RAF transforms 1970s fighter jet components into cutting-edge aircraft parts through groundbreaking recycling and 3D printing technology.

The UK’s Royal Air Force has found a way to turn their retired warriors into tomorrow’s cutting-edge aircraft, and it’s more than just clever recycling – it’s a game-changer for sustainable aerospace manufacturing.

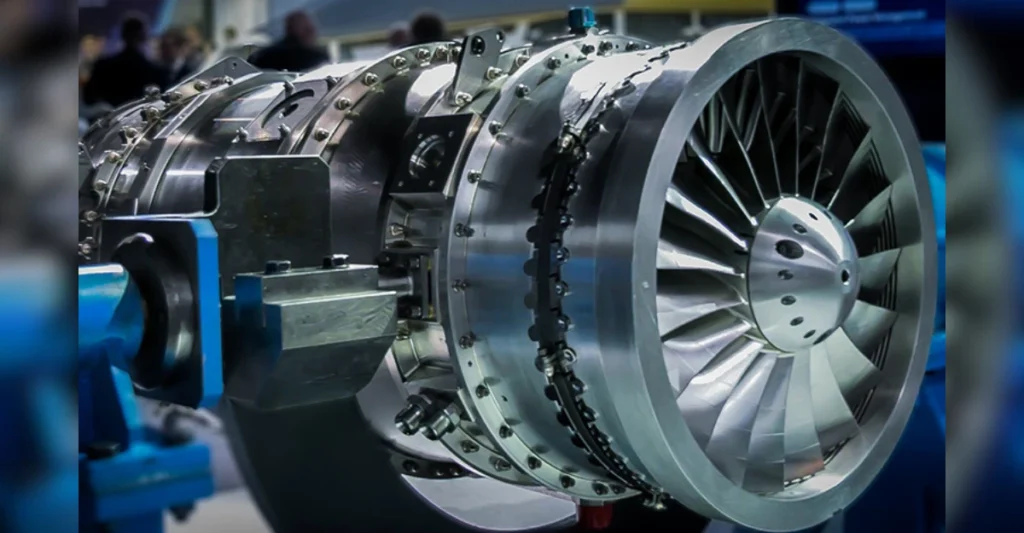

The breakthrough comes from Additive Manufacturing Solutions, where they’re not just melting down old jets – they’re transforming them into something extraordinary. Take, for example, the Panavia Tornado, which reigned over the skies from 1980 to 2019, its turbine blades making up the nose cone of the RAF’s next generation fighter jet engines.

The secret sauce? A fascinating process that’s surprisingly similar to how nature makes hailstones. The recycled metal gets melted down and sprayed into a high-pressure argon jet, where it transforms into perfect spherical particles – essential for quality 3D printing. These tiny metallic raindrops, each half the thickness of a human hair, become the building blocks of new aircraft components.

What makes this particularly clever is how it solves multiple challenges at once. The RAF gets to repurpose its stockpile of valuable materials like Ti64 (a specialized titanium alloy) while sidestepping the need to source materials from sanctioned countries like Russia. “The world is more expensive than it used to be,” notes Robert Higham from Additive Manufacturing Solutions. “We can make them as cost effectively as possible.”

The first success story? A freshly printed nose cone for Rolls Royce’s Orpheus jet engine, destined for the Future Combat Air System. It’s part of a bigger picture that includes the BAE Systems Tempest, a sixth-generation fighter jet that’s set to define the future of the RAF’s aerial capabilities.

This is not just recycling — it is rethinking how we design the next generation of military aircraft. One vintage fighter at a time, the RAF is proving that yesterday’s defenders can help forge tomorrow’s protectors.