Chinese manufacturer PioCreat partners with US-based Helio Additive to integrate Dragon optimization software into its 3D printers.

Chinese 3D printer manufacturer PioCreat has formed a strategic partnership with US-based startup Helio Additive to bring advanced simulation capabilities to its printer lineup. Under this new collaboration, all PioCreat G5 Ultra and G12 printers will now include a license for Dragon, Helio’s physics-based 3D print simulation and optimization software.

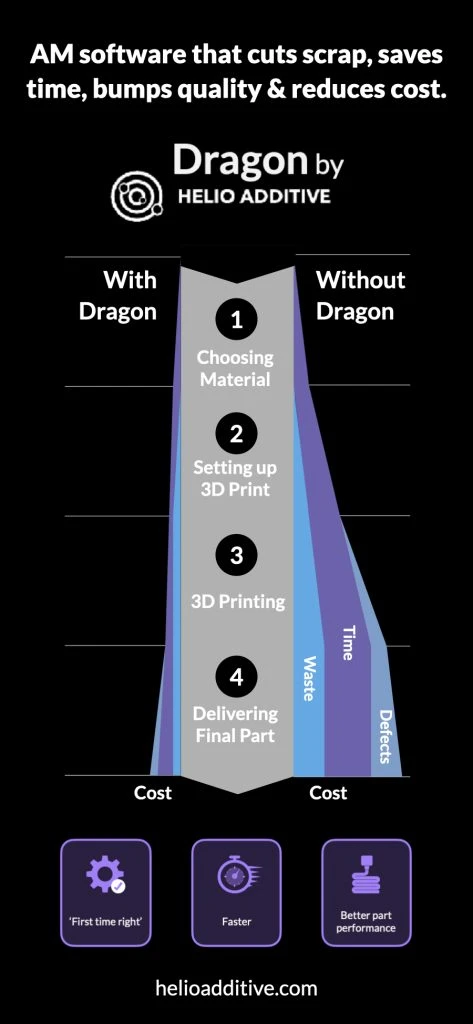

The integration aims to address common challenges in 3D printing through physics-driven automation. Dragon’s technology enhances layer bonding, reduces warping and defects, and expands the range of materials that can be reliably printed. Perhaps most significantly, the software accomplishes these improvements while simultaneously increasing print speeds.

“We built Dragon to get the most out of every 3D printer and this partnership with Piocreat makes it seamless for customers to see the advantages.” — David Hartmann, CEO, Helio Additive “The combination is a powerful step to make high-performance 3D printing more accessible and scalable.”

Beginning May 1, all new PioCreat 3D printers will ship with a trial version of Dragon. Customers can activate a full subscription through PioCreat’s reseller network or directly through Helio Additive.

The collaboration comes at a time of significant advancement in additive manufacturing software. Helio Additive launched its Dragon platform earlier in 2024, focusing on process simulation and optimization for large-format additive manufacturing (LFAM). The technology helps users set more effective process parameters through digital experimentation, dramatically reducing waste and engineering time.

In one case study cited by Hartmann, Dragon saved over 300 kilograms of material and four weeks of engineering labor, resulting in a 70% reduction in scrap for a single part.

This partnership is part of a broader trend of software innovation in the additive manufacturing industry. Other recent developments include Ai Build’s introduction of AiBuild 2.0, a cloud-based platform with enhanced automation features, and HYBRID Software subsidiary AMIS launching a beta version of its AMIS Pro software for binder jetting additive manufacturing.

For manufacturers using PioCreat’s printers, the Dragon integration promises to deliver more reliable printing with less manual intervention, potentially opening new applications for industrial 3D printing technology.