Renishaw’s TEMPUS technology revolutionizes additive manufacturing with up to 50% faster build times, enhancing productivity for RenAM 500 systems.

Renishaw’s TEMPUS Boosts Metal AM Efficiency, Reducing Build Times by Up to 50%

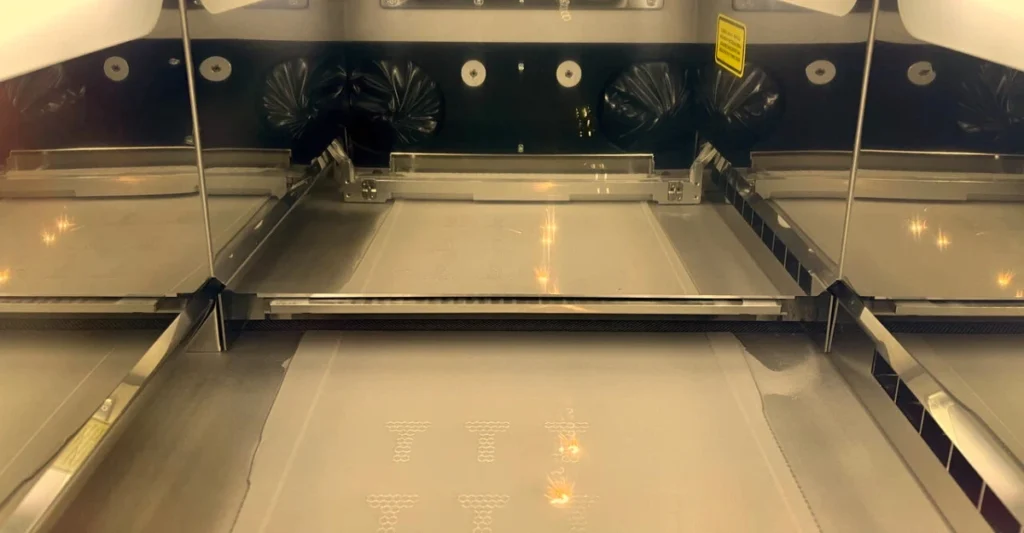

An annex of an UK based engineering group Renishaw has tempers technology which is set to revolution the metal additive manufacturing industry. The TEMPUS technology promises to reduce build times by 50% for the users of the RenAM 500 series. In comparison to previous methods where lasers were operated separately from the recoater, during coating phases separated by idle times, TEMPUS technology gives room for synchronizing laser operations with recoater movements. Such advancements significantly improve the feasibility of using additive manufacturing for high-volume industrial applications while ensuring exceptional part quality standards.

How TEMPUS Works: Eliminating Downtime, Maximizing Output

Traditional powder bed fusion systems require a sequential process: the recoater spreads powder across the build plate, pauses, and then lasers consolidate the material. TEMPUS disrupts this workflow by enabling simultaneous recoating and laser sintering, trimming up to nine seconds per layer. For complex, multi-layered components, this translates to time savings of “tens of hours” per build, according to Renishaw. Components with thin, vertical structures—common in aerospace and medical devices—benefit most, achieving up to 70% faster cycle times in some cases.

“TEMPUS is one of our largest developments in recent years,” said Chris Dimery, AM Business Manager EMEA at Renishaw, in an interview with 3D Printing Industry. “By reducing machine time per part, we’re directly addressing the dominant cost factor in AM: production time.”

Upgrades for Existing Users and New RenAM 500 Ultra System

Existing RenAM 500 series customers can integrate TEMPUS through a paid upgrade, ensuring they maximize their current investments. Meanwhile, Renishaw’s newly launched RenAM 500 Ultra system incorporates TEMPUS alongside enhanced optical systems, advanced gas-flow designs, and real-time process monitoring software. The Ultra model, available in single-laser (500S) or quad-laser (500Q) configurations, targets industries requiring high-throughput production of intricate geometries, such as automotive and energy.

Louise Callanan, Director of Additive Manufacturing at Renishaw, emphasized the broader implications: “The time and cost savings from TEMPUS and the RenAM 500 Ultra will expand AM’s role in mass production. Manufacturers can now achieve full-scale output at the lowest cost per part.”

Collaborations Highlight Real-World Impact

Renishaw’s partnerships underscore TEMPUS’s practical value. Metal component specialist Alloyed, an early adopter since 2021, has leveraged the technology to streamline production of aerospace parts. Similarly, Cookson Industrial, a UK-based leader in precious metal AM, adopted Renishaw’s RenAM 500S Flex system to optimize 3D printing of platinum-rhodium components—critical for high-temperature applications like glass manufacturing. With platinum-rhodium priced at approximately £80,000 per kilogram, minimizing waste through precise laser control is economically transformative.

In the U.S., Connecticut’s Mott Corporation integrated the RenAM 500S Flex into its workflow, slashing machine setup times by over 50% and improving part consistency by 30%. “The system’s automation and precision have redefined our production capabilities,” a Mott spokesperson noted.

Showcasing Innovation at Industry Events

Renishaw debuted TEMPUS at the Additive Manufacturing User Group (AMUG) conference in Chicago (March 30–April 3) and will feature it at RAPID + TCT in Detroit (April 8–10). These events highlight the company’s commitment to advancing AM accessibility and scalability.

Read more : New 3D-Printed Heat Exchangers Offer Better Cooling Performance

The Future of AM: Faster, Cheaper, Smarter

With the aim of achieving environmentally friendly and economical production processes, TEMPUS now places Renishaw on the leading edge of AM innovation. The technology tackles the dual problems of time and cost, not only improving existing workflows, but also enabling new ones—besides custom medical implants, even airframe structures for aerospace may be manufactured. Renishaw’s unyielding amphasis on productive Additive Manufacturing demonstrates that this mechanical industry is maturing and no longer just a developmental aid.