of a second, reducing post-processing requirements and improving material utilization.

According to AMAREA Technology, the system allows users to fine-tune porosity or create fully dense structures depending on application needs. The machine’s compatibility with various material classes makes it adaptable to different production requirements, while its rapid cooling capability ensures instant solidification for dimensional stability.

Over the last few years multi-material 3D printing has found its niche across industries, including in dental and medical applications. Early 3D printing developments such as 3D Systems’ jetted monolithic denture solution and Brinter’s multi-fluidic bioprinting printhead are expanding horizons for multi-material printing at niche applications.