Horizon Microtechnologies validates its proprietary copper coatings through rigorous stress tests, ensuring longevity for high-stakes applications like aerospace and microelectronics.

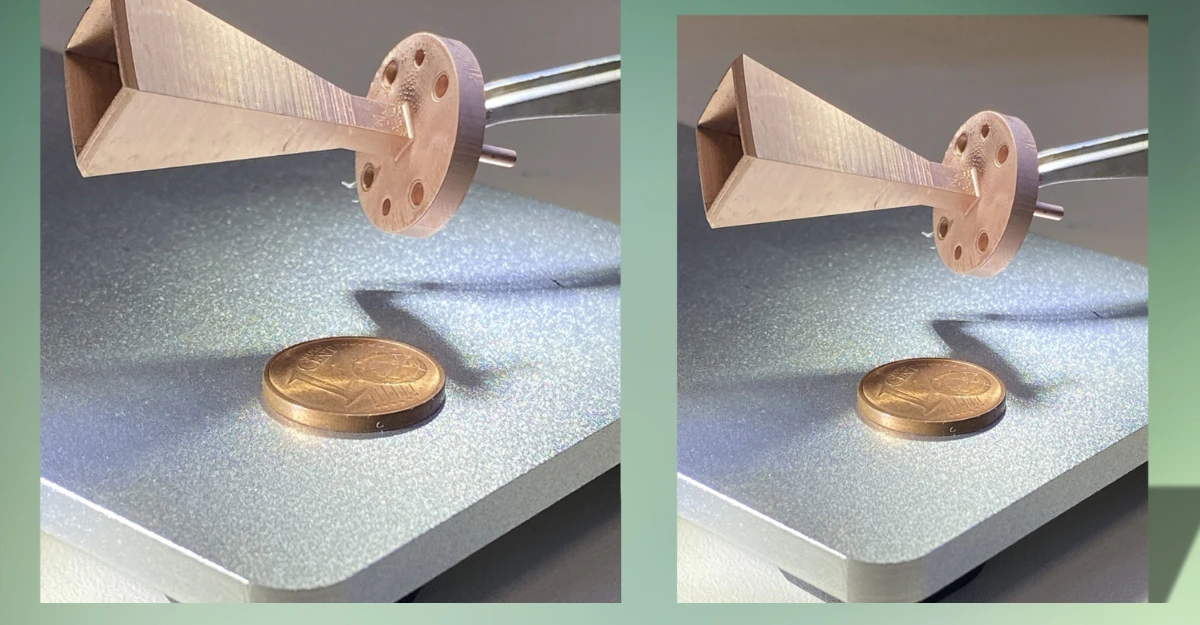

In a noteworthy advancement for precision engineering, Horizon Microtechnologies reported the remarkable resilience of its copper-scaling microstructures protective coatings proprietary to the company, aluminating 3D printed microstructures. The achievement, corroborated by a set of rigorous stress evaluations, places the technology as a leader with the potential to transform the aerospace, electronics, and space systems industries that depend on sturdy metal parts.

To mitigate these issues, Horizon PCT subjected its passivated copper coatings to extreme environmental simulation tests aged under high temperature, high and low humidity, sub-zero cold, atomic oxygen (as found in low-Earth orbit) and other chemically or mechanically demanding conditions. The results were noteworthy: standard copper coatings were almost entirely destroyed by heat and humidity, while Horizon’s treated copper showed only minor changes in discolored copper oxidation and maintained structural and electrical integrity. Cold tests on the coatings also presented no changes to the materials, further supporting the versatility.

Horizon Microtechnologies’ CEO, Andreas Frölich, commented, “Our results alleviate the enduring worries associated with copper aging in microfabricated components. With our passivation technology, these coatings are not only viable, they are remarkably tough even in the most extreme environments.”

The implications are profound for industries where component failure is not an option. In space systems, for instance, atomic oxygen can erode unprotected metals, jeopardizing mission-critical hardware. Similarly, electronics and RF components demand stable conductivity over decades, a requirement Horizon’s coatings now credibly meet. The company’s approach eliminates the need for bulky protective layers, enabling sleeker, more efficient designs without sacrificing durability.

While initial tests focused on accelerated aging scenarios, Horizon plans to conduct long-term evaluations aligned with industry standards. Early data, however, already suggest the coatings could outlast conventional alternatives by years, reducing maintenance costs and downtime in sectors like telecommunications and defense.

Read more : Stratasys Boosts 3D Print Speeds with New Neo800+ System

This progress emphasizes the increasing importance of additive manufacturing in critical engineering disciplines. By overcoming the copper durability constraint with the Horizon solution, designers are now able to move the frontier of 3D printing further producing smaller and more intricate parts which still function effectively.

The adoption of microfabrication approaches within new industrial level technology is set to Horizon’s innovation. It’s integration of precision machining along with advanced material science precisely engineering worlds of new high strength, high functionality parts avalible is exceeding the previously belivable standards, where even the most miniature components are ready to endure insurmountable challenges.