Researchers discover crystalline structure significantly improves 3D printing strength using lunar materials.

Researchers at the University of Toulouse have discovered that the structural composition of lunar regolith significantly affects 3D printing strength, according to a paper published in Acta Astronautica.

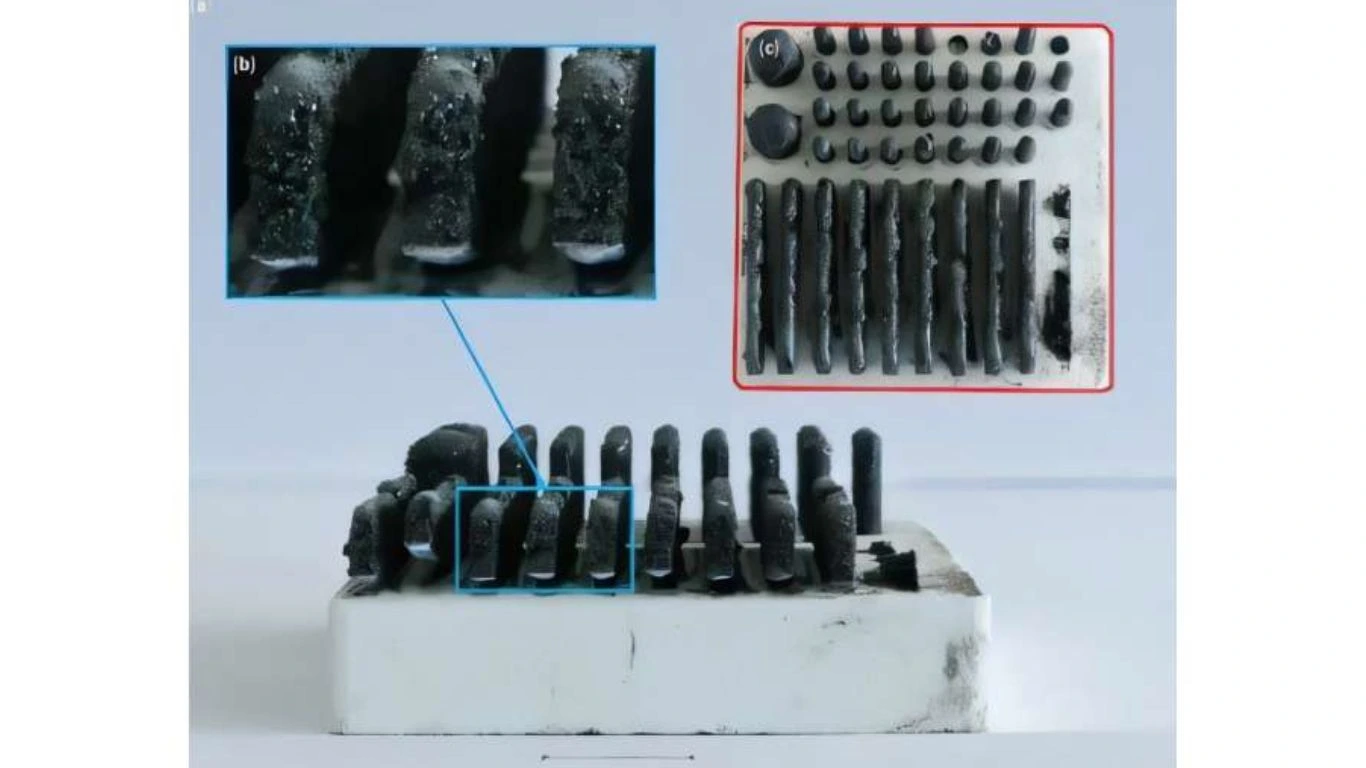

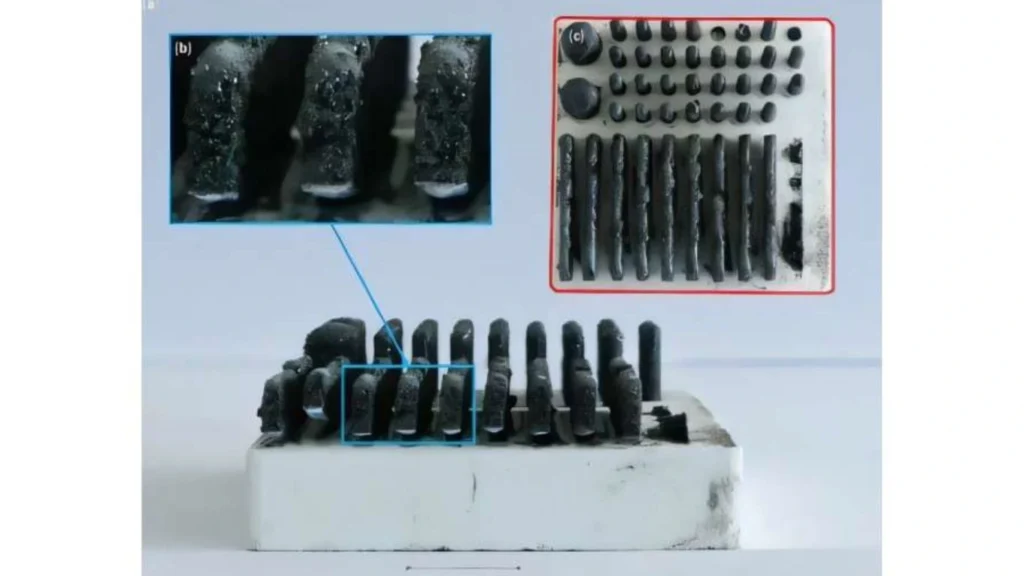

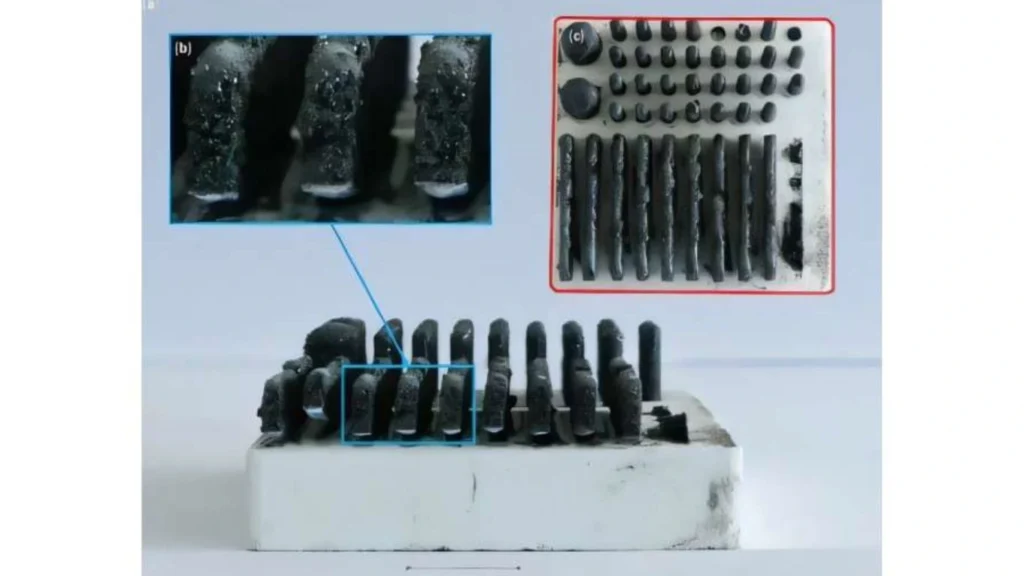

The study tested selective laser melting on a lunar regolith simulant called Basalt of Pic d’Ysson (BPY), a volcanic rock from France that closely resembles moon rocks.

Tests revealed that regolith with 100% crystalline structure produced double the compressive strength compared to 100% amorphous structure. The crystalline samples reached 4.2 MPa, comparable to standard masonry bricks, despite having nearly 50% porosity.

Most previous 3D printing attempts with lunar regolith required binding agents shipped from Earth, increasing mission costs. This research focused on using only the regolith itself as building material.

“We wanted to eliminate the need for Earth-sourced materials,” said Dr. Julien Garnier, who led the research team.

The BPY regolith simulant has been used in other studies, including ESA’s “solar sintering” technique and Project MOONRISE’s zero-gravity applications, but compression strength has remained a challenge.

The research team plans to further optimize the mix between crystalline and amorphous structures, as well as refine particle size and processing parameters.

Read more : Cambridge Scientists Unlock Infinite Energy From Sunlight

These discoveries are significant for the progress of preparing for the humans’ return to the lunar surface, where one day astronauts could build structures using the moon’s resources.