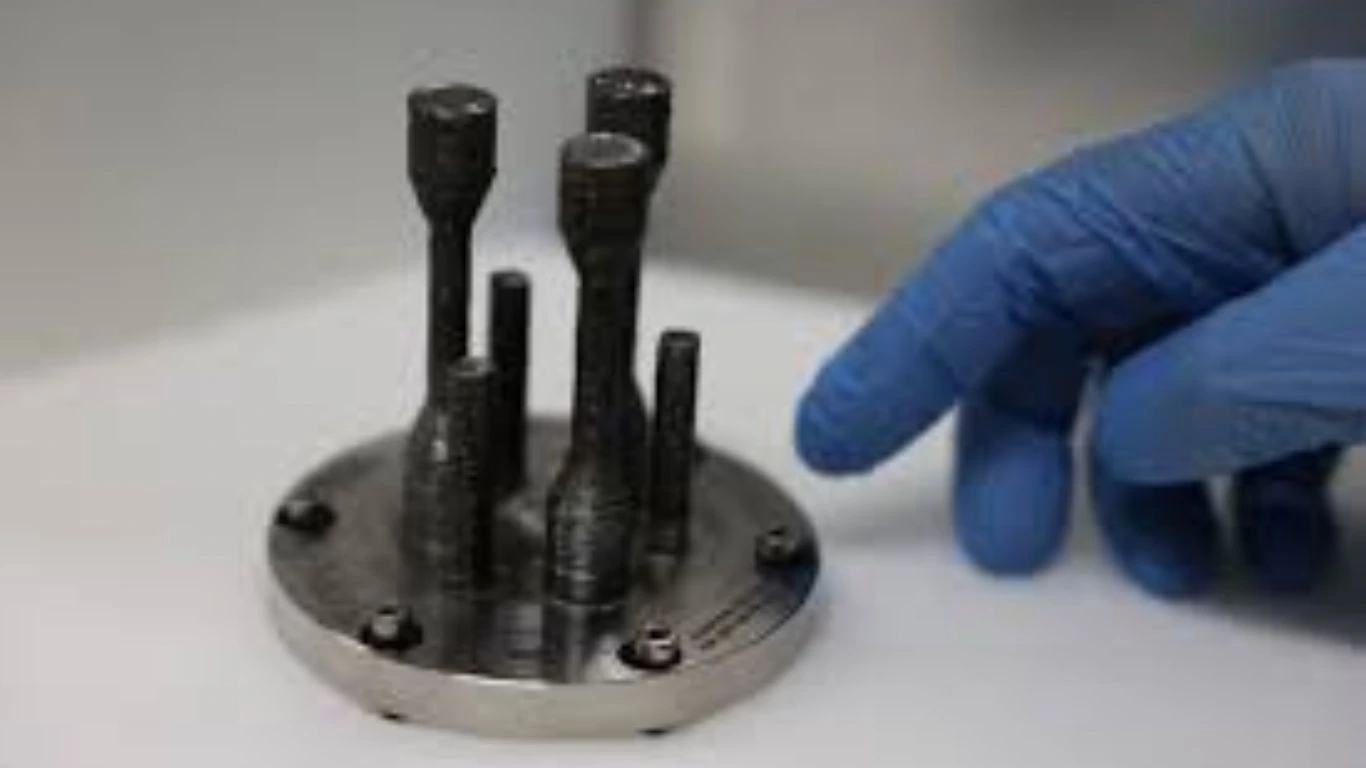

First-ever space-printed metal object returns to Earth for scientific analysis.

A piece of metal that was not produced on Earth is under the watchful eye of researchers at the European Space Agency (ESA).

This sample was produced on board the International Space Station (ISS) with the use of a specially designed metal 3D printer developed by Airbus Defence and Space an ESA and has since been brought back to Earth to be analysed. This is a world-first achievement that could change the face of space missions in the coming years.

The printer, installed in the Columbus module by astronaut Andreas Mogensen, has produced several prints since its activation. After initially producing an ‘S’-shaped curve, it manufactured two complete samples, reaching important milestones for the technology.

ESA scientists will study these samples to understand microgravity’s effects on the printing process. This research is vital for future space missions where 3D printing could become essential.

The innovation represents a significant step toward self-sufficiency in space. The ability to manufacture spare parts or tools directly in orbit would reduce dependence on resupply missions from Earth.

Metal 3D printing in space is just the beginning. The results could enable more ambitious applications, including constructing structures directly in space.

Read more : New Functional 3D Materials from Inslogic Debut at RAPID 2025

This technological advancement shows 3D printing‘s potential to change how we explore space while highlighting successful collaboration between space agencies and industrial partners.