Hokkaido University researchers develop affordable 3D-printed robotic system that automates complex materials synthesis processes.

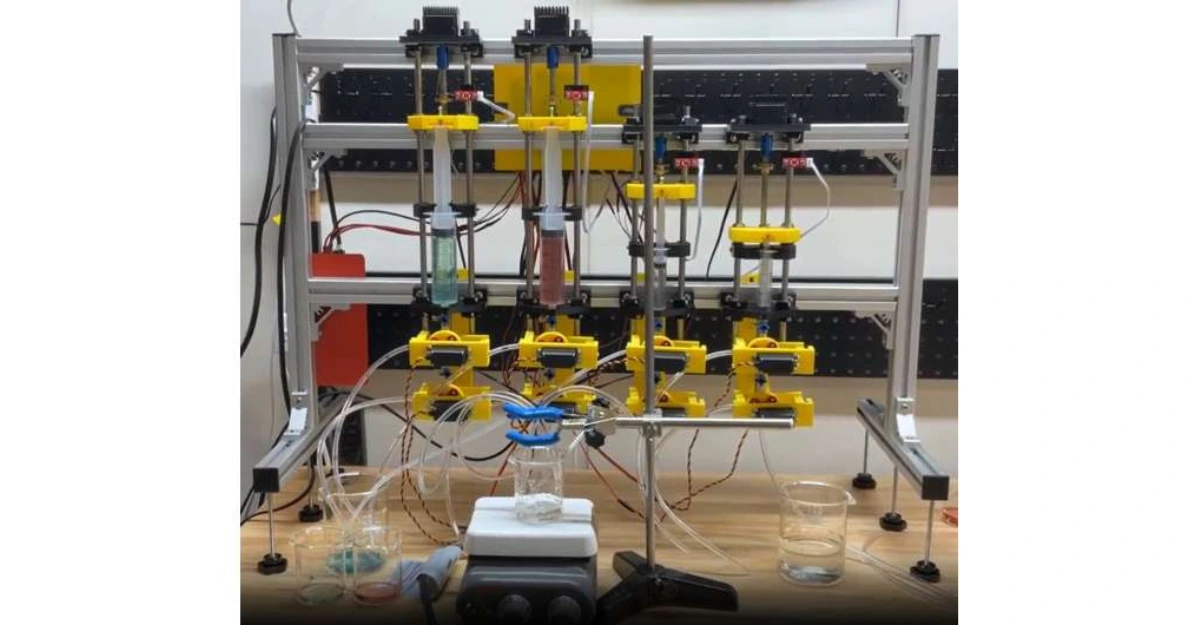

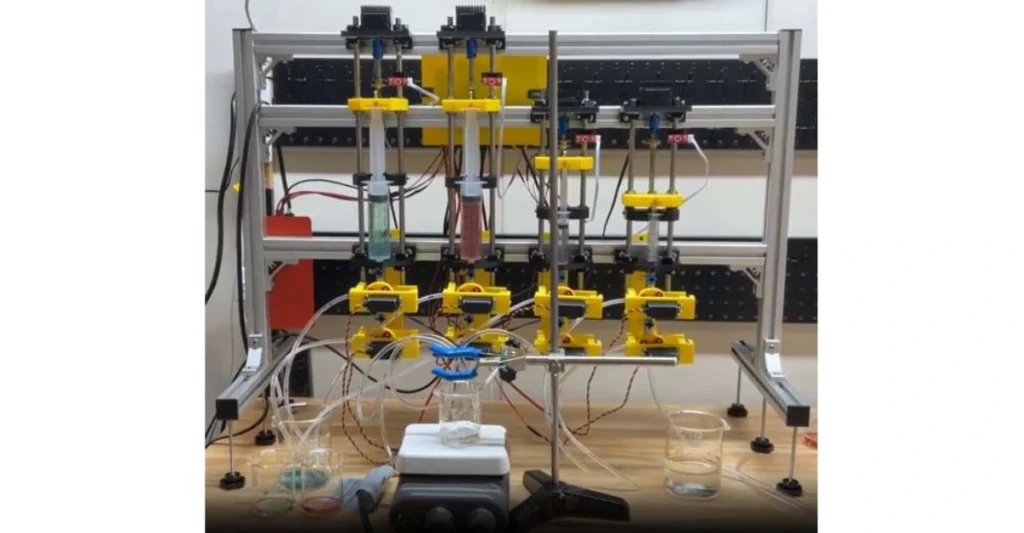

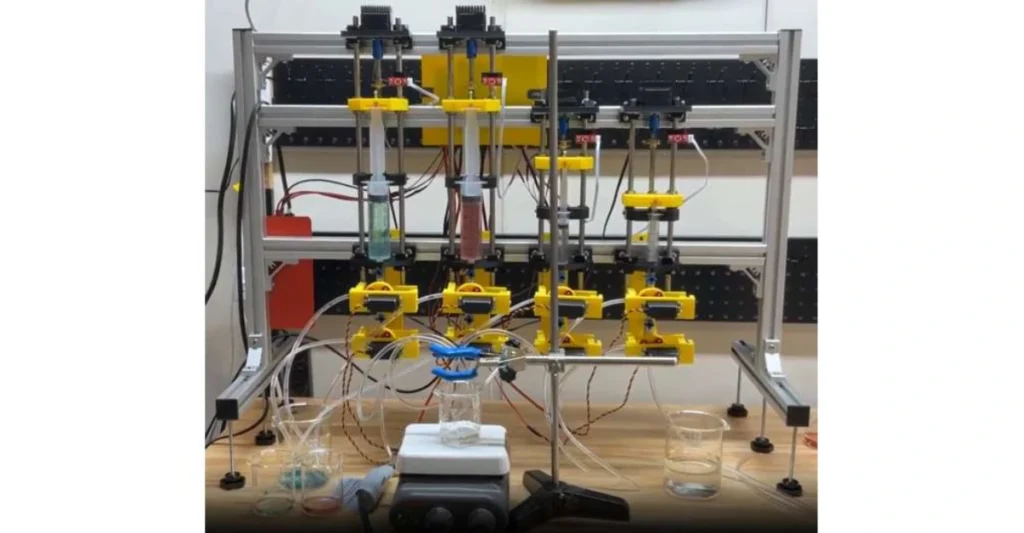

The open-source FLUID robot, developed by researchers at Hokkaido University, was unveiled Friday as a breakthrough solution for materials synthesis that could dramatically reduce barriers to advanced research.

The FLLUID-act was printed using a 3D printer and is provided with standard electronic parts, thereby providing a low-cost alternative to off-the-shelf commercial systems.

By applying FLUID to automate the co-precipitation process of cobalt and nickel, researchers by Professor Keisuke Takahashi proved that the system was able to produce binary materials with high precision.

“By adopting open source, utilizing a 3D printer, and taking advantage of commonly available electronics, it became possible to construct a functional robot that is customized to a particular set of needs at a fraction of the costs typically associated with commercially available robots,” said Mikael Kuwahara, the lead author of the study.

FLUID’s hardware consists of four independent modules, each equipped with a syringe, two valves, a servo motor for valve control, and a stepper motor to precisely control the syringe plunger. These components are connected to microcontroller boards that receive commands from a computer via USB.

User-friendly software governs the robot’s operation and reports back with real-time status information and sensor data, enabling experiment oversight at a distance, the researchers reported.

In a push to democratize access to cutting-edge research devices, the team has open sourced all design files of the Santa Elena robot, and scientists across the world can copy, or tinker with the robot, to suit their specific experimental necessities.

“This is all about democratizing the automation of materials synthesis, offering materials researchers an affordable and accessible new tool to boost innovation in the science of materials,” Takahashi said.

The development may benefit scientists working in low-resource areas or fields in which commercial devices are not available or are costly.

In the future, the researchers hope to expand FLUID’s function by adding additional sensors to monitor parameters such as temperature and pH, and broaden the types of chemical reactions the robot can handle, such as polymer mixing and organic synthesis.

Read more : Bambu Lab Unveils New H2D 3D Printer

An upgraded software package is also under development that provides macro recording to help automate repetitive tasks, and improved data logging to improve experimental reproducibility and data analysis.