Pratt & Whitney introduces additive manufacturing repair process that dramatically reduces GTF engine service time and costs.

The replacement repair process for Pratt & Whitney’s GTF engine components was launched late this year, paving the way for significant reductions in service time and substantial cost savings across the company’s global operations.

The American aerospace manufacturer has developed a new additive manufacturing repair process that cuts service times by more than 60%. The technology is expected to be deployed throughout P&W’s global maintenance, repair, and overhaul (MRO) network once industrialization is complete. Company estimates suggest the new approach could recover approximately $100 million worth of parts over the next five years.

“A more agile, additive repair process allows us to better serve our customers by improving turnaround time, while reducing tooling costs, complexity and set up,” said Kevin Kirkpatrick, Vice President of Aftermarket Operations at P&W. “At the same time, it reduces our dependency on current material supply constraints.”

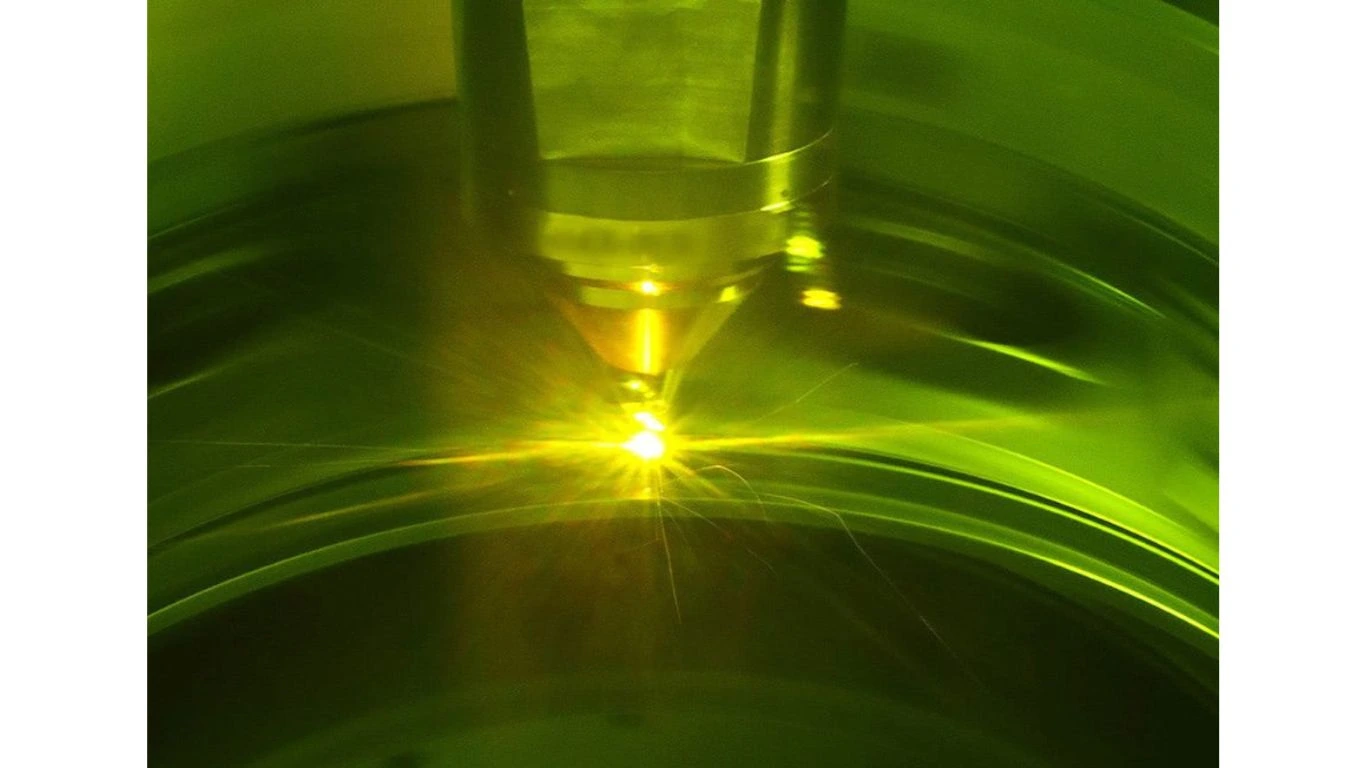

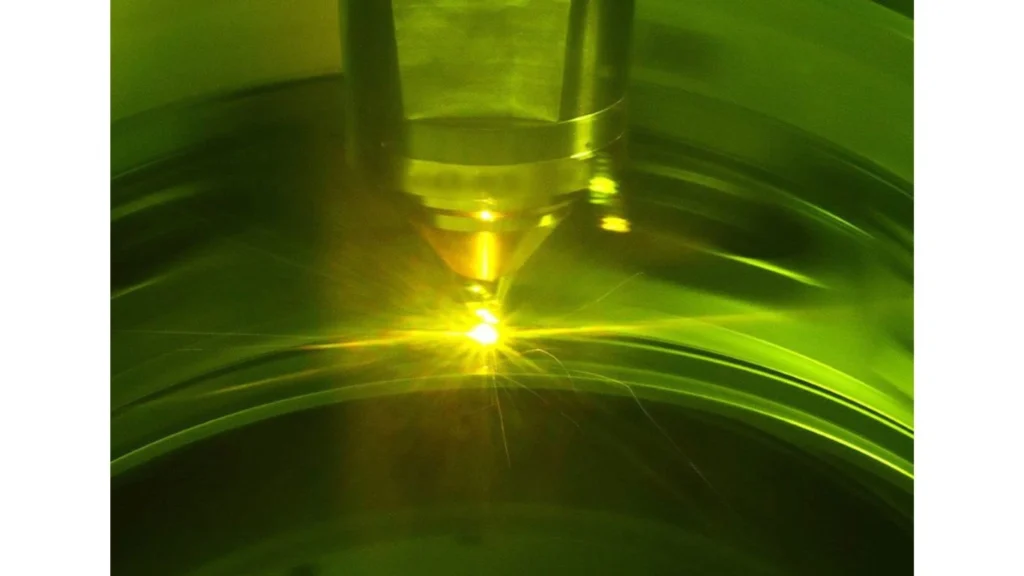

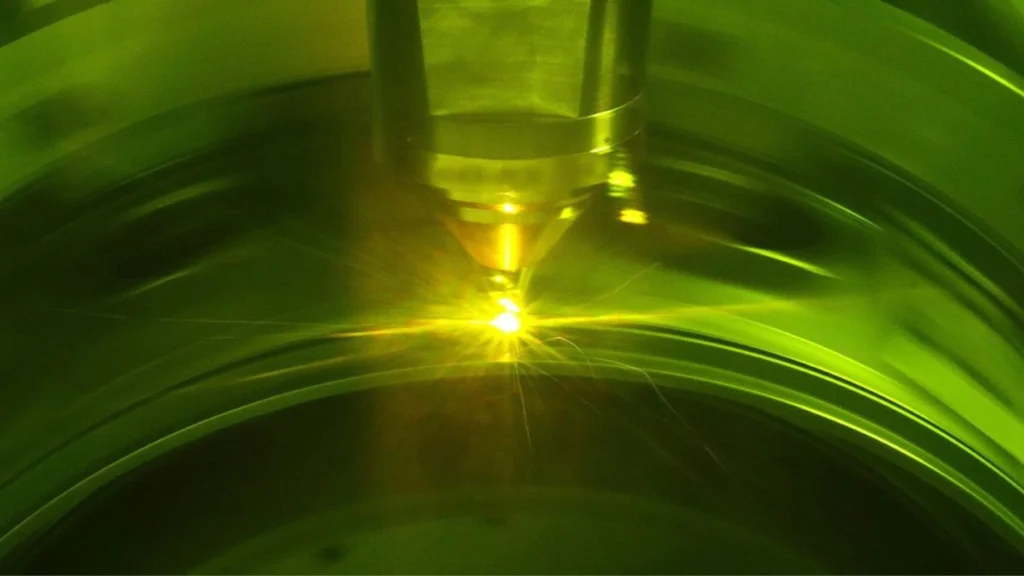

Developed at the company’s North American Technology Accelerator in Jupiter, Florida, the new process focuses on restoring structural case features of GTF engines. The approach utilizes directed energy deposition (DED) technology to apply material precisely where needed, eliminating several steps from traditional repair methods.

P&W reports that most time savings come from fewer machine changeovers and reduced heat treat cycles. The development was carried out in collaboration with the Connecticut Center for Advanced Technology (CCAT) and the RTX Research Center.

In its current capacity for structural repairs, the company hopes to develop the technology for refurbishing parts that wear or erode under normal operating conditions of the engine. It’s part of an overall strategy to integrate advanced technologies into P&W’s aftermarket offerings.

Earlier this year the firm announced an expansion of its technology accelerator programmes focused on digital inspection, additive processing and advanced coatings for critical engine parts. Together, they are expected to derive annual savings of at least $24 million when fully rolled-out.

The North American facility complements a similar technology accelerator established in Singapore in 2022, which focuses on robotics, advanced inspection, connected manufacturing systems, and digital twin applications. Both centers support upgrades to maintenance capabilities across P&W’s global service network, which includes 20 MRO shops across four continents.

Read more : Horizon Microtechnologies Proves Copper Coatings Are Highly Durable

Other aerospace firms have also been considering creative repair options. GE Aerospace had in 2022 become the first to secure approval for metal 3D printing of repair parts for commercial jet engines, at its Loyang plant in Singapore.