SpaceFactory leverages large-scale 3D printing to help Huntsville businesses combat supply chain disruptions caused by tariffs through cost-effective domestic production.

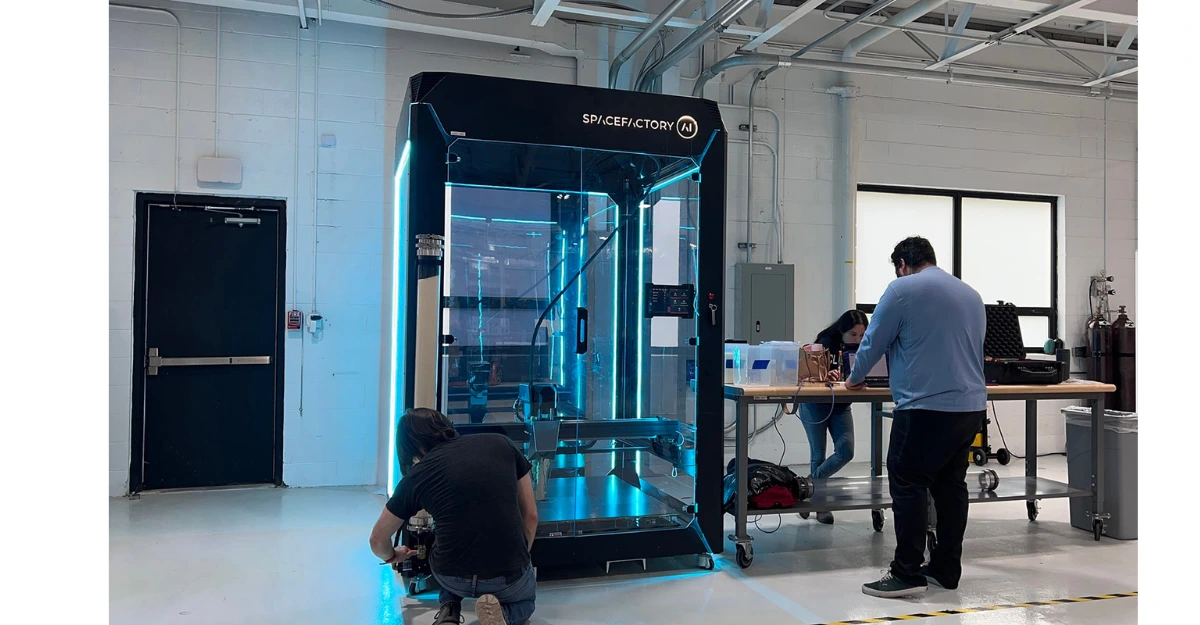

SpaceFactory, located in Huntsville, is working to enhance local manufacturing by using state-of-the-art 3D printing technologies to deal with supply chain problems created by tariff wars. The company’s 3D printers with industrial scale additively manufactured capabilities of producing parts sized 4’ x 4’ x 5’ can empower local businesses to shift to domestic production which will enable them to reduce reliance on their foreign suppliers.

In the following months, SpaceFactory will partner with local companies to offer DFAM (design for additive manufacturing) consulting and pilot programs for feasibility studies, prototyping, and testing— all of which incur negligible initial expenses. These programs are intended to assist advanced projects from custom-purpose devices to tailored consumer items at all stages of the innovation lifecycle.

“Our goal is to empower Huntsville businesses to build resilient supply chains while expanding their market reach,” said SpaceFactory CEO David Malott. “Domestic production isn’t just about solving immediate challenges—it’s a gateway to new opportunities.

Read more : Stratasys Boosts 3D Print Speeds with New Neo800+ System

Local companies interested in joining the initiative can contact SpaceFactory via contact@spacefactory.ai for a free consultation. By merging cutting-edge technology with community-focused partnerships, SpaceFactory positions Huntsville as a hub for agile, future-ready manufacturing.