Josef Prusa is at it again, delivering what fans have been clamoring for: a blazing fast CoreXY 3D printer to compete with Bambu Lab and the growing army of Voron clones flooding the market. The new CORE One arrives with an impressive design that doesn’t just impress – it shares DNA with the popular MK4S, to the point where Prusa is offering a $450 conversion kit for existing owners.

Prusa enthusiasts have been begging the European manufacturer to produce a CoreXY ever since they revealed their industrial Pro AFS (Automatic Farm System) years ago. That impressive setup featured nine CoreXY printers working in harmony, proving the company had the chops to move beyond traditional bed slingers.

Shockingly, the CORE One doesn’t reinvent the wheel. Instead, it’s built with practicality and longevity in mind – no parts are welded or glued, and the entire machine can be assembled with basic tools. The steel exoskeleton frame isn’t just for show; it provides exceptional rigidity that Prusa claims is virtually indestructible. We’ll dig deeper into the design later in this review.

The CORE One isn’t meant to replace the MK4S, but rather offers a compelling alternative for makers who need an enclosed printing environment. While maintaining a similar footprint and build volume as Prusa’s classic bed slinger, it takes up significantly less space than an MK4S with an aftermarket enclosure. It’s also about 20% faster and features a cleverly designed chamber that can reach 55°C for engineering materials or maintain temperatures below 30°C for PLA. This means the door can stay closed regardless of material – a critical safety feature for homes with children or classroom environments.

The price tag sits at $1,199 for the assembled version, just $200 more than the MK4S. Budget-conscious buyers can opt for the kit version at $949, while current MK4S owners can upgrade for $449. The Prusa CORE One lives up to the company’s reputation for quality and reliability, earning it a spot among the best 3D printers we’ve tested this year.

Prusa CORE One: Key Specifications

| Specification | Details |

|---|---|

| Price | Assembled: $1,199 / Kit: $949 |

| Build Volume | 250 × 220 × 270 mm (9.8 × 8.6 × 10.6 in) |

| Printer Design | Enclosed CoreXY with all-steel exoskeleton frame |

| Chamber Temperature | Up to 55°C with active temperature control |

| Extruder | Nextruder with 360° cooling, direct drive system |

| Nozzle | High-flow Prusa Nozzle brass CHT – 0.4 mm |

| Maximum Temperatures | Nozzle: 290°C / Heatbed: 120°C |

| Print Surface | Magnetic heatbed with removable PEI spring steel sheets |

| Connectivity | Ethernet, Wi-Fi (optional module), USB drive |

| Calibration | Fully automatic first-layer calibration with Load Cell sensor |

| Compatible Materials | PLA, PETG, Flex, PC, ASA, ABS, Nylon, and more |

| Expandability | MMU3 compatible, optional camera, filtration system, and GPIO hackerboard |

Prusa CORE One Design Overview

The CORE One is a beautiful beast built around an all-steel exoskeleton frame that provides exceptional rigidity. This isn’t just marketing speak – the solid construction is immediately apparent when you see and touch this machine. The fully enclosed design features a glass door and top cover, creating a chamber capable of reaching up to 55°C for printing demanding materials.

Size-wise, the CORE One takes up 50% less space than Prusa’s MK4S inside an enclosure, measuring 415×444×555 mm (16.3×17.5×21.8 inches) while delivering an impressive 30% increase in print volume. The build area is a generous 250×220×270 mm (9.8×8.6×10.6 inches), making it suitable for most practical applications without hogging your desk space.

The motion system uses linear rails for X-axis and linear rods for the Y-axis, and a heavy-duty three-lead screw system for Z-axis. This allows for both precision and speed, the CoreXY kinematics allowing for lightning-quick moves сwithout compromising on quality. The printer can easily reach print speeds of 200mm/s with standard filaments and push beyond that with high-flow materials.

One of the standout design features is the clever integration of the enclosure with the printer’s structure. Unlike some competitors that just attach panels to a stock frame, the CORE One’s enclosure is part of the machine as a whole, making it more stable, not an afterthought. The doors open a full 180 degrees, making it easy to access the print bed even in tight spaces.

The Nextruder extruder system is a direct drive unit featuring a planetary gear system with a 10:1 gearbox ratio, allowing for precise filament control while maintaining enough torque for flexible materials. The 360° cooling system ensures proper part cooling from all angles, enabling those impossible overhangs that would fail on lesser machines.

What’s Inside the Prusa CORE One Box

Unboxing the CORE One is like Christmas morning for 3D printing enthusiasts. The massive package contains everything you need to start printing immediately, neatly organized and protected by custom-cut foam inserts.

For the assembled version, the printer comes fully built and tested, requiring minimal setup. The kit includes:

- The fully assembled Prusa CORE One printer

- A removable smooth PEI spring steel print sheet

- A 1kg spool of Prusament PLA in Galaxy Black

- A USB drive loaded with test prints and software

- A detailed 3D Printing Handbook

- Maintenance tools including hex wrenches, an acupuncture needle for nozzle cleaning, and alcohol wipes

- Power and ethernet cables

- A Wi-Fi module for wireless connectivity

- A color touchscreen interface

- And yes, Prusa’s signature gummy bears

The kit version contains all the same components, but requires assembly. The inclusion of a full kilogram of quality filament is a nice touch that lets you start printing immediately without additional purchases. The smooth PEI sheet provides excellent adhesion for most materials, though you might want to consider adding a textured sheet for materials like PETG.

Putting Together the Prusa CORE One

If you opt for the assembled version, setup is almost trivially simple. After lifting the printer from its packaging (which is a two-person job given its 22.5kg weight), you simply need to mount the color touchscreen to the front of the machine using the provided screws, place the PEI spring steel sheet on the magnetic bed, and connect the power cord.

For kit builders, Prusa’s legendary assembly instructions make the process straightforward, if time-consuming. Unlike some manufacturers who provide vague diagrams and expect you to figure things out, Prusa’s pictorial guides are detailed down to the smallest fastener, with 1:1 scale drawings to help identify parts. The kit assembly tests patience and basic mechanical skills, but it’s a great way to learn how 3D printers work, which pays off during later troubleshooting or upgrades.

The initial setup process involves inserting the included USB drive, which contains the latest firmware. The printer walks you through language selection and printer identification, then updates itself automatically. The process is refreshingly simple compared to some competitors that require multiple firmware flashing procedures before first use.

How to Level the Prusa CORE One

Bed leveling on the CORE One is almost magical compared to the manual procedures required on budget printers. Thanks to a sophisticated load cell sensor integrated into the print head, the machine can precisely measure its distance from the print bed across multiple points.

Upon initial setup, the printer runs through a self-test and calibration sequence that checks every component and calibrates the bed automatically. The load cell directly probes the print surface, measuring the exact distance at multiple points to create a detailed mesh of the bed topology.

What’s particularly impressive is that the Z-offset (the critical distance between nozzle and bed) is automatically set during this process. The printer performs a “first layer calibration” where it prints a zig-zag pattern while dynamically adjusting the nozzle height until it achieves perfect adhesion. This eliminates the frustrating paper-feeler-gauge dance that plagues many other printers.

The best part? This calibration retains its accuracy over multiple prints. You won’t need to recalibrate before every print job unless you’ve changed the print surface or made significant modifications. For those who’ve spent hours tweaking bed screws on lesser machines, this feels like science fiction.

Loading Filament into the Prusa CORE One

Filament loading on the CORE One is straightforward and largely automated. The machine features dual filament sensors that detect both the presence of filament and its movement during printing, providing early warning of any feeding issues.

Dual filament sensors in the machine can detect if filament is to be fed into the nozzle, and also if filament is moving during printing, giving early warning of any feeding issue. After bringing the nozzle up to temperature, the printer guides you to insert the filament into the extruder inlet until you feel the gears grab it.

The Nextruder system then automatically feeds the filament through the hotend, purging any previously loaded material. The purge process is thorough, ensuring complete color changes without contamination. When it’s time to unload, the process works in reverse, with the printer heating the nozzle before smoothly extracting the filament.

For those upgrading to the optional MMU3 multi-material unit (which supports up to five different filaments), the loading process becomes even more automated, with the system handling filament changes during printing. While the MMU3 kit specifically designed for the CORE One hasn’t been released yet, Prusa has confirmed compatibility with future updates.

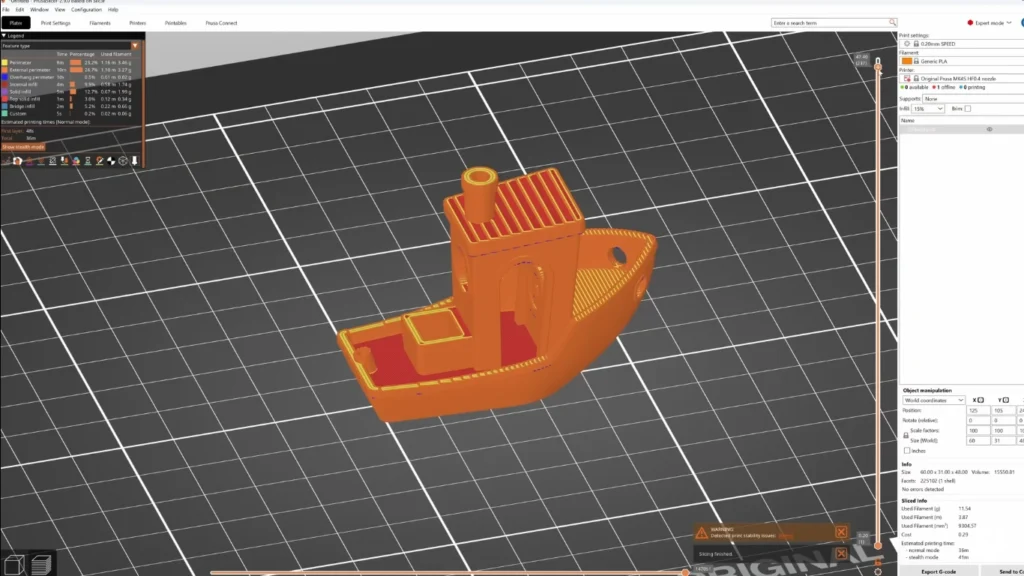

File Setup & Software for the Prusa CORE One

The CORE One works seamlessly with Prusa’s excellent slicing software, PrusaSlicer. This open-source program comes with factory-tuned print profiles for more than 200 different filaments, so you can avoid hours of tweaking and still get great results.

PrusaSlicer offers three complexity levels – Simple, Advanced, and Expert – allowing beginners to start with minimal options while giving experienced users access to hundreds of parameters. The software comes pre-configured with profiles specifically calibrated for the CORE One, leveraging its CoreXY kinematics and Input Shaper technology for maximum speed without quality loss.

Setting up a print is remarkably simple. Import your 3D model, select your material and quality settings, and slice. The software automatically generates appropriate supports, infill, and cooling based on the model’s geometry. More advanced users can dive into custom settings for specific requirements, but the defaults work exceptionally well for most applications.

What truly sets the ecosystem apart is its integration with Printables.com, Prusa’s model repository containing hundreds of thousands of free 3D models. You can browse models directly within PrusaSlicer or on the website, then send them to the slicer with a single click. This eliminates the endless searching and downloading from multiple repositories that typically plagues the 3D printing workflow.

For remote management, Prusa Connect offers cloud-based printer control, allowing you to monitor prints, queue jobs, and receive notifications from anywhere. The system integrates with both PrusaSlicer and the new Prusa App for iOS and Android, creating a seamless ecosystem for printer management.

Connectivity options are plentiful. The CORE One includes both Ethernet and optional Wi-Fi (included with the printer), allowing for network integration. Setting up Wi-Fi is remarkably simple thanks to NFC – just tap your phone to the back of the printer, and the connection details transfer automatically. For security-conscious environments, the machine can operate entirely offline, with firmware updates possible via USB drives.

Starting a Print on the Prusa CORE One

Once your file is prepared, starting a print couldn’t be easier. Transfer the sliced file to the printer via USB drive, network connection, or Prusa Connect, then select it from the print menu on the touchscreen.

Before each print, the machine conducts a fast nozzle cleaning procedure, ensuring that no gunked-up filament will ruin your print. It does this by purging a little filament at a corner of the bed, which sometimes leaves residue on the print surface that must be wiped clean.

The first layer is printed at a reduced speed to ensure perfect adhesion, with the machine leveraging its precise Z-offset calibration for consistently flawless results. Once the critical first layer is complete, the printer ramps up to full speed, with the CoreXY system gliding silently through complex movements.

With the enclosure closed, the CORE One operates at impressively low noise levels – typically in the mid to high 40dB range, occasionally reaching the 50s during rapid movements. This makes it one of the quietest printers we’ve tested, a good choice for home offices or any location in which noise would be an issue.

The print progress is clearly displayed on the touchscreen, with remaining time estimates that are surprisingly accurate thanks to Prusa’s extensive testing. If you’re using Prusa Connect or the mobile app, you’ll receive notifications at key points during the print process, including completion and any errors.

Latest News: Kimya Filaments Join Airtech’s Additive Manufacturing Line

Speaking of errors, the CORE One handles potential print failures gracefully. The dual filament sensors detect both filament runout and feeding issues, automatically pausing the print and alerting you. Power failures are also covered by the built-in power panic feature, which saves the print state and allows resumption once power returns.

Print Quality and Performance

The CORE One delivers exceptional print quality that rivals machines costing twice as much. Fine details come out crisp and clear, overhangs up to 75° print flawlessly thanks to the 360° cooling system, and layer lines are virtually invisible at 0.2mm layer height.

Speed is another area where this printer shines. Using the default settings, print times are already impressive, but enabling the high-speed profiles unleashes the CoreXY system’s potential. Complex models that would take 12+ hours on traditional printers finish in half the time without quality loss. The CHT high-flow nozzle allows for true flow rates up to 30mm³ per second, making short work of large solid parts.

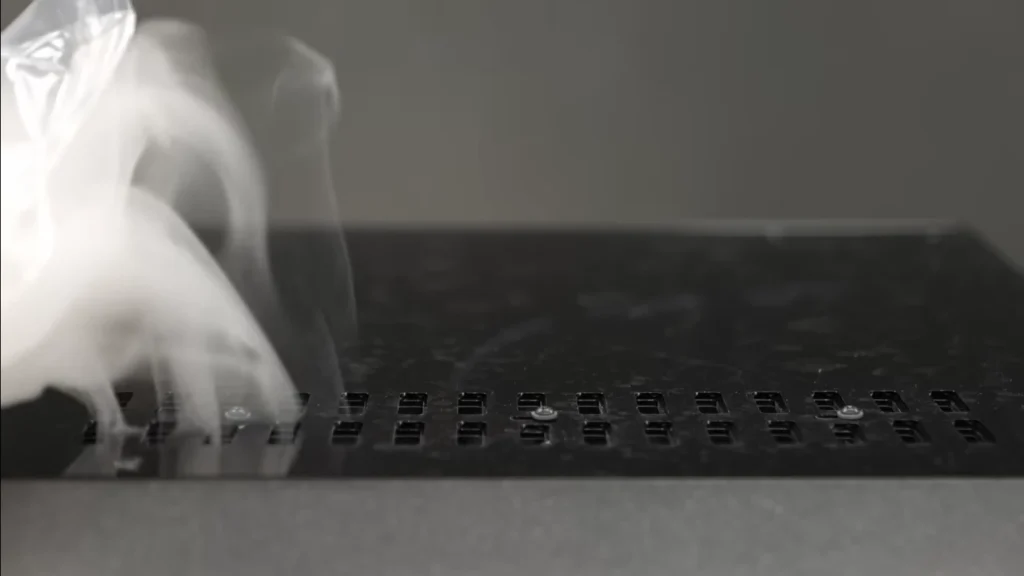

Excellent Material Versatility Basic filaments such as PLA and PETG print beautifully but that enclosed chamber also makes easy work of engineering materials such as ABS, ASA, PC, and nylon. The chamber temperature can reach 55°C with the bed heated, providing stable conditions for warp-prone materials. For PLA and TPU, the automatic ventilation system allows printing with the door closed, maintaining temperature stability without heat buildup.

The printer’s versatility extends to practical applications. Functional parts with tight tolerances fit perfectly, showing excellent dimensional accuracy. Cosmetic models showcase smooth surface finishes and crisp details. Even delicate structures with thin walls print reliably thanks to the direct drive extruder’s precise control.

Perhaps most impressively, the CORE One maintains this quality consistently from print to print. There’s no gradual drift requiring recalibration or tweaking – it just works, print after print.

Expandability and Future-Proofing

Prusa designed the CORE One as a platform rather than a one-off product, and its modularity shines in this regard. Everything can be taken apart with basic tools, making maintenance and upgrades straightforward.

The optional accessories already announced include a high-resolution USB-C camera (Buddy3D $39.99) for print monitoring, an advanced filtration system for capturing ultrafine particles and fumes, and a GPIO hackerboard for controlling external devices. More accessories are in development, including different filtration options and a drybox for moisture-sensitive filaments.

The printer’s compatibility with existing Prusa components adds value for current users. The CORE One uses many MK4S parts, including print sheets, nozzles, and hotends. For MK4/S owners looking to upgrade, Prusa offers a conversion kit to transform their printer into a CORE One, preserving their investment.

Software support is equally forward-looking. Prusa’s commitment to open-source development means regular firmware updates add features and improvements long after purchase. The company has a proven track record of supporting their printers for years, with even decade-old models receiving updates and upgrade paths.

Conclusion

The Prusa CORE One is a near-perfect machine and exactly what the company needed to stay competitive in today’s high-speed printing marketplace. While it lacks a few bells and whistles like a built-in camera, Prusa’s legendary reputation for reliability and long-term support makes this a smart investment that will remain relevant for years to come.

At $1,199 for the pre-assembled version and $949 for the DIY kit, the CORE One isn’t targeting the budget segment, but it’s unquestionably one of the best options a newcomer could start with. The integrated enclosure and accessible spool holder, combined with the seamless Prusa Connect ecosystem, make it ideal for print farms running engineering materials. It’s also perfectly suited for educational settings, with an enclosed design that keeps curious fingers away from hot components while still handling basic PLA prints with ease.

For tinkerers who already own an MK4S, the $450 conversion option is a compelling way to upgrade to CoreXY performance at a significant discount. The future compatibility with the MMU3 multi-material system promises to add five-color printing capability, further extending the machine’s versatility.

If the Prusa price tag stretches your budget a bit too far, the Bambu Lab P1S Combo remains our top recommendation for accessible color printing at $829 with the AMS included. For those needing more build volume with similar speed, the Creality K2 Plus Combo delivers Core XY performance with four-color capability for $1,499.

One Response