Stratasys launches the Neo800+ 3D printer, offering up to 50% faster production speeds for large-scale automotive and aerospace components.

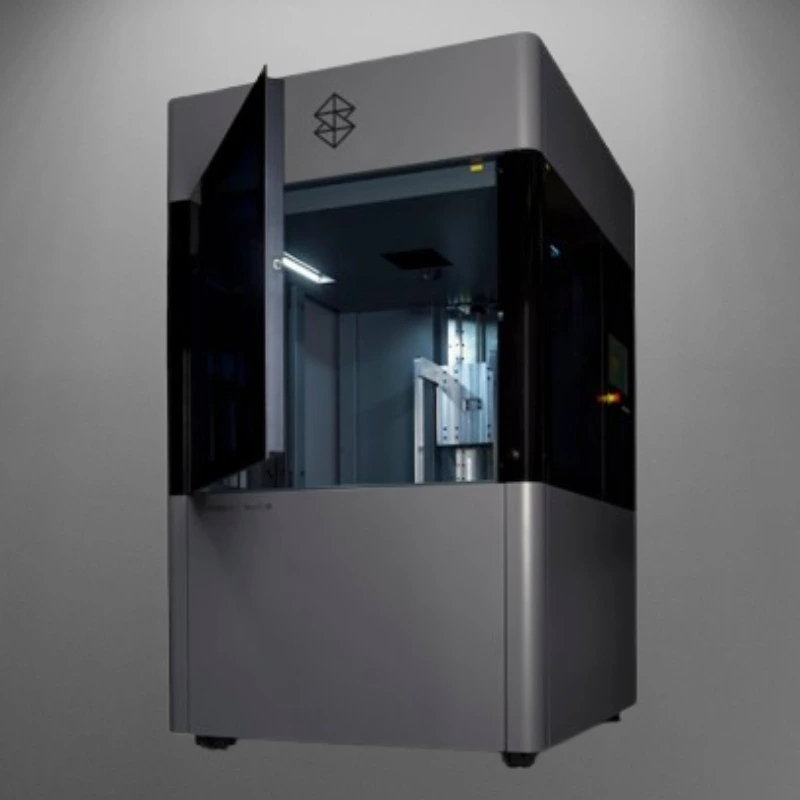

The Neo800+ 3D printer has officially been unveiled by Stratasys and is designed for high volume industrial manufactuing in aerospace, automotive, and industries such as manufacturing with a modernized approach that should help expedite production pace by 50%. This enhanced device was revealed on Tuesday at the Additive Manufacturing Users Group Conference in Chicago. It aims at precision demanding sectors that require high-efficient prototyping, tooling, and even mass manufacturing of end-use components.

Neo800+ utilizes Stratasys’ proprietary technology named as ScanControl+ which increases the efficiency of laser scanners, reducing the time-to-part by around 39% on average, and for some applications such as tooling molds, the percentage goes as high as 44%. In addition, the newly proposed optics along with the laser’s configuration makes ways to new advanced materials to be used like the most recently proposed Somos WaterShed XC+ resin which is designed to rapidly cure and deliver crystal clear smooth surfaced output

“The speed upgrades allow us to meet tighter deadlines without sacrificing quality,” said Sean Schoonmaker, Director of Operations at Stratasys Direct Manufacturing. “Surface finishes are so refined that post-processing time drops significantly, and part accuracy remains consistently within tolerances.”

Apart from speed, the Neo800+ offers features geared toward improving dependability: Vacuum System Protection optimizes resin usage, Z-Stage Collision Detection safeguards equipment, and environmental sensors guarantee printing stability. The objective is to minimize operational expense and equipment idle time in industries like automobile racing that have clients such as McLaren and Team Penske who need rapid prototyping.

Read more : 3D Printed Bike Helmet Offers Better Protection With Unique Design

Developed from technology acquired via UK-based RPS in 2021, the Neo series has already gained traction with supercar manufacturer Briggs Automotive Company and service providers like Ogle Models. Stratasys plans to formally launch the Neo800+ at the RAPID + TCT expo in Detroit on April 8, with Rivian Automotive representatives joining the showcase.

Priced competitively for large-format additive manufacturing, the Neo800+ underscores Stratasys’ push to dominate high-speed production markets. Early adopters praise its ability to streamline workflows for wind tunnel components, jigs, and fixtures critical for sectors where delays equate to lost revenue.