UC San Diego researchers create cheap, electronics-free air-powered 3D-printed robots for tough environments such as disaster sites and space.

A New Era in Robotics: Electronics-Free Design

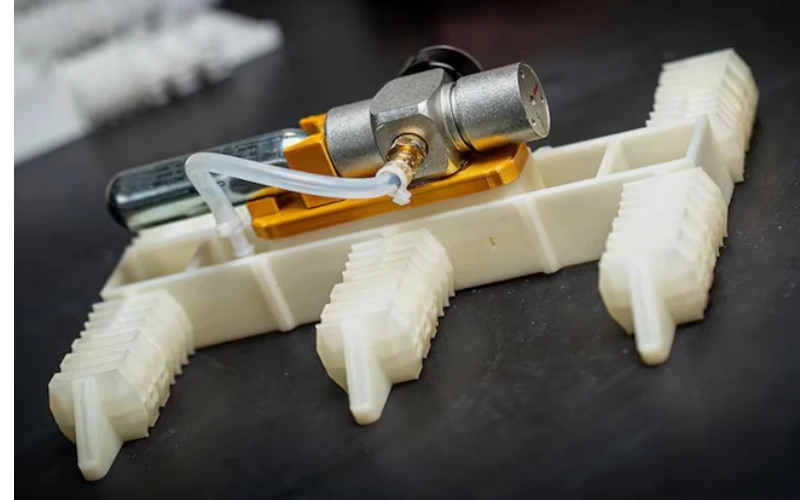

Researchers at the University of California San Diego have developed a six-legged robot that runs on no electronics, wiring, or complicated assembly. Compressed air is the only power source, and the innovation is 3D-printed in a single piece with flexible, low-cost materials. With a cost of only $20 per unit, the robots represent a radical break from conventional rigid designs, with a focus on simplicity, affordability, and versatility.

How It Works: Pneumatic Power and Precision

At the core of the robot’s movement lies a pneumatic oscillating circuit, inspired by steam engine mechanics. This system coordinates rhythmic leg motions by alternating air pressure between two sets of three legs. Each leg boasts four degrees of freedom, enabling up-down and forward-backward movements for steady, straight-line walking. “This reimagines how machines are built,” said Michael Tolley, a UC San Diego professor and senior study author. The robots emerge fully functional from standard 3D printers, requiring only a compressed gas cartridge to activate.

Testing and Versatility: From Labs to Extreme Environments

Lab trials demonstrated the robot’s endurance, functioning non-stop for three days when tethered to an air supply. Untethered outdoor tests proved even more impressive: the robots navigated turf, sand, and underwater environments using portable gas cartridges. Their electronics-free design makes them ideal for high-risk scenarios, including disaster zones, high-radiation areas, and space missions. “They’re robust, cheap, and built for extremes,” Tolley emphasized.

Read more : Sodick Strengthens Laser 3D Printing Capabilities with Prima Additive

Potential Applications: Rescue, Research, and Beyond

These machines would revolutionize industries that require ruggedness in harsh environments. Researchers can see themselves using them for search-and-rescue missions, monitoring the environment, or space travel. Their rugged yet soft body reduces damage risk on unfamiliar landscapes. Their simplicity reduces costs and time when making them.

Future Developments: Sustainability and Enhanced Functionality

Next-phase goals include integrating onboard gas storage and expanding capabilities. Plans involve using recyclable or biodegradable materials to boost sustainability, as well as adding grippers for tasks like debris removal or sample collection. The team also aims to scale the technology for larger robots or swarm-based systems. “We’re redefining robotics’ role in solving real-world challenges,” said lead researcher James Smith.