AI system dramatically improves how metal parts are 3D printed, reducing costs and enhancing quality.

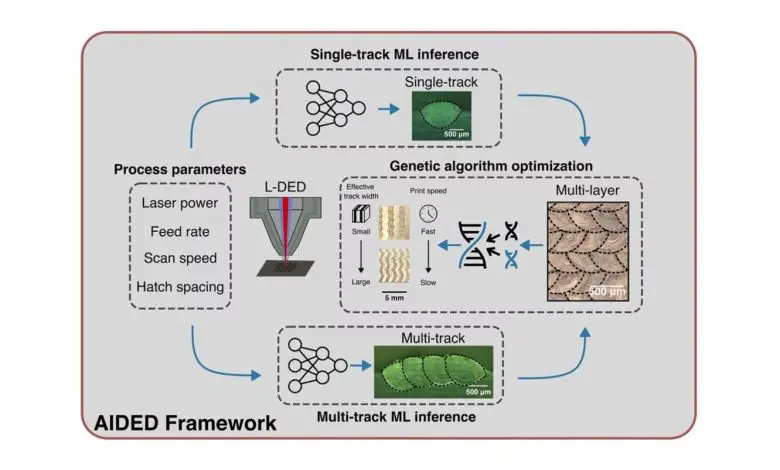

In 2023, researchers at the University of Toronto Engineering unveiled a new machine learning framework that’s changing the game for metal 3D printing. Led by Professor Yu Zou, the team developed what they’ve dubbed AIDED (‘Accurate Inverse Process Optimization Framework in laser-Directed Energy Deposition’), which addresses long-standing challenges in additive manufacturing.

Metal 3D printing isn’t an inexpensive process, and one of the goals for the AIDED framework was to reduce operating costs and create better quality parts across the board. Finding the optimal printing conditions traditionally required extensive trial and error, but this new approach uses sophisticated AI to identify the perfect parameters in a fraction of the time.

One smart way to optimize printing is through machine learning. But this isn’t your hobbyist level AI.

Minnesota-based Stratasys specializes in “additive manufacturing,” the process of creating an object by building it one layer at a time. The term is synonymous with 3D printing. However, the industry often reserves that description for hobby-level projects on smaller, non-industrial printers, while additive manufacturing represents robust industrial solutions.

Not long ago, the standard procedure for optimizing 3D printing parameters was conducted through extensive trial and error, which Zou’s team says is more limiting than their AI-driven process.

“We have demonstrated that our framework can identify optimal process parameters from customizable objectives in as little as one hour, and it accurately predicts geometries from process parameters,” said Xiao Shang, PhD candidate and first author of the new study. “It is also versatile and can be used with various materials.”

The kind of system Zou’s team builds isn’t the type you’d find in a typical research lab, either. AIDED operates in a closed-loop system where a genetic algorithm first suggests parameter combinations, which machine learning models then evaluate for printing quality. This sophisticated approach allows them to quickly determine the perfect conditions for different materials and components.

Last year, traditional manufacturers had to spend weeks or even months finding the right parameters for new parts. Designed digitally in complex computer models, the entire printing process was subject to numerous variables that could affect quality.

The bet on machine learning paid off. The researchers’ work was published in the journal Additive Manufacturing, earning recognition for its potential to transform manufacturing across industries.

The next frontier in 3D printing

In the past few months, Zou’s team has been pushing the technology even further, working on an enhanced autonomous additive manufacturing system that operates with minimal human intervention, similar to how autonomous vehicles drive themselves.

Competition for this market continues to heat up, however, as there are startups and legacy companies pushing hard. Around the world, AI-driven manufacturing solutions abound.

The University of Toronto team has one major factor on its side: the ability to quickly adapt to different materials and printing conditions. What’s new is that today’s AI-optimized printing is more accurate, it’s faster, and the output is more robust, Shang says.

“I think what’s changed drastically over the past few years has been all about data collection and processing,” he explains. “We’re seeing results that are just incredible, whether it’s how resistant to heat the parts are or how strong they are compared to how much they weigh.”

He expects the next frontier to be all about autonomous manufacturing, or how quickly systems can adapt without human intervention.

“If you need hundreds of different types of components, you don’t want to optimize each one manually,” Shang says. “You want a system that can learn and adapt on its own. How quickly can you optimize a process that is still accurate, still strong, all the other things that the customer cares about, but faster?”

Industries like aerospace and healthcare clearly care about precision on all fronts, and AI-enhanced 3D printing allows manufacturers to quickly test and create new components. Zou tells the story about how their framework identified a set of parameters that looked perfect on paper but didn’t produce the expected results. As a result, the team was able to fine-tune their models to account for previously unknown variables.

In the past, the worst case scenario might have been to adjust parameters manually until finding something that worked. But more likely, manufacturers would be required to conduct hundreds of test prints, which would have meant a lot of wasted materials and energy. It’s very expensive and requires skilled labor and time, a scarce commodity.

“The thing that manufacturing never has is extra time,” Shang says.

Many of the advantages Zou’s team is developing relate to precision. Material flow direction is incredibly important, as some parts at certain times need specific internal structures to prevent warping and cracking. Material is also directed precisely to create complex geometries. Sometimes material properties need to be optimized for strength. And sometimes parts need to be lightweight while maintaining structural integrity.

“It’s better, faster, cheaper,” Shang says. “It’s faster to optimize with AI than to do it manually, and then it’s certainly cheaper in a multitude of different ways. Number one, there’s not as much skilled labor required for AI-driven optimization as there is in traditional parameter finding methods.”