Researchers develop a 3D-printed, open-source robotic system to streamline material synthesis, cutting costs and enhancing accessibility.

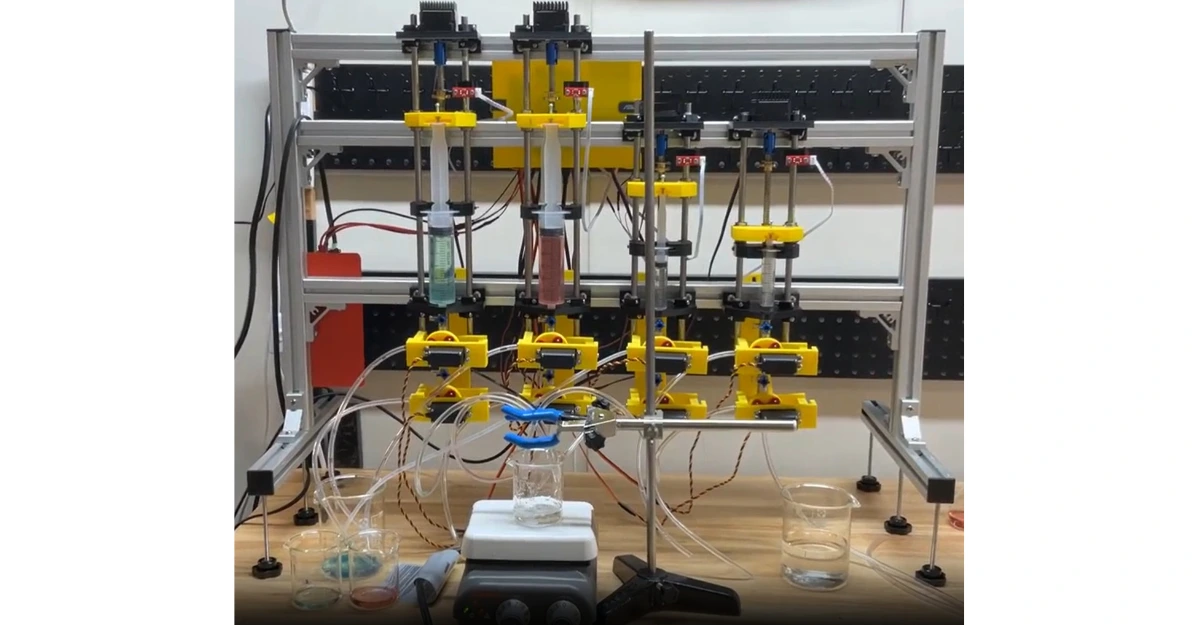

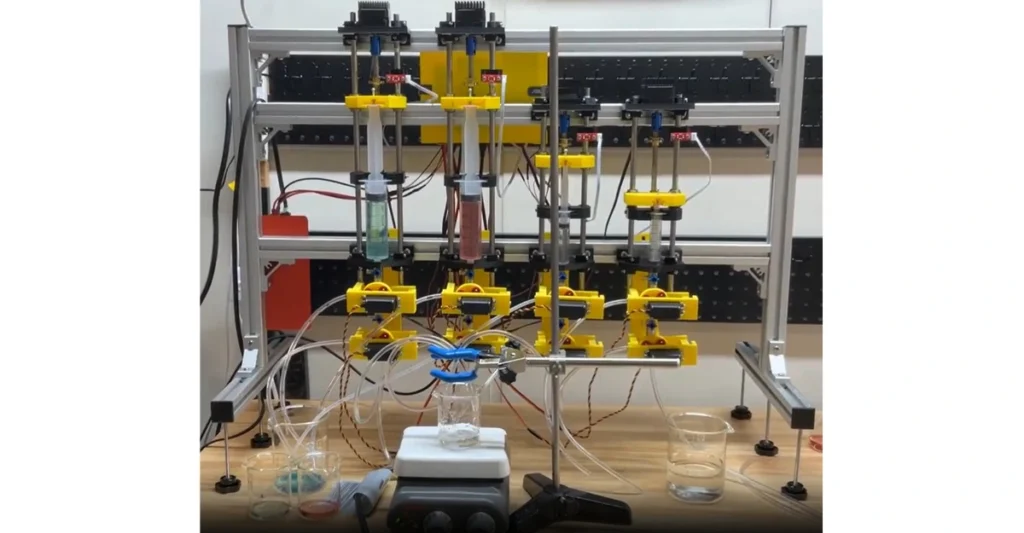

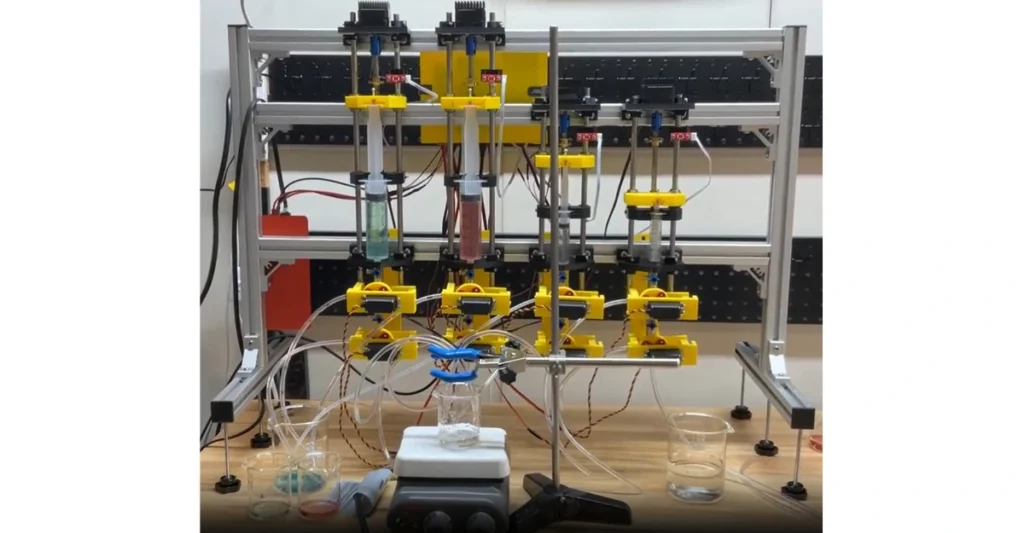

The 3D-printed robotic system called FLUID (Flowing Liquid Utilizing Interactive Device) was created by a group of researchers led by Professor Keisuke Takahashi at Hokkaido University to facilitate synthesizing on a material level. Designed with commercially available electronics and 3D-printed components, the open source robot strives to lower expenses and broaden availability of laboratory automation.

FLUID’s modular hardware includes four units, each with syringes, valves, servo motors, and stepper motors controlled by microcontroller boards. The system’s software allows users to adjust valve positions, syringe movements, and monitor real-time data. In a demonstration, FLUID automated the co-precipitation of cobalt and nickel, producing precise binary materials.

“By combining open-source designs, 3D printing, and affordable components, we’ve created a customizable tool for researchers with limited resources,” said Mikael Kuwahara, the study’s lead author.

The team has released all design files and software publicly, enabling researchers to replicate or modify FLUID for niche experiments. Future upgrades will add temperature and pH sensors to expand its capabilities to polymer mixing and organic synthesis.

Read more : Stanford Unveils Ultra-Fast Microscale 3D-Printing Method

“This system addresses gaps where commercial robots are too costly or unavailable,” Takahashi explained. Planned software enhancements include macro recording for repetitive tasks and improved data logging.

FLUID’s launch aligns with efforts to advance accessible automation in materials science, offering a scalable solution for global researchers.