NYU researchers pioneer commercial 3D-printed syntactic foam, revolutionizing manufacturing for underwater and aerospace applications.

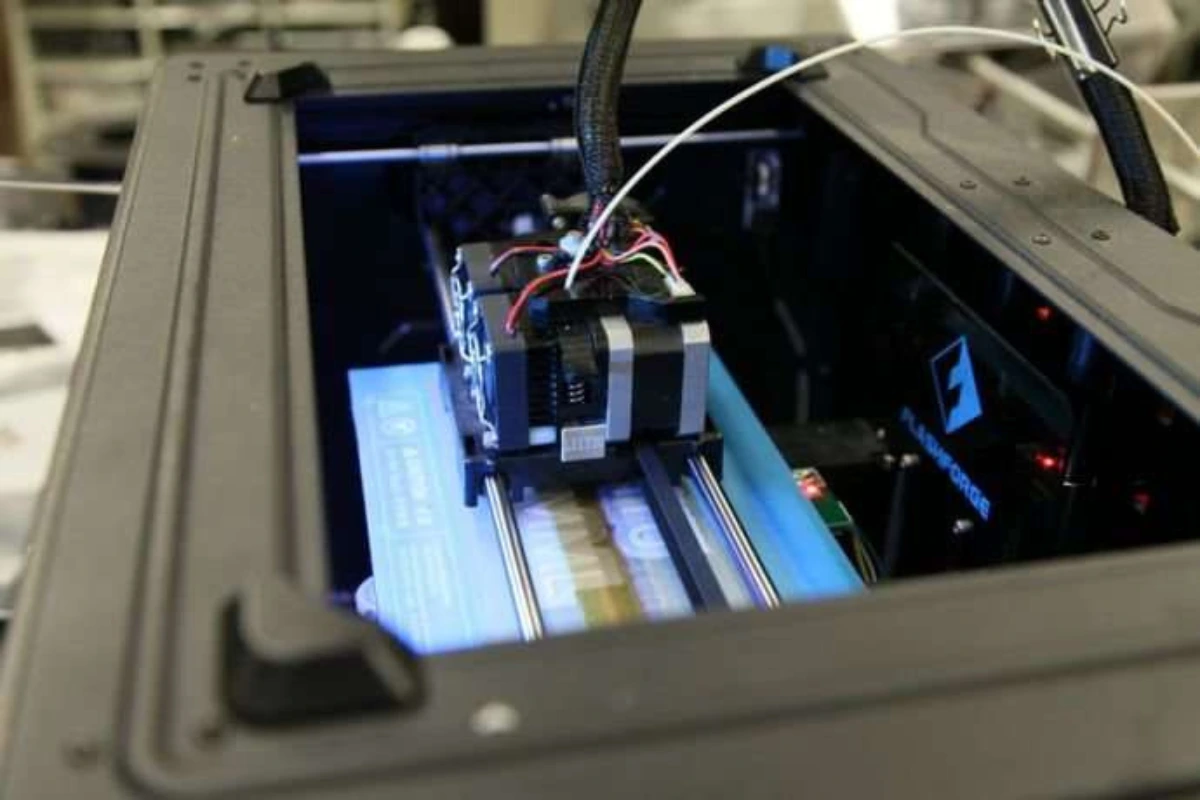

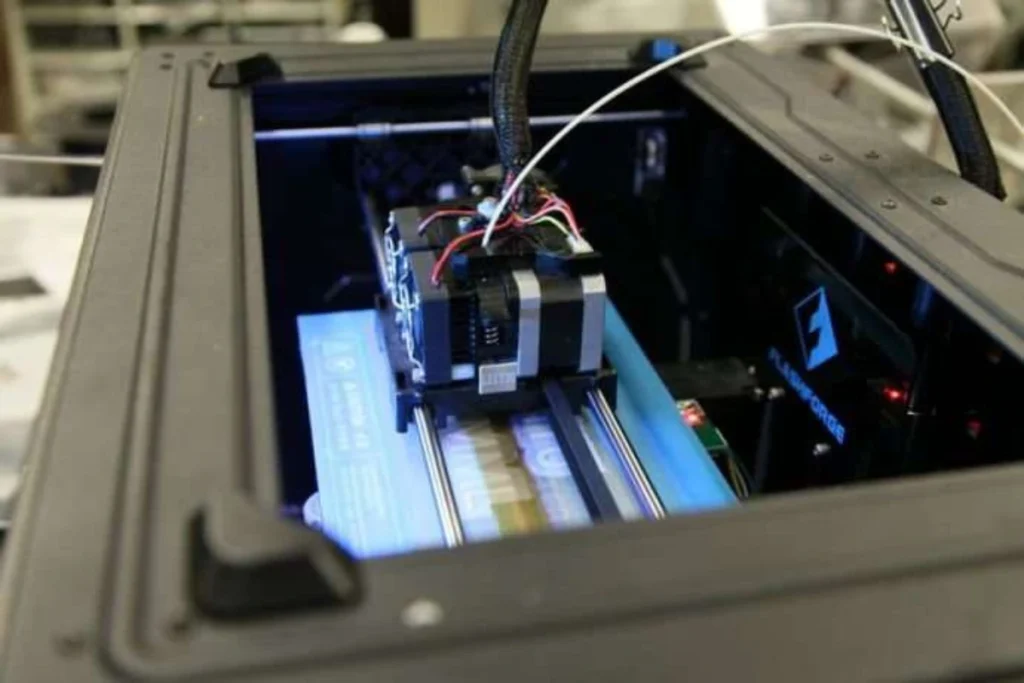

In what may be the most noteworthy advancement likely to change underwater exploration and industrial level manufacturing, researchers from NYU Tandon School of Engineering have developed a method for 3D printing syntactic foam, an super lightweight and ultra durable material, using a commercial grade printer. The breakthrough is expected to be accomplishable on regular commercial grade printers because of the work done by Nikhil Gupta, the mechanical engineering professor who leads the research. This will drastically increase the attainable performance of the material, which has for decades been used in specialized applications such as deep sea submersibles and even in the aerospace industry.

From Lab to Mainstream: Reinventing a Legacy Material

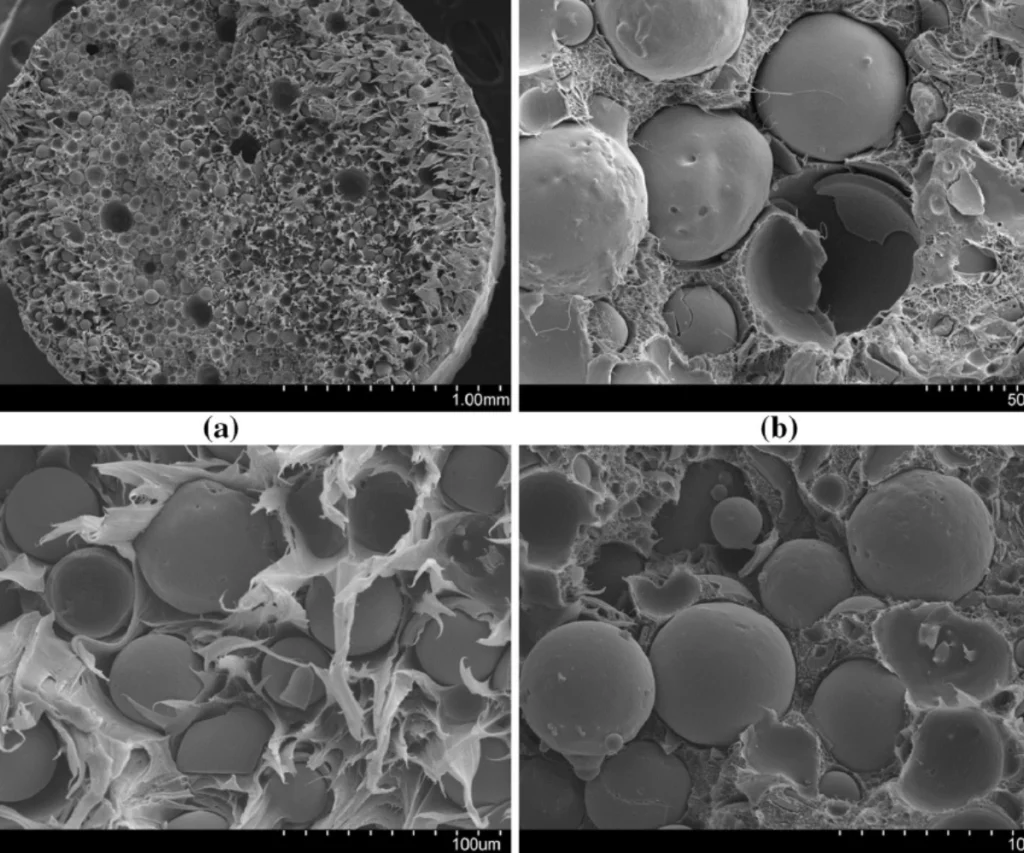

Syntactic foam first made in 1955 by the Bakelite Company is a composite plastic filled with microscopic hollow spheres. These “microballoons” give the material remarkable strength-to-weight ratios and resistance to extreme pressures and temperatures. It has been used in everything from James Cameron’s record-breaking Deepsea Challenger submersible, which traversed depths of six miles in 2012, to aircraft components and sports equipment. Unfortunately, conventional manufacturing techniques depend on injection molding, restricting design complexity followed by labor-intensive construction of multi-component assemblies.

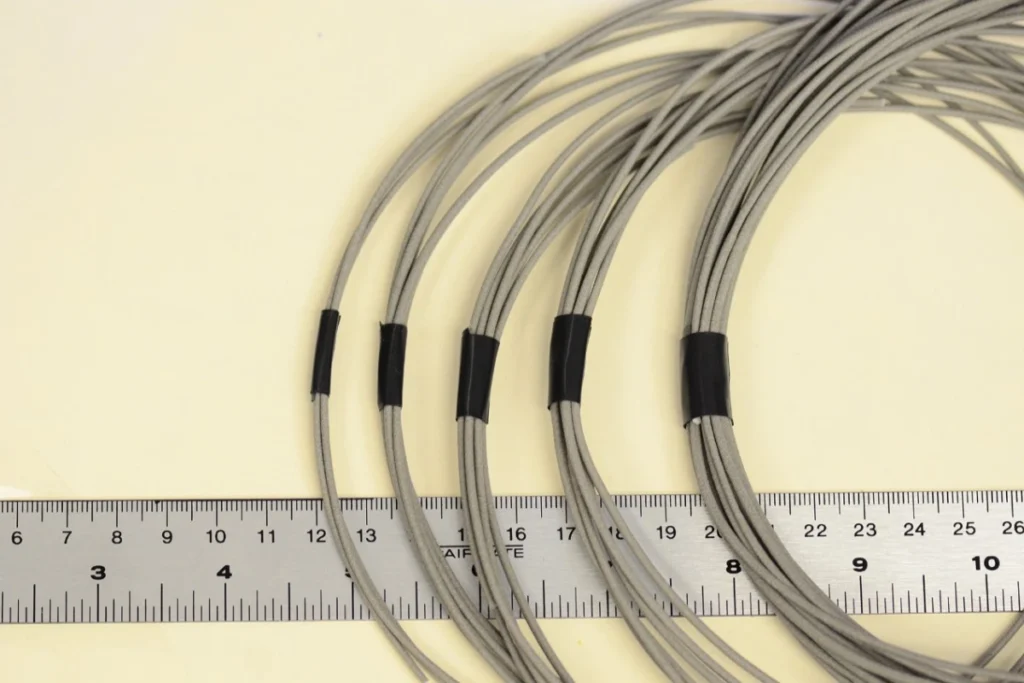

Gupta’s crew has broken through these limits by modifying synthetic foam for commercial 3D printers. “Our objective was to develop a filament that can be used with off-the-shelf machines no expensive upgrades,” Gupta said. The accomplishment relies on a new polyethylene-based filament, laced with hollow glass microspheres (an average of 40 microns in diameter) and fly ash, a residue from burning coal. The mixture slashes materials costs without sacrificing structural integrity, paving the way for hobbyists, researchers, and industries to prototype and produce complex designs in a single print.

Overcoming Technical Hurdles

Developing the filament was far from straightforward. Early challenges included microsphere breakage during extrusion, nozzle clogging, and uneven distribution of particles. The team tackled these issues through meticulous engineering: optimizing nozzle size (1.7mm), adjusting extrusion temperatures, and designing a proprietary extruder now patent-pending to prevent microsphere damage.

“Smaller microspheres were key,” Gupta noted. “Larger ones fractured during mixing, but 40-micron spheres survived the process, maintaining the foam’s lightweight properties.” The final filament contains 40% microspheres by weight, striking a balance between strength and printability.

Printing parameters also required precision. The build plate’s thermal expansion coefficient had to match the filament to minimize warping, while extrusion speed and temperature were fine-tuned for consistency. “Most printers allow these adjustments, so scalability isn’t an issue,” Gupta added.

Applications: From Deep Sea to Outer Space

The implications are vast. For submersibles, 3D-printed syntactic foam could reduce the time needed to produce hulls that can withstand high pressures or serve as filling material for more compact parts, allowing longer, deeper missions. Automotive firms might use it to produce lightweight, fuel-sipping parts, and aerospace specialists could print satellite casings that can withstand heat. Even consumer goods rugged sports gear, for example could gain.

Gupta emphasized the environmental angle: using fly ash, a waste product, aligns with circular economy goals. Collaborators in India are already exploring additional sustainable materials, including recycled plastics.

Future Frontiers: Nanotubes and Custom Microspheres

Research in the next phase will seek to improve the foam’s properties with the incorporation of nanofillers such as carbon nanotubes and engineered air bubbles. The team is also studying microspheres created from metals, ceramics, and polymers and varied sizes, wall thicknesses, and coatings to perform differently. “Think of microspheres with flame-retardant chemicals for aerospace or oil-absorbing stuff for cleaning oil spills,” Gupta said.

Read more : Ceramic 3D Printing Holds Promise but Faces Adoption Challenges

A New Era of Accessibility

By eliminating reliance on costly injection molds and specialized printers, NYU’s innovation lowers barriers for small businesses and academic labs. A student could theoretically design and print a mini-submarine hull in days, a process once requiring months of fabrication.

“This isn’t just about better materials it’s about empowering creativity,” Gupta remarked. “We’re turning decades-old science into something anyone with a $500 printer can use.”

As industries race to adopt additive manufacturing, Gupta’s syntactic foam could emerge as a linchpin for next-gen engineering proving that sometimes, the deepest breakthroughs begin in the lab.