Lumafield raises $75M in Series C funding to expand next-gen CT solutions, enhancing quality control in manufacturing with AI and advanced imaging.

Lumafield Raises $75M to Accelerate Next-Gen X-ray CT Solutions for Manufacturing

Lumafield, an industrial X-ray computed tomography (CT) technology pioneer located in the United States, has raised $75 million in a Series C funding round led by IVP. New investors G2 Venture Partners and Wellington Management, alongside Spark Capital, DCVC, Kleiner Perkins, Lux Capital, and Matter Venture Partners – who were all previously contacted – also participated. This investment is expected to bolster the company’s efforts to enhance large scale manufacturing capabilities, develop advanced CT systems, strengthen U.S. industrial innovation, and stabilize global supply chains.

Funding and Strategic Vision

The award highlights increased need for sophisticated quality inspection technologies in electric vehicles, medical devices, and even consumer goods. As Lumafield’s Co-Founder and CEO, Eduardo Torrealba shared his thoughts on the investment: ⌈ The U.S. needs “Cutting edge technology now more than ever to build resilient supply chains and dominate globally.”⌋ Also, the company informed about the hiring of Bill Cronin, former Xometry executive, as Head of Revenue. ⌊ This technology will redefine how quality is controlled and empower the manufacturers to create unprecedented products.⌋ Cronin recently served as Xometry’s VP after propelling the company’s sales from 2 million to 450 million and leading them to a 2021 IPO.

Technology and Market Impact

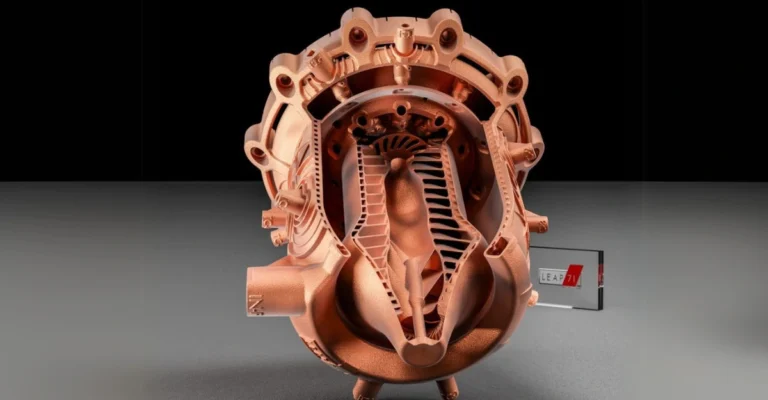

Lumafield’s CT scanners and integrated AI software allow engineers to accurately identify non-destructive defects which may otherwise go unnoticed, saving costly repairs and losses in the long run. Product Neptune is targeted towards R&D labs and alongside the Voyager analytics platform, a cloud-based service, and the Triton system, which operates factory-floor scans in 0.1 seconds, forms a complete package for efficient data collection. Through high-resolution CT, quality control becomes more central to a business model.

The firm noted an increase in annual recurring revenue (ARR) over the last two years which has tripled due to its widespread acceptance in various sectors. Importantly, 85% of its customers are new adopters of CT technology which shows a wider reach. “We’re making CT as routine as a spreadsheet,” added Torrealba illuminating the moves to advance access to sophisticated imaging.

Industry-Wide Advancements in X-ray CT

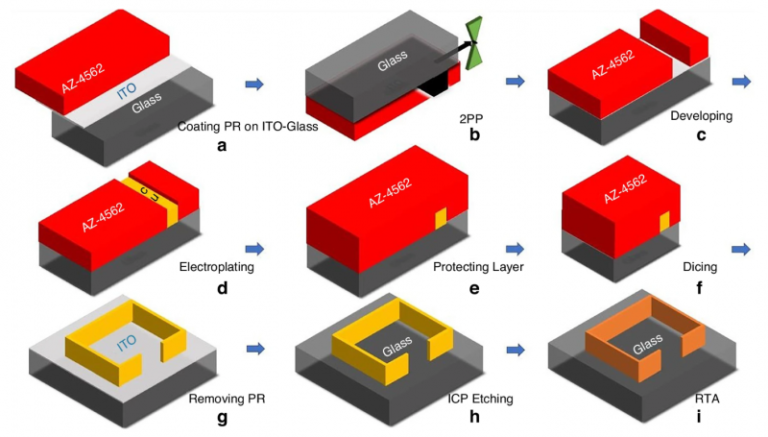

The Surge in X-ray CT Innovations Associated with the Manufacturing Sector has Enabled the Growth of Lumafield. A few years back in 2021, Carl Zeiss Industrial Metrology (ZEISS) had also collaborated with Oak Ridge National Laboratory for the development of AI-based CT systems designed for the analysis of 3D printed parts. As Dr. Pradeep Bhattad of ZEISS exclaimed, “AI-based CT could revolutionize non-destructive testing beyond additive manufacturing.” Similarly, in 2019 the Auburn University’s Center for Additive Manufacturing funded by NIST also purchased a CT system worth 1.5 million dollars to inspect aerospace components. Professor Bart prorok further elaborated, “This technology ensures accuracy in 3D imaging of metal parts for real-time verification in precision engineering.”

Read more : LulzBot Unveils TAZ 8 3D Printer With Larger Build and Better Precision

Future Outlook

Funding will allow Lumafield to expand its hardware and software solutions and pursue new partnerships with manufacturers looking to upgrade their QA processes. The cloud-based, low-cost infrastructure alongside integrated services provided by Lumafield keeps it at the front of the industrial metrology field. In the context of global industries focusing on supply chain resiliency, Lumafield technology becomes essential to maintaining a competitive advantage.

This round of funding reinforces Lumafield’s market leadership and also indicates a transition towards more sophisticated, data-centric manufacturing systems. Cronin’s seasoned leadership, coupled with IVP’s support, positions the company to rapidly advance innovation in their field, which is supremely competitive and unforgiving of missteps.

2 Responses