Endeavor 3D introduces HP’s innovative PA 12 Flame Retardant material, offering a sustainable solution for industrial 3D printing applications.

Endeavor 3D announced Friday the availability of HP PA 12 Flame Retardant (FR), a halogen-free polymer material designed for advanced 3D printing applications. The company is among the first North American contract manufacturers validated by HP to produce components using Multi Jet Fusion (MJF) technology.

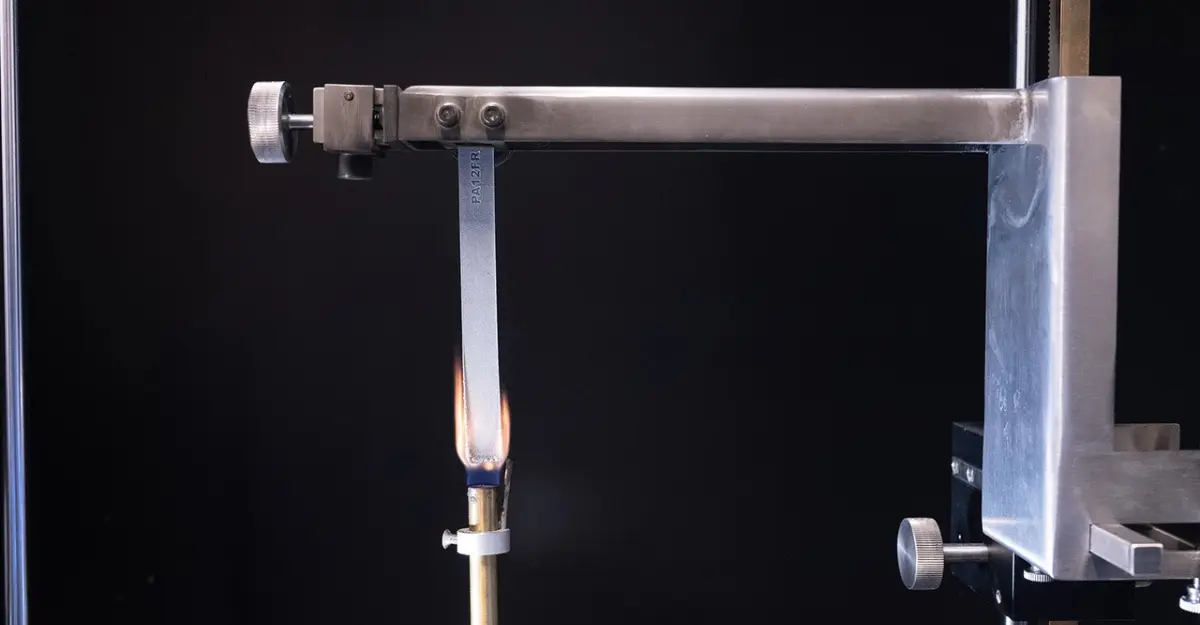

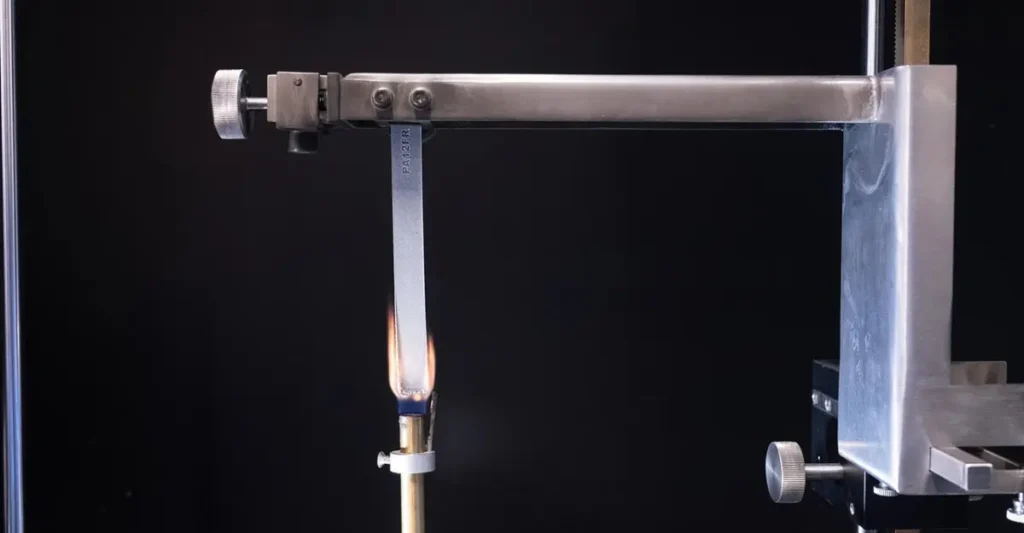

At 2.5-mm thickness, the new material boasts UL 94 V0 certification, ensuring it conforms to the strict safety and flammability protocols. The polymer offers 60% powder reusability ratio and is said to serve lower cost applications in specialist sectors such as electrical, robotics and industrial manufacturing.

HP 3D PA 12 FR, co-developed with Evonik, is specifically designed for housing electronic components, battery holders, cable guides, and home appliance housings. It provides an excellent surface finish at a lower cost with less waste.

“This material is a major advancement towards enabling manufacturers to cost-effectively create flame-retardant components,” said Phil Arnold, Endeavor 3D CEO. The announcement marks a potential epic failure in conventional additive manufacturing performance and cost expectations.