University of Washington researchers create innovative biodegradable 3D printing materials that actually become stronger when compressed.

The University of Washington has announced a breakthrough in 3D printing technology with materials that are not only environmentally friendly but also exhibit remarkable strength properties.

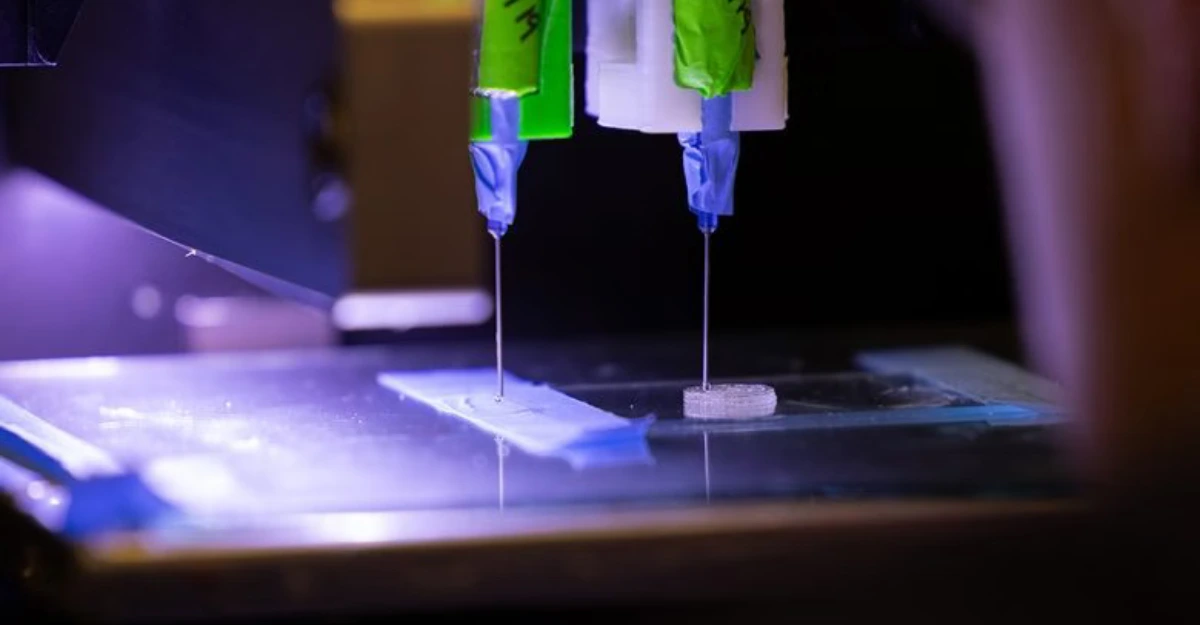

Chemistry professor Alshakim Nelson and his team at UW have developed biodegradable and sustainable 3D printing materials that become stronger when stressed, addressing a significant gap in the market for eco-friendly options with superior mechanical properties.

“We were looking for something that could be used as a 3D printable and biodegradable material, but that also had the necessary mechanical performance,” said Nelson, who is also in the NIST Faculty Fellows program.

The research combines custom bioplastics with innovative printing techniques. Undergraduate student Angus Berg, who works in Nelson’s lab, described the development process as “like cooking, except the ingredients are limitless.”

One of the team’s most significant innovations is a bioplastic that strengthens after compression. This unusual property results from a lattice structure co-designed with mechanical engineering professor Lucas Meza, allowing the material to absorb force without cracking – an advancement with potential applications in construction and medical devices.

Nelson, who arrived at UW in 2015 after a decade at IBM, has since begun working collaboratively with researchers across disciplines in engineering and medicine. Researchers are also working on 3D printed stents that can release anti-inflammatory agents into the body and have therapeutic materials that continually thrive over a year and can be kept on the shelf for six months.

“One of the neat things we learned is that these materials will be viable for years,” Nelson said. This durability paves the way for the localised, on-demand production of drugs, for example in the field of space travel. “Is this an operation that could be done in space? I think you can do it.” Nelson said in references to future NASA uses.

The UW team are also working to develop plant-based proteins to use for printing. “What we have just discovered is that we can 3D print using a protein from a genetically modified rice,” Nelson added. “It has some nice properties, and it can do some new things.”

Read more : TCP Bioceramic Implants Proven Effective in Jaw Treatments

From strengthening infrastructure to producing medicine in orbit, Nelson’s team is expanding the frontiers of what 3D printing technology can achieve while maintaining a commitment to sustainability.